Are you debating between thread tapping and thread milling for your CNC machining project? Choosing the right threading method can transform your production efficiency and component quality. As a machining professional, I’ve seen firsthand how the right choice impacts precision, cost, and turnaround time. At HYCNC, we specialize in delivering top-tier CNC threading solutions tailored to your needs. In this guide, we’ll break down the differences, pros, and cons of thread tap vs thread mill, empowering you to make a smart decision. Let’s dive in and find the perfect threading approach for your next project!

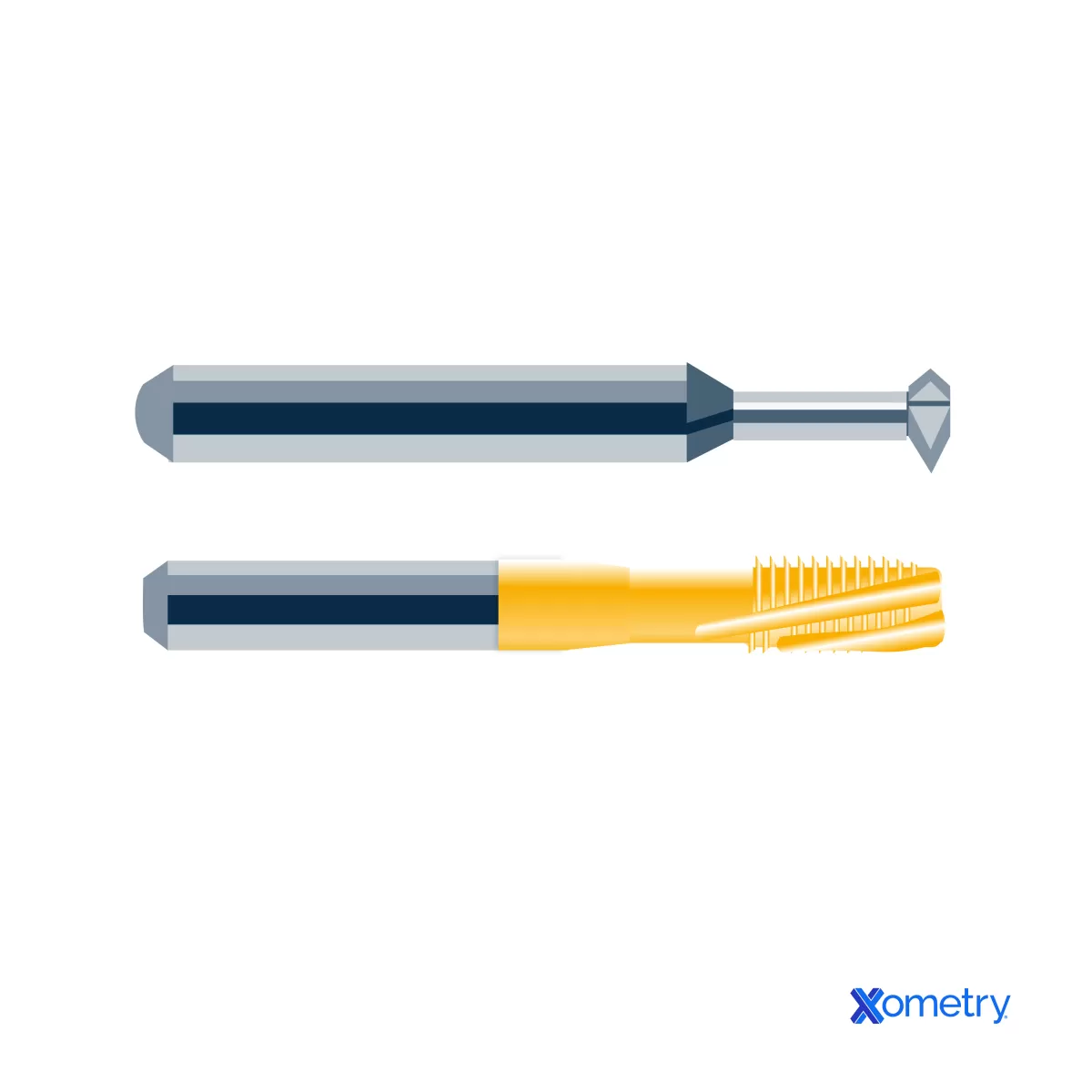

What is Thread Tapping

Thread tapping is the process of cutting internal threads into a pre-drilled hole using a tool called a tap. This creates a precise threaded hole that allows screws or bolts to fasten securely. It’s one of the most common methods for creating threads in CNC machining and general manufacturing.

There are several types of taps used depending on the material and thread requirements:

- Cut taps – These remove metal chips to form threads and are common for softer materials.

- Form taps (roll taps) – Instead of cutting, they push and deform the material to create threads. They work great for ductile metals and improve thread strength.

- Bottoming taps – Designed to cut threads all the way to the bottom of a blind hole, making them perfect for tight spaces where full thread length is needed.

The thread tapping process usually involves aligning the tap with the hole and rotating it to cut the threads. It can be done manually or with CNC machines for higher precision. Thread tapping is ideal for a wide range of applications, from automotive parts to electronics, offering reliable and repeatable threading for medium to high production runs.

What is Thread Milling

Thread milling is a CNC machining process that creates threads by moving a rotating cutting tool in a helical path around a hole. Unlike tapping, which cuts threads by pushing a tap straight into the material, thread milling uses a specialized cutter called a thread mill to carve the threads with precise control.

There are several types of thread mills commonly used:

- Single-point thread mills: These cut the thread profile one point at a time and are versatile for producing different thread sizes with one tool.

- Multi-point thread mills: These have multiple cutting edges, allowing faster thread creation by simultaneously cutting several parts of the thread.

- Full-profile thread mills: These match the thread form exactly and cut the entire profile in one pass for high accuracy.

- Indexable-insert thread mills: These use replaceable inserts, making them cost-effective for long production runs or harder materials.

Thread milling works by interpolating the thread path with the cutting tool, which results in clean, accurate threads. This process is commonly used in applications needing custom threads, hard-to-machine materials, or large threads where tapping might risk breakage. It’s well-suited for precision CNC threading on tough metals, stainless steel, and alloys, especially in aerospace, automotive, and medical part manufacturing.

Key Differences Between Thread Tapping and Thread Milling

When deciding between thread tapping and thread milling, it’s important to understand how they differ in process mechanics, equipment needs, thread size options, and material compatibility.

Process Mechanics Comparison

Thread tapping involves cutting threads by twisting a tap tool directly into a pre-drilled hole. It relies on the tool following a fixed path, removing material to form internal threads. Thread milling, on the other hand, uses a rotating thread mill cutter that moves around the hole in a helical interpolation. This method creates threads by gradually cutting along the surface, allowing more control over thread shape and size.

Equipment Requirements

Thread tapping typically requires a tap tool and a machine capable of spindle rotation with torque control, such as a drill press or CNC machine. Thread milling demands CNC machines with precise multi-axis control to handle the complex tool paths of the thread mill cutter. Thread mills often need more advanced setups but offer greater flexibility.

Thread Size and Type Capabilities

Thread tapping works best for standard thread sizes and is limited by tap tool availability. It’s ideal for smaller to medium-sized threads, especially blind holes. Thread milling can produce a wider variety of thread sizes and types, including custom threads. It also handles larger diameters better and can create threads on through holes and blind holes with equal ease.

Material Compatibility

Thread tapping suits softer to moderately hard materials but risks tap breakage in very hard or tough metals. Thread milling excels in harder materials, like stainless steel or titanium, due to less tool stress and better chip evacuation. This makes thread milling a safer choice for high-strength alloys and tough-to-machine materials.

Understanding these differences helps select the best threading method for your specific job, balancing precision, tool life, and machine capabilities. For more on precision machining and milling options, you can check out HYCNC’s guide on CNC milling part design.

Advantages and Disadvantages

Thread Tapping Advantages and Disadvantages

Advantages:

- Fast and straightforward for creating standard threads, especially in blind holes.

- Lower tool cost compared to thread mills.

- Works well with common materials like aluminum and mild steel.

- Simple setup on most CNC machines without extra programming.

Disadvantages:

- Can cause tool breakage if feed rates or alignment aren’t spot-on.

- Less flexible for custom thread sizes or unusual pitches.

- Not ideal for hard or tough materials as taps wear out quickly.

- Produces more stress and potential chip clogging inside the hole.

Thread Milling Advantages and Disadvantages

Advantages:

- More flexible for custom threads and a wide range of thread sizes.

- Works better with harder materials like stainless steel and titanium.

- Produces cleaner threads with less risk of tool breakage.

- Can be used for internal and external threads as well as multi-start threads.

- Offers better chip evacuation with helical interpolation.

Disadvantages:

- Typically has a higher tool cost and requires advanced CNC programming.

- Takes longer cycle times than tapping in many cases.

- Needs CNC machines capable of helical interpolation and precise control.

Choosing between thread tapping and thread milling depends on your project’s material, thread specs, and production demands. I’m here to help you find the right fit for your needs.

When to Choose Thread Tapping vs Thread Milling

Conditions favoring thread tapping

Thread tapping works best for smaller production runs and standard thread sizes. It’s ideal when you need fast, straightforward threading on materials that aren’t too hard, like aluminum or mild steel. If your project uses through-holes or requires simple internal threads, tapping is usually the go-to. It’s also a good choice when you want to keep tooling costs low and avoid complex setups.

Conditions favoring thread milling

Thread milling shines for tougher jobs and larger or custom thread sizes. It’s perfect when working with hard materials like stainless steel or titanium because it puts less stress on the tool and workpiece. Milling also handles blind holes and offers more flexibility to create special thread forms. If you’re running higher volume parts or need precise control over thread quality, especially on a CNC machine, thread milling is often the better pick.

How HYCNC Optimizes Threading for Your Projects

At HYCNC, we understand that every project has unique threading needs. Our CNC machining and threading capabilities are designed to handle everything from simple thread tapping to complex thread milling. We use state-of-the-art equipment and expert techniques to deliver precision threading that fits your exact specifications.

We offer custom solutions tailored to the material you’re working with—whether it’s aluminum, steel, or exotic alloys—and the type of thread you need. This means we can optimize the process to improve thread quality, tool life, and overall efficiency.

For example, one of our recent projects involved a client needing custom threads in hardened stainless steel. Instead of standard tapping, we used thread milling to reduce tool wear and improve thread accuracy. The result was a perfect fit that boosted their product’s performance and cut down on production time.

With HYCNC, you get expert advice and customized threading solutions that match your production demands and material challenges, making your parts reliable and ready for the tough standards of the U.S. market.

Practical Tips for Choosing the Right Threading Method

Choosing between thread tapping and thread milling depends on several key factors. Here are some practical tips to help you make the right call for your project:

Assess Production Volume Needs

- For high-volume runs, thread tapping is usually faster and more cost-effective.

- Thread milling is better suited for low to medium volumes, especially when flexibility or customization is required.

Consider Material Hardness

- Harder materials like stainless steel or titanium often benefit from thread milling because it reduces tool wear and heat buildup.

- Softer materials like aluminum or brass can work well with thread tapping.

Evaluate Machine Compatibility

- Thread tapping requires machines with rigid tapping capabilities and often a tapping chuck.

- Thread milling needs CNC machines capable of helical interpolation and precise control.

Factor in Tool Costs and Longevity

- Tap tools are generally cheaper but wear out faster and can break in tough applications.

- Thread mill cutters cost more upfront but last longer and can be used on a wider range of materials.

Consult HYCNC Experts

- Our team at HYCNC can analyze your material, thread size, and production needs to recommend the best method.

- We specialize in custom CNC threading solutions tailored to your project’s unique requirements.

For more on optimizing your CNC machining processes, check out our guide on CNC milling part design.

Using these tips can save you time, reduce costs, and improve thread quality on your next project.