Understanding Aluminum Alloys

Aluminum alloys are metals primarily made from aluminum combined with other elements to improve their properties. These alloys are widely used due to their lightweight, strength, and corrosion resistance. Understanding the different types of aluminum alloys is essential for selecting the right material for your CNC machining projects.

Classification of Aluminum Alloys

Aluminum alloys fall into two major categories based on how they are processed:

- Wrought vs Cast Aluminum

- Wrought aluminum is worked mechanically by rolling, extruding, or forging to create sheets, plates, or bars. It usually offers better mechanical properties and surface finish.

- Cast aluminum is melted and poured into molds. This method is often used for complex shapes but typically provides lower strength and machinability compared to wrought alloys. For more, see our guide on cast aluminum vs forged aluminum.

Another key classification is based on heat treatment capability:

- Heat-Treatable vs Non-Heat-Treatable Alloys

- Heat-treatable alloys can be strengthened through heating and controlled cooling processes, allowing higher strength and hardness.

- Non-heat-treatable alloys gain strength mainly through cold working like rolling or bending, generally offering better corrosion resistance but lower peak strength.

Aluminum Association Numbering System

The Aluminum Association classifies aluminum alloys by a four-digit system from 1xxx to 8xxx series, making it easier to identify the alloy’s general characteristics:

- 1xxx Series: Pure aluminum (99% or higher), excellent corrosion resistance, high ductility, low strength.

- 2xxx Series: Copper is the primary alloying element, high strength but lower corrosion resistance, commonly used in aerospace.

- 3xxx Series: Manganese added, good corrosion resistance and formability, typical for roofing and cooking utensils.

- 4xxx Series: Silicon alloy, used mainly for automotive and wear-resistant applications.

- 5xxx Series: Magnesium as the main element, excellent corrosion resistance, especially in marine environments.

- 6xxx Series: Magnesium and silicon, offering good strength, corrosion resistance, and machinability, popular in architectural and automotive.

- 7xxx Series: Zinc-based, very high strength, used for high-stress aerospace parts.

- 8xxx Series: Miscellaneous alloys, including lithium and other elements, used in specialty applications.

Key Properties of Aluminum Alloys

Choosing the right aluminum alloy depends on balancing key properties:

- Strength — Varies significantly among series; 7xxx and 2xxx series are very strong, while 1xxx is soft and malleable.

- Corrosion Resistance — Important for marine or outdoor use; 5xxx and 6xxx series excel here.

- Machinability — Some alloys cut and machine more easily, which impacts CNC precision and efficiency.

- Weldability — Some alloys, like 6xxx series, weld well, while others (like 2xxx and 7xxx) require special techniques.

- Cost — Pure aluminum (1xxx series) tends to be the cheapest; specialty high-strength alloys like 7075 cost more.

Understanding these fundamentals simplifies material selection and improves your CNC machining results.

Popular Aluminum Alloys for CNC Machining

When it comes to CNC machining aluminum, different alloys fit different needs. Here’s a quick look at the popular series used across industries:

1000 Series

- Almost pure aluminum (99%+).

- Excellent corrosion resistance and high thermal/electrical conductivity.

- Low strength but very easy to machine and form.

- Common in electronics and decorative parts.

200 Series

- Aluminum-copper alloys known for high strength

- Used heavily in aerospace for parts requiring toughness and lightweight.

- Less corrosion-resistant, often needs protective coatings.

- Great for high-stress applications but can be harder to machine.

3000 Series

- Manganese alloys with good formability.

- Ideal for sheet metal work and roofing.

- Moderate strength and good corrosion resistance.

- Common in food and beverage packaging.

5000 Series

- Aluminum-magnesium alloys noted for excellent corrosion resistance.

- Perfect choice for marine and automotive applications.

- Good weldability and moderate strength.

- Machinability can be moderate to low depending on the exact alloy.

6000 Series

- Aluminum-magnesium-silicon alloys offering great versatility.

- Excellent corrosion resistance and good strength.

- Widely used in architectural and structural components.

- Easy to machine, weld, and finish, making it a top pick for CNC machining.

7000 Series

- Zinc-based alloys with the highest strength among aluminum alloys.

- Used in aerospace and high-stress sporting equipment.

- Lower corrosion resistance, typically requires anodizing or plating.

- Machining requires skill but delivers outstanding performance.

| Alloy Series | Tensile Strength (ksi) | Density (g/cm³) | Corrosion Resistance | Machinability | Cost | Typical Applications |

|---|---|---|---|---|---|---|

| 1000 | 13-19 | 2.7 | Excellent | Excellent | Low | Electronics, cookware |

| 2000 | 40-60 | 2.78 | Fair | Fair | Medium | Aerospace, military |

| 3000 | 20-35 | 2.73 | Good | Good | Low | Roofing, packaging |

| 5000 | 25-45 | 2.66 | Excellent | Moderate | Medium | Marine, automotive |

| 6000 | 25-45 | 2.7 | Good | Excellent | Medium | Structural, architectural |

| 7000 | 60-83 | 2.81 | Fair | Moderate | High | Aerospace, sports gear |

Understanding these options helps you pick the right aluminum alloy depending on your CNC machining needs—whether that’s easy shaping, high strength, corrosion resistance, or cost-efficiency.

Key Factors for Choosing an Aluminum Alloy

When picking the right aluminum alloy for your project, several key factors come into play:

-

Strength-to-weight ratio

This is crucial, especially for parts that need to be both strong and lightweight. High strength with less weight means better performance without adding bulk, which is why alloys like 7075 and 6061 are popular in aerospace and automotive sectors.

-

Corrosion resistance

If your parts will face harsh environments—like saltwater or chemicals—choosing a corrosion-resistant alloy is a must. Alloys in the 5000 series, like 5052, offer great protection against rust and wear over time.

-

Machinability

How easily an aluminum alloy can be machined affects CNC precision and production efficiency. Alloys like 6061 and 1100 are known for smooth machining, helping reduce tool wear and shorten turnaround times.

-

Cost

Balancing material performance with budget limits is important. For example, 1000 series alloys are affordable but lack strength, while 7000 series packs high strength at a higher price. Choose wisely based on what you really need.

-

Formability and weldability

Some projects need complex shapes or welded assemblies. Alloys like 3003 and 6061 are easier to form and weld, making them go-to choices for custom parts requiring different fabrication steps.

-

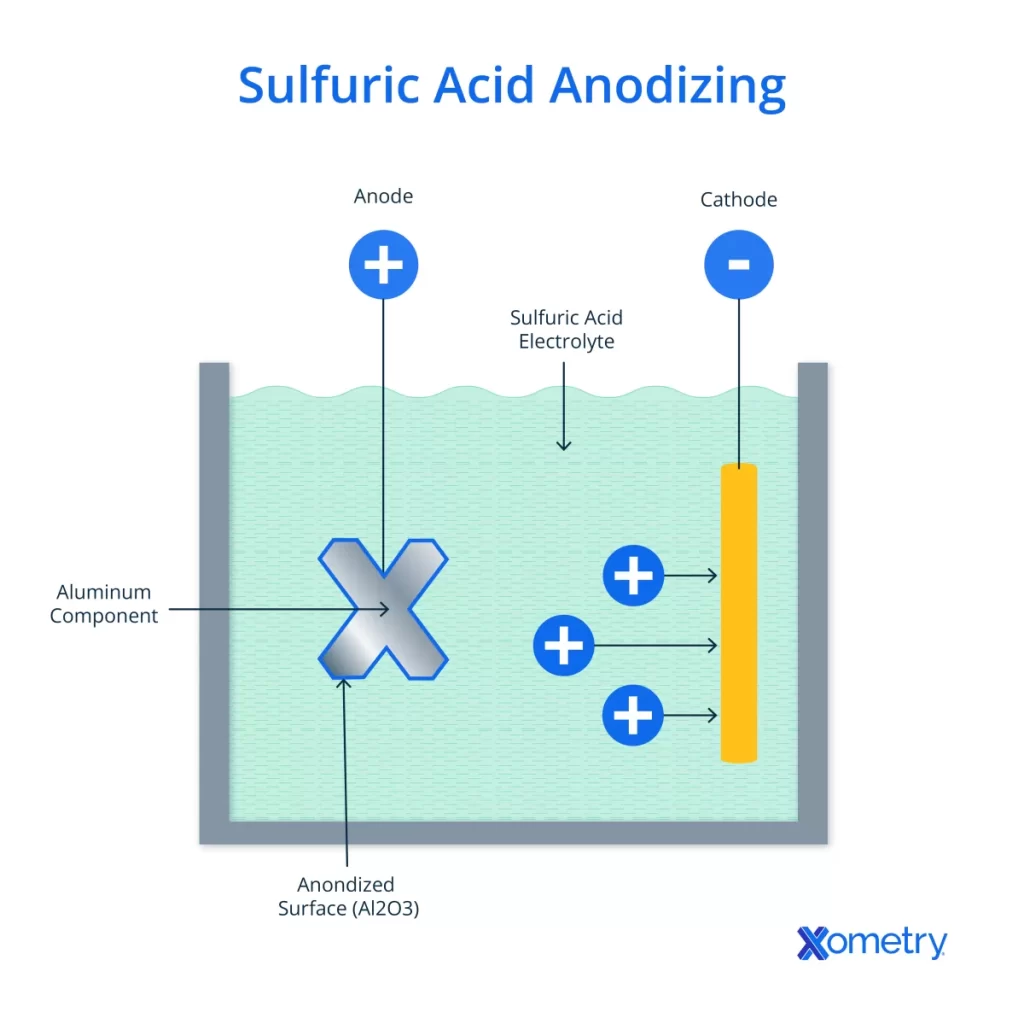

Surface finishing options

Finishing isn’t just about looks—it impacts durability and corrosion resistance. Aluminum alloys respond well to finishing methods like anodizing, powder coating, and plating. These options can add value and protection to your CNC-machined parts.

Focusing on these factors will help you zero in on the best aluminum alloy that meets your specific needs without overspending or compromising quality.

Applications of Aluminum Alloys in CNC Machining

Aluminum alloys are a go-to for CNC machining because they balance strength, weight, and workability well. Here’s where some popular alloys shine in real-world use:

-

Aerospace

7075 and 2024 alloys are top picks. They offer high strength and good fatigue resistance, making them ideal for aircraft frames, structural parts, and high-stress components where durability matters most.

-

Automotive

6061 and 5052 alloys are widely used. 6061 works great for engine components, brackets, and frames thanks to its strength and machinability. Meanwhile, 5052’s strong corrosion resistance suits parts exposed to moisture, like fuel tanks and body panels.

-

Construction

6063 alloy stands out in architectural and structural applications. Its excellent formability and corrosion resistance make it perfect for window frames, door frames, and lightweight structural parts in buildings.

-

Electronics

The 1100 series is popular here. It’s soft, highly conductive, and easy to machine, often used for housings, heat sinks, and shielding in electronic devices.

Case Study: Custom Automotive Part Using 6061

Imagine you need a custom lightweight bracket for a classic car restoration. Choosing 6061 means:

- Strong enough to handle stress but still easy to machine with precision

- Good corrosion resistance to last without heavy coatings

- Compatible with common finishing processes like anodizing for a clean look

This makes 6061 a solid choice balancing performance, cost, and manufacturing ease for custom automotive parts.

Whether you’re building aerospace components or custom parts, understanding each alloy’s strengths helps you pick the right one for your CNC machining project.

How HYCNC Helps You Choose the Right Alloy

Choosing the right aluminum alloy can be tricky, but at HYCNC, we make it simple. Our expert team offers tailored consultations to match your project needs with the best alloy options. Whether you need 6061 for versatility or 7075 for strength, we guide you through the selection based on your priorities like strength, corrosion resistance, and budget.

We handle precision CNC machining for all aluminum grades, ensuring your parts come out exactly how you want Plus, our quick quoting and prototyping services let you test alloy choices without delays, helping you find the perfect fit faster.

Ready to get started? Contact HYCNC today for a free consultation or quote and see how we can support your project with the right aluminum alloy.