Understanding Precision in Sheet Metal Fabrication

Precision in sheet metal fabrication means creating parts that match exact dimensions and tolerances every time. It’s about controlling variations so parts fit perfectly in assemblies without extra adjustments. Achieving this level of accuracy is essential in industries like aerospace, automotive, and electronics where tight tolerances impact performance and safety.

Why is precision so important? Precise sheet metal parts ensure reliability, reduce waste from errors, and lower costs due to fewer reworks. They also improve the overall product quality and customer satisfaction.

However, reaching high precision can be challenging. Common issues include material inconsistencies, inaccurate bend allowances, tool wear, and deformation during forming or cutting. Each of these factors can cause deviations from design specs, making it harder to maintain tight tolerances without proper control and planning.

Key Strategies to Enhance Precision in Sheet Metal Parts

To boost precision in your sheet metal parts, start with the right material. Optimize material selection by choosing metals with consistent thickness and good formability. This reduces unexpected shifts during fabrication.

Next, leverage advanced CNC technologies like CNC laser cutting and CNC machining. These tools offer tight tolerances and repeatability, helping you nail exact dimensions every time.

Always follow design for manufacturability (DFM) guidelines. That means designing parts with realistic bend allowance calculations and proper spacing to avoid errors or deformations during bending or cutting.

Implement a robust quality control process. Regular inspections and measurements catch issues early, so you can correct mistakes before they turn into costly problems.

Finally, focus on minimizing deformations and errors by controlling factors like machine settings, material handling, and tooling wear. Consistency in these areas helps maintain the precision your project demands.

Advanced Techniques for Precision

To really boost precision in your sheet metal parts, it’s smart to lean on advanced techniques that bring accuracy and consistency to the table.

Incorporate Automation

Automation reduces human error and speeds up production. Using automated CNC machines ensures every cut, bend, or punch follows exact specs without slip-ups. Robotic arms and automated material handling also improve repeatability, which means tighter sheet metal tolerances every time.

Utilize CAD CAM Software

CAD CAM software bridges design and manufacturing perfectly. You can create detailed models and simulate the fabrication process to spot issues before production starts. This helps optimize designs for manufacturability, fine-tune bend allowance calculations, and program CNC machines precisely — leading to better CNC machining precision and fewer costly mistakes.

Explore Additive Manufacturing

While not traditional for sheet metal, additive manufacturing is catching on for complex parts or prototypes. It allows creating intricate shapes that are hard to achieve with conventional methods. Combined with CNC machining, it can enhance precision by producing accurate prototypes and tooling aids that improve the overall fabrication workflow.

By adopting these advanced techniques, you’ll get better control and tighter precision in your sheet metal fabrication projects, saving time and costs while delivering high-quality results.

Common Mistakes to Avoid

When working on sheet metal fabrication, skipping key details can hurt precision and quality. Here are some common slip-ups to watch out for:

-

Ignoring Bend Allowances

Not accounting for bend allowances leads to parts that don’t fit right. Bending metal changes its dimensions, so calculating the right allowance is critical. Skipping this will cause misalignment and costly rework.

-

Placing Features Too Close to Bend Lines

Features like holes or cutouts positioned too close to bends risk distortion or cracking during forming. Keep a safe distance from bend lines to maintain strength and accuracy.

-

Ignoring Grain Direction

Sheet metal has a grain that affects how it bends and stretches. Overlooking grain direction can cause uneven bends and weak spots. Aligning your design with the grain improves durability and looks cleaner.

-

Neglecting Surface Finish

Surface finish impacts both the aesthetic and functional quality. Rough or inconsistent finishes can cause issues during assembly or the final look. It’s important to specify and control finish quality, especially in visible parts.

Avoiding these mistakes upfront saves time and ensures parts meet the tight tolerances needed in precision sheet metal fabrication. For more on quality and finishing, check out our post on good surface finish for CNC machined parts.

How HYCNC Ensures Precision in Sheet Metal Fabrication

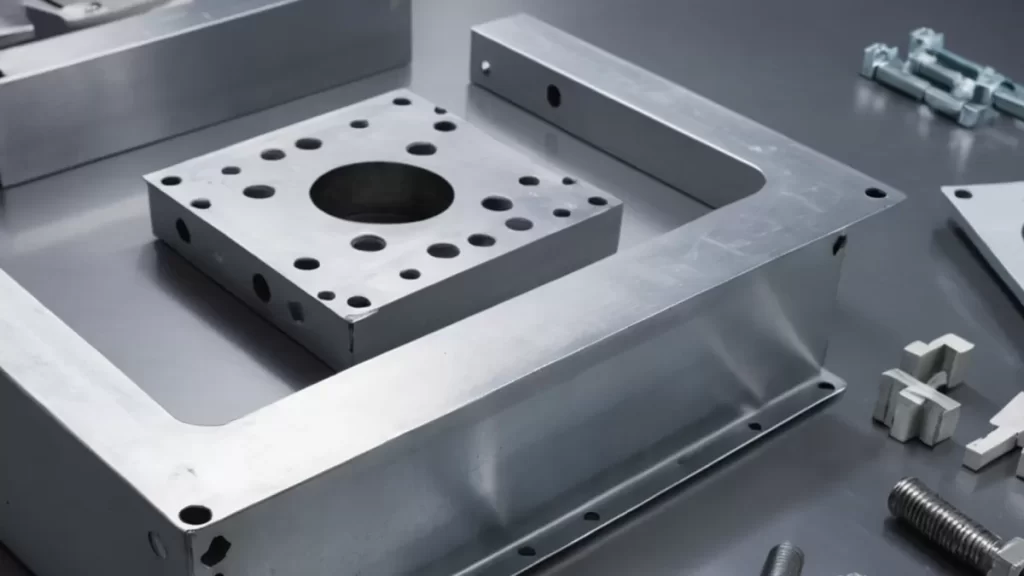

At HYCNC, precision in sheet metal parts isn’t just a goal—it’s a standard. We combine state-of-the-art CNC machining precision with years of experience to deliver parts that meet tight tolerances and exact specifications. Our advanced CNC laser cutting, precision bending techniques, and thorough quality control processes ensure every part leaves our facility ready for your next step.

For example, a recent project involved fabricating complex enclosures with strict bend allowance calculations and close tolerance features. Using our automated CNC systems and design for manufacturability guidance, we minimized errors and maintained consistent quality throughout the run, saving the client time and extra costs.

If you’re looking to add precision to your sheet metal parts, HYCNC has the expertise and technology to help. Reach out today to see how we can improve your fabrication process and get parts made exactly the way you need them.

FAQs About Adding Precision to Your Sheet Metal Parts

What are standard tolerances in sheet metal fabrication?

Standard tolerances usually range from ±0.005 to ±0.020 inches depending on the process and thickness. Tight tolerances mean less wiggle room, which is critical for parts that must fit perfectly.

How does material choice affect precision?

Materials like aluminum and stainless steel behave differently during bending and cutting. Some metals are more prone to warping or spring back, so picking the right material helps keep parts accurate.

What are the best CNC tools for precision sheet metal work?

High-quality CNC laser cutters and press brakes with CNC control systems deliver the most reliable precision. Tools that offer repeatability and fine control over cutting speed and bend angles are key.

How can HYCNC help with my sheet metal project?

HYCNC offers advanced CNC machining services focused on tight tolerances and consistent quality. With expert support, they help optimize your design, select the right materials, and ensure each part meets exact specs.

Can HYCNC handle complex or custom precision parts?

Absolutely. Their experience with CAD CAM software and automation allows them to take on intricate designs. They work closely with you to avoid common issues like deformation and achieve your project goals.