What Is Anodizing Aluminum

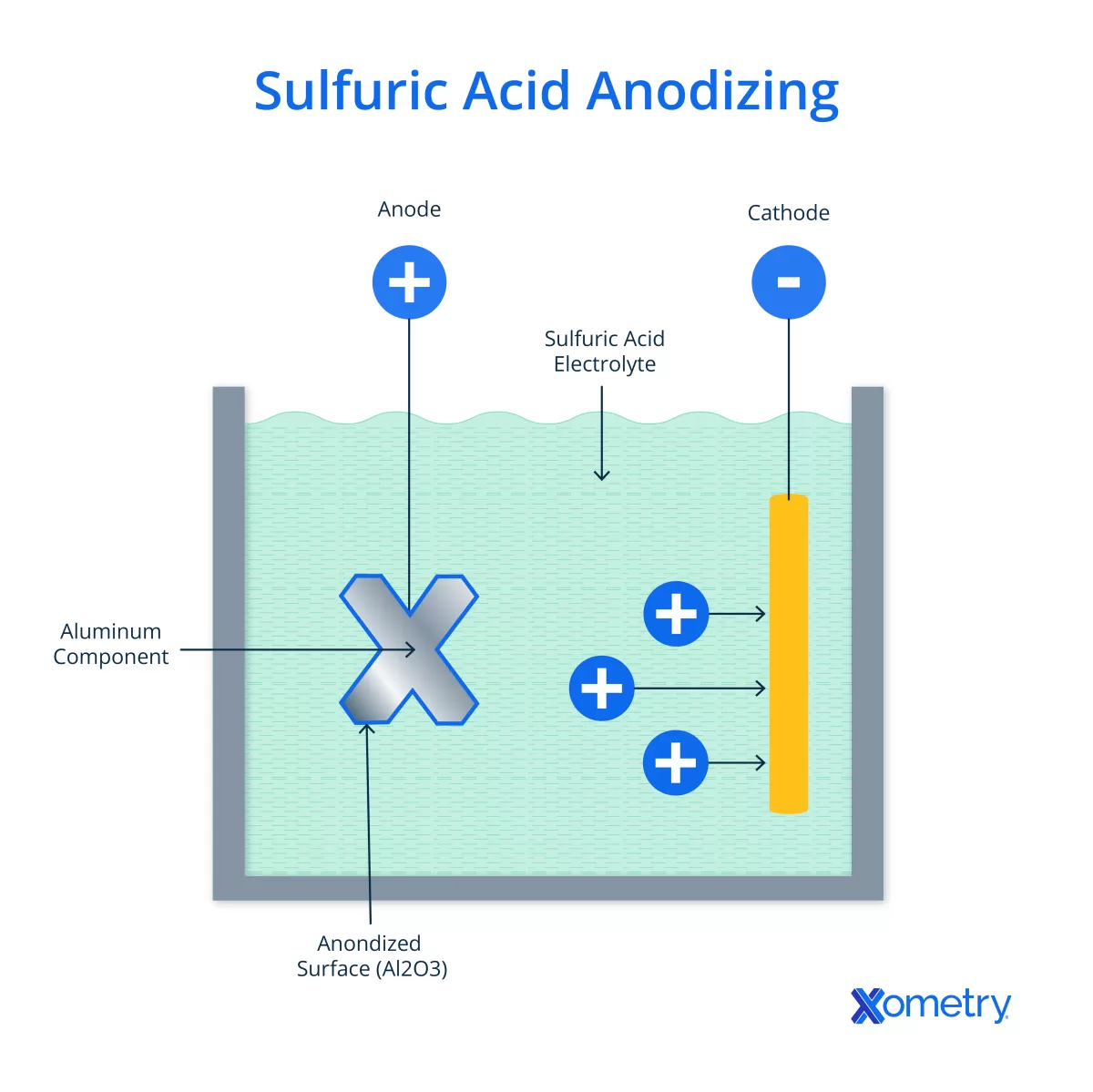

Anodizing aluminum is an electrochemical process that enhances the natural oxide layer on the surface of aluminum parts. This thickened oxide layer protects the metal from corrosion and wear, while also improving its appearance. The process involves immersing aluminum in an acid electrolyte bath and passing an electric current through it. This causes oxygen to form on the aluminum surface, creating a durable, controlled oxide coating.

Process Steps

- Cleaning – The aluminum is thoroughly cleaned to remove dirt, grease, and impurities.

- Etching – The surface is etched to prepare it for uniform oxide growth.

- Anodizing – The aluminum is placed in an acid bath (commonly sulfuric acid) and electric current is applied, forming a porous oxide layer.

- Sealing – The porous layer is sealed by hydrating it, locking in properties like corrosion resistance and color.

Types of Anodizing

- Sulfuric Acid Anodizing – The most common type, producing a balanced, durable coating suitable for many applications.

- Hard Anodizing – Also called hardcoat anodizing, it forms a thicker and harder surface used when extra wear resistance is needed.

- Chromic Acid Anodizing – Produces a thinner coating, ideal for aerospace parts requiring minimal dimensional changes.

- Color Anodizing – Adds dyes to the porous oxide layer for decorative finishes in various colors.

Each type offers different benefits, making anodizing a versatile aluminum surface treatment used across many industries.

Benefits of Anodizing Aluminum

Anodizing aluminum offers several key benefits that make it a popular choice across many industries.

Corrosion resistance

The anodizing aluminum process creates a protective oxide layer on the surface, which greatly improves corrosion resistance. This means parts last longer, especially in harsh environments like coastal areas or chemical exposure.

Wear resistance

Anodized aluminum is much harder and more wear-resistant than untreated metal. This makes it ideal for applications where parts face frequent contact or friction, helping reduce maintenance and replacement costs.

Aesthetic appeal

Anodizing enhances the look of aluminum by giving it a smooth, consistent finish. It also allows for coloring without fading, so products can maintain a fresh, vibrant appearance over time.

Increased surface area

The anodized layer is porous, increasing the surface area. This is great for paint or adhesive bonding, making aluminum easier to work with in manufacturing and assembly.

Non-conductive properties

Unlike bare aluminum, anodized aluminum becomes electrically non-conductive due to the oxide coating. This is useful in electronics or applications where insulation is needed.

These benefits combine to make anodizing aluminum a smart surface treatment that extends life, improves durability, and supports a range of uses in industries like aerospace, automotive, and consumer goods.

How Anodizing Aluminum Is Used in Laser Cutting

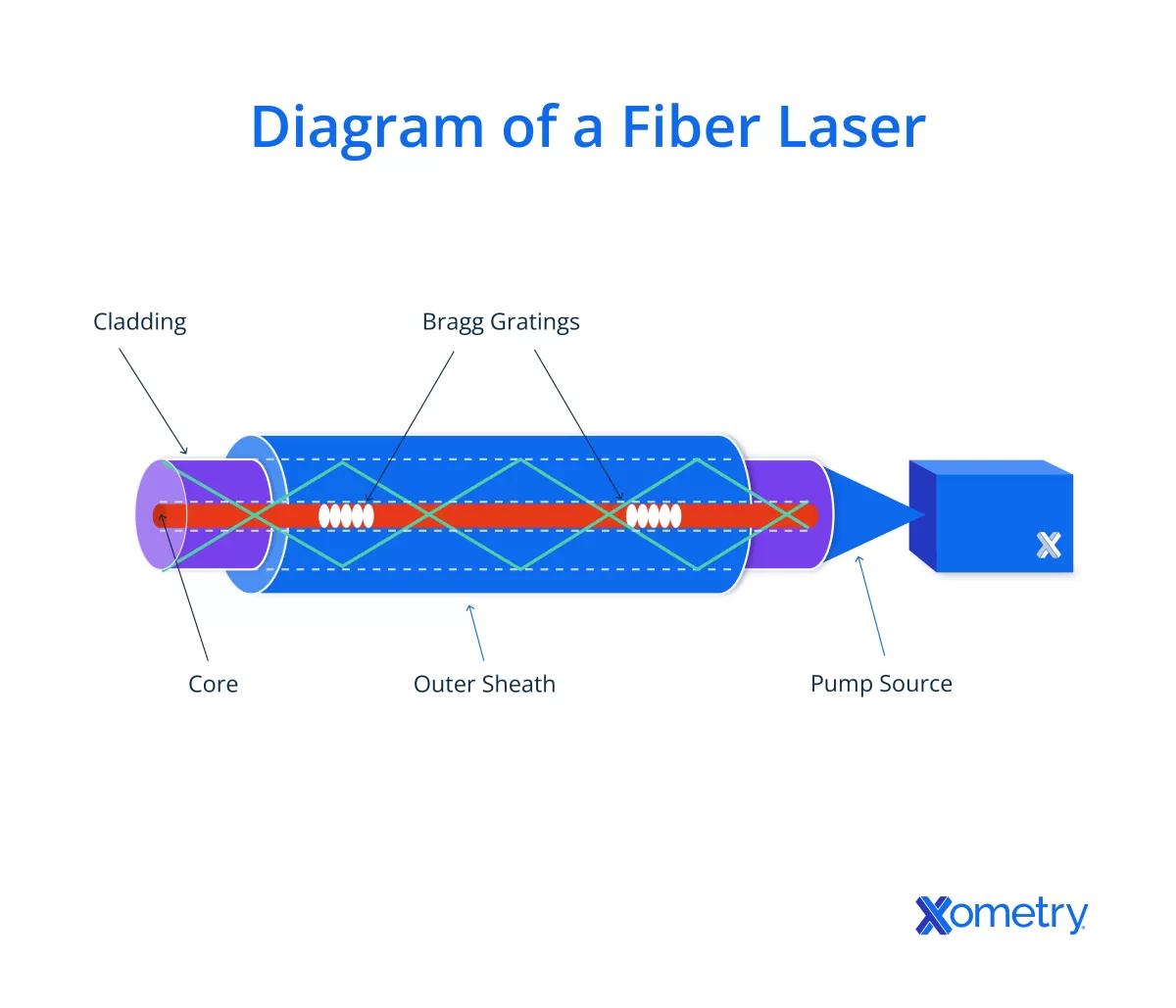

Laser cutting is a precise method that uses a focused laser beam to cut or engrave materials like aluminum. It’s popular because it delivers clean edges and detailed designs without much waste.

When it comes to anodized aluminum, laser cutting works well but needs some care. Since anodizing creates a hard, corrosion-resistant oxide layer on the surface, the laser interacts differently compared to bare aluminum. This means the laser settings often need tweaking to cut through the anodized layer smoothly without damaging the material underneath.

Anodized aluminum finds its way into many industries using laser cutting:

- Aerospace: Lightweight and corrosion-resistant parts are essential for aircraft.

- Automotive: Durable, attractive components and trim pieces.

- Consumer goods: Gadgets, electronics, and household items benefit from anodized finishes.

- Signage: Anodized aluminum signs stand out with vibrant colors and weather resistance.

However, laser cutting anodized aluminum is not without challenges. The hard anodized layer can cause uneven cutting or leave residues, especially if the laser power and speed aren’t dialed in correctly. Also, the anodized surface may produce fumes during cutting, so proper ventilation is important.

In short, anodizing aluminum works hand-in-hand with laser cutting, provided you understand the material’s unique properties and adjust the process accordingly.

Best Practices for Laser Cutting Anodized Aluminum

When working with anodized aluminum, following the right steps ensures clean cuts and preserves the material’s quality. Here’s what you need to keep in mind:

Preparation of Parts

- Clean the surface thoroughly to remove contaminants that could affect cutting.

- Inspect the anodized layer for any inconsistencies or damage before cutting.

- Secure the parts properly to avoid movement during laser cutting, which can cause uneven edges.

Laser Settings Adjustment

- Lower the laser power slightly compared to bare aluminum to avoid burning through the anodized layer too fast.

- Increase the cutting speed to reduce heat buildup and prevent warping or discoloration.

- Fine-tune focus for sharper cuts since anodized surfaces can reflect lasers differently.

Two-Pass Technique

- Use a two-pass cutting method: the first pass removes most of the anodized coating, and the second pass cuts through the base aluminum cleanly.

- This approach helps minimize excessive heat buildup and improves edge quality.

Handling Hard Anodizing

- Hard anodized aluminum has a thicker, denser coating, making laser cutting more challenging.

- Adjust the laser power and speed to allow more energy for penetrating the hard anodized layer without overheating the substrate.

- Consider multiple passes with lower power to maintain precision and avoid damaging the aluminum underneath.

Following these best practices ensures your laser cutting on anodized aluminum is precise, efficient, and results in high-quality finished parts. For more laser cutting insights, you might find our guide on what is laser cutting helpful.

When to Avoid Anodizing Before Laser Cutting

There are times when anodizing aluminum before laser cutting isn’t the best move. Here’s when you might want to skip it:

-

If the anodized layer needs removal after cutting: Some projects require stripping the anodized coating after laser cutting, which adds extra work and cost. In these cases, it’s better to laser cut raw aluminum first, then anodize after finishing.

-

When electrical conductivity is important: Anodizing creates a non-conductive surface. So, if your part needs to conduct electricity—like in electronics or some automotive applications—avoid anodizing before laser processing.

-

For precise finishing sequences: Sometimes manufacturing requires specific orders of surface treatment and cutting. Consulting early on about the finishing steps can save time and issues later. It helps to plan whether anodizing fits before or after laser cutting to get the best results.

Knowing when to anodize comes down to the part’s use and the needs for conductivity or post-processing. This keeps your project efficient and cost-effective. For more insights on cutting methods and part prep, check out our guide on common laser processing methods.

Why Choose HYCNC for Anodizing and Laser Cutting

At HYCNC, we bring together years of expertise and the latest advanced equipment to deliver top-notch anodizing and laser cutting services. Our team understands the unique challenges involved in working with anodized aluminum and uses precision CNC machining to ensure every project meets high standards.

We offer customized solutions tailored to various industries, including aerospace, automotive, consumer goods, and signage. Whether you need corrosion-resistant aluminum parts or detailed laser engraving aluminum, our processes are designed to fit your specific application and requirements.

Quality control is a priority for us. From the initial preparation of parts to the final cut, we maintain strict checks to guarantee consistent results. We focus on customer satisfaction by communicating clearly and delivering on time, making HYCNC your trusted partner for aluminum anodizing process and precision cutting anodized aluminum services in the US market.