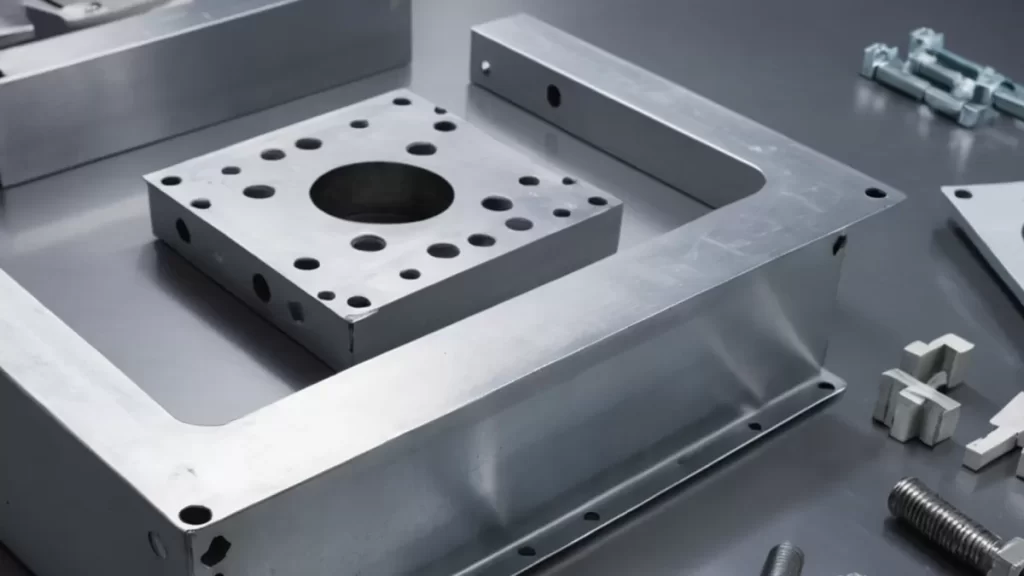

Introduction Understanding Metal Burrs in CNC Machining

If you’ve ever dealt with metal parts that have rough, unwanted edges, you’ve encountered metal burrs. Simply put, metal burrs are small, sharp fragments or raised edges that form on a metal workpiece during machining processes like cutting, drilling, or milling. These tiny imperfections may seem minor, but they can cause major headaches in metalworking by affecting the overall quality, safety, and functionality of your parts.

In CNC machining, burrs most often appear due to tool wear, improper cutting parameters, or the natural deformation of metal as it’s shaped. For example, when a cutting tool passes through metal, it can leave behind burrs where the material tears or folds instead of a clean cut. This happens frequently in operations like drilling holes, milling edges, or turning parts.

Why do burrs matter? Beyond making parts look unfinished, they can lead to assembly problems, reduce the lifespan of components, and even pose safety risks like cuts or equipment damage. Burrs also slow down manufacturing because additional deburring steps become necessary to meet strict quality standards.

At HYCNC, we understand these challenges deeply. Our advanced CNC machining services don’t just cut metal precisely — we integrate specialized burr detection and removal techniques to ensure your parts come out clean and ready to perform. By combining expert process control with the latest deburring tools, we help you avoid costly delays and deliver flawless, burr-free metal components that meet your industry’s exacting standards.

Types of Metal Burrs and Their Challenges

Metal burrs come in different shapes, and knowing these types helps a lot when it’s time to remove them properly.

Poisson Burrs

These burrs are raised edges that form on the opposite side of a cut or drill due to metal displacement. They’re common when the metal stretches during machining. Poisson burrs can cause rough surfaces and need precise removal to avoid damaging the part.

Roll-Over Burrs

Typical in drilling and milling, roll-over burrs look like rolled or folded edges along the cut. They happen when the cutting tool pushes the metal instead of cleanly cutting it. These burrs often require grinding or manual tools to smooth them out.

Tear Burrs

Tear burrs appear mostly on softer metals where the material tears instead of cutting cleanly. They create jagged, uneven edges that can be sharp and unsafe. Removing tear burrs often needs delicate handling to prevent further damage.

Breakout Burrs

Found in precision parts, breakout burrs occur at edges where the metal breaks off unevenly. They’re a big challenge in high-accuracy jobs because they affect fit and function. Identifying these burrs early means using careful deburring methods to keep parts within tight tolerances.

Why Identifying Burr Types Matters

Recognizing the specific type of burr is key to picking the right deburring method. Using the wrong technique can waste time, damage parts, or leave rough edges. At HYCNC, we always start by identifying burr types to deliver clean, precise finishes every time.

Effective Methods for Metal Burr Removal

When it comes to removing metal burrs, there’s no one-size-fits-all solution. You want a method that fits your metal type, part design, and production needs. Here’s a quick look at common burr removal methods and how HYCNC uses them to keep your parts sharp and clean.

Manual Deburring

This is the classic way with files, scrapers, and brushes. It works great for small batches or touch-ups where precision is key and the burrs aren’t too stubborn. Manual deburring gives you control but takes more time and skill.

Pros:

- Precise for small jobs

- Low cost upfront

- Easy to start without complex setup

Cons:

- Labor-intensive

- Not ideal for high volumes

- Risk of inconsistent quality

Mechanical Deburring

This includes grinding, tumbling, and abrasive blasting—all good for bigger batches or tougher burrs. They remove burrs quickly and evenly across many parts but can sometimes affect fine details on delicate pieces.

Pros:

- Efficient for large runs

- Consistent finish

- Suitable for tougher burrs

Cons:

- May round edges more than desired

- Setup time and cost can be higher

- Not as precise for intricate parts

Automated CNC Deburring

HYCNC shines with this approach. Our advanced CNC machines handle automated deburring with high accuracy, perfect for parts that demand tight tolerances without manual intervention. It speeds up production while ensuring every edge is burr-free.

Pros:

- High precision

- Fast and repeatable

- Integrates well with existing CNC workflows

Cons:

- Initial investment required

- Best used for medium to large volumes

Thermal and Electrochemical Deburring

These specialized methods use heat or chemical processes to remove burrs, ideal for complex shapes and hard-to-reach spots. Thermal deburring burns away burrs quickly, while electrochemical deburring dissolves them without damaging the base metal.

Pros:

- Works on complex and delicate parts

- Leaves smooth, clean edges

- Minimal mechanical stress

Cons:

- Equipment and process cost can be high

- Not suitable for all metal types

- Requires safety precautions

Choosing the Right Method

At HYCNC, we evaluate your project’s metal type, part geometry, and production volume to pick the best burr removal method. Sometimes a combination works best—like an initial mechanical deburr followed by automated CNC finishing—to get the cleanest, safest parts on time.

No matter what method we use, the goal stays the same: flawless parts, ready for real-world use without compromising quality or safety.

Why Choose HYCNC for Burr-Free CNC Machining

At HYCNC, we specialize in precision CNC machining that focuses on delivering burr-free metal parts you can trust. Our advanced deburring technology is designed to tackle even the toughest burr challenges, ensuring every cut, drill, and mill is clean and flawless.

We understand every industry has unique demands. That’s why we offer tailored solutions for sectors like aerospace, automotive, and medical, where accuracy and safety are non-negotiable. Our custom setups and expert team guarantee parts meet the strictest standards.

For example, we worked with a client on a high-precision aerospace project struggling with burr buildup during milling. By integrating our specialized deburring processes with CNC cutting tools optimized for their exact materials, we cut burr presence dramatically. This boosted their product quality and reduced post-production time.

With HYCNC, you get more than just parts—you get reliable, burr-free results that help your business run smoother and safer.

Best Practices for Preventing Metal Burrs

Preventing metal burrs starts with fine-tuning your CNC machine settings. Adjusting spindle speed and feed rate can make a big difference—too fast or too slow can cause rough edges or excessive burrs.

Choosing the right cutting tools is just as important. Different metals require specific CNC cutting tools for clean cuts. For example, using carbide burrs on harder metals helps reduce burr formation.

Regular maintenance of your CNC equipment is key to keeping burrs at bay. Dull tools or worn-out components often lead to more burrs and lower metalworking precision.

At HYCNC, we take a proactive approach to burr prevention. We meticulously optimize machine parameters and select the best deburring tools tailored for each project. This strategy not only cuts down on burrs but also boosts overall manufacturing efficiency for our US clients needing consistent, high-quality parts.

For more insights on metal cutting tools, check out our detailed guide on CNC metal cutting tools.

Tools and Equipment for Deburring What to Consider

When it comes to removing metal burrs, having the right tools makes all the difference. Here’s a quick look at some common options and how to choose what fits your needs best.

Carbide Burrs and Rotary Tools Features and Benefits

- Carbide burrs are small rotary tools made from tough tungsten carbide. They cut cleanly and last long, making them great for precision deburring on hard metals.

- These tools spin fast and can shape or smooth edges with fine control.

- Ideal for detailed work, they handle complex designs and tight spots well.

Manual vs Automated Deburring Tools

- Manual tools like files, scrapers, and brushes are simple, affordable, and perfect for small jobs or delicate parts. They give hands-on control but take more time and skill.

- Automated tools use machines such as grinders, tumblers, or CNC deburring setups to do the work faster and more consistently. They cut down on labor and reduce human error.

- For high-volume or high-precision jobs, automated methods usually deliver better efficiency and uniform results.

How HYCNC Integrates Top-Tier Deburring Tools

At HYCNC, we combine skilled manual techniques with advanced automated deburring equipment to handle any burr challenge. Our investments in carbide burrs and CNC-enabled deburring systems ensure every part meets strict quality standards with minimal rework.

Tips for Selecting the Right Deburring Equipment

- Match the tool to your material—hard metals call for carbide burrs, softer metals for gentler options.

- Consider the size and complexity of your parts. Small, intricate pieces often need rotary burrs or manual tools. Larger or bulk batches benefit from automated solutions.

- Think about your volume—manual tools suit low runs, automation shines with mass production.

- Factor in cost and maintenance to balance upfront investment with long-term efficiency.

Using the right deburring tools keeps your metal parts clean, smooth, and ready for their next step—saving time and money in production.

The Role of Burr Removal in Industry Standards

Metal burr removal isn’t just about making parts look good—it’s a key part of meeting strict industry standards. Quality standards like ISO and ASME require manufacturers to deliver parts free of burrs to ensure safety, reliability, and consistent performance. Burrs can cause assembly issues, wear down other components, or even create safety risks in critical applications like aerospace, automotive, and medical devices.

At HYCNC, we take these regulations seriously. Our advanced CNC machining and deburring processes are designed to meet or exceed industry requirements. We use precision deburring tools and thorough quality checks to ensure every part leaves our facility free of burrs and ready for use in safe, high-demand environments. This commitment helps our clients stay compliant and maintain top product quality.

FAQs about Metal Burrs and Deburring

What causes metal burrs in CNC machining

Metal burrs happen when the cutting tool removes material but leaves rough edges behind. Common causes include improper cutting speed, dull tools, high feed rates, and machining harder metals. Processes like drilling, milling, and turning can create burrs if the machine or settings aren’t spot-on.

How does HYCNC ensure burr-free parts

At HYCNC, we use advanced CNC machining combined with precision deburring technology. Our team optimizes cutting parameters and performs thorough quality checks. Automated deburring and specialized tools help us deliver metal parts free from burrs, ensuring better product quality and safety.

What are the best tools for deburring metal

It depends on the job, but common tools include:

- Manual options like files, scrapers, and brushes for small or detailed work

- Mechanical options like grinders and tumblers for larger batches

- Carbide burrs and rotary tools for precision shaping

- Automated CNC deburring systems for consistency on complex parts

Can manual deburring be as effective as automated methods

Manual deburring works well for small jobs and touch-ups but isn’t as consistent or fast as automated methods. For high-volume or precision projects, automated deburring at HYCNC offers better accuracy and repeatability.

How can I prevent burrs in my CNC projects

Preventing burrs starts with the right setup:

- Use sharp, high-quality cutting tools

- Optimize spindle speed and feed rates based on the metal type

- Maintain equipment regularly to avoid tool wear

- Plan machining strategies that reduce stress on edges

For tips on choosing the right CNC cutting tools, check out our guide on CNC metal cutting tools.