What is Milling A Quick Overview

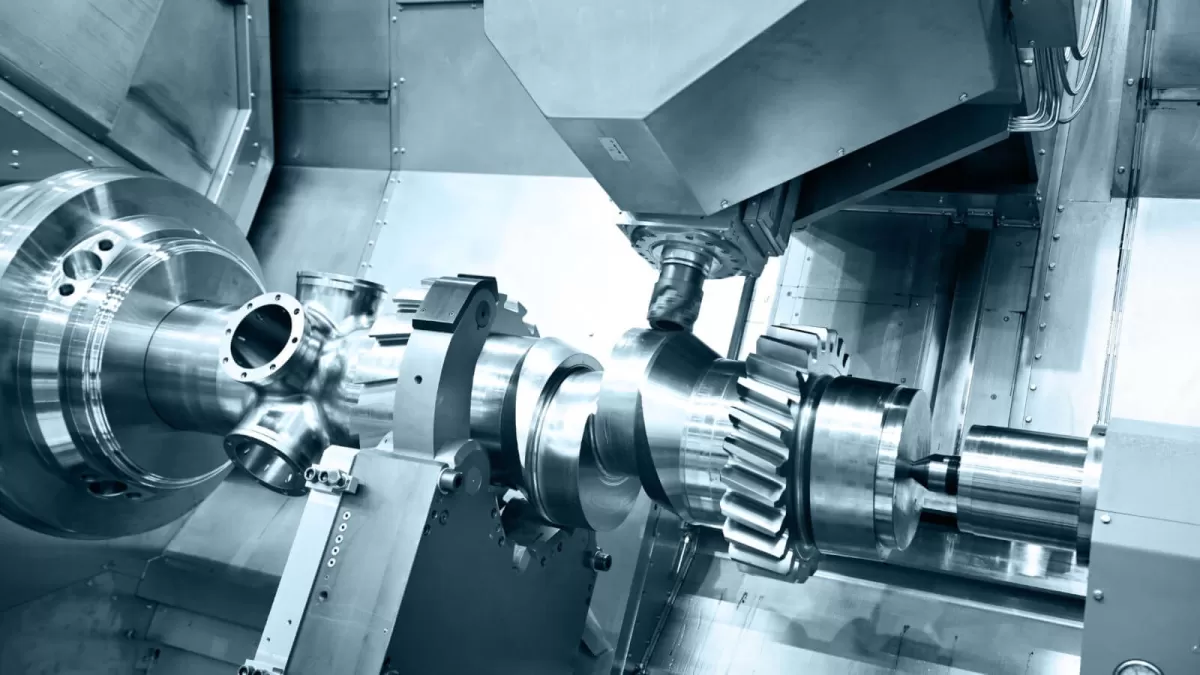

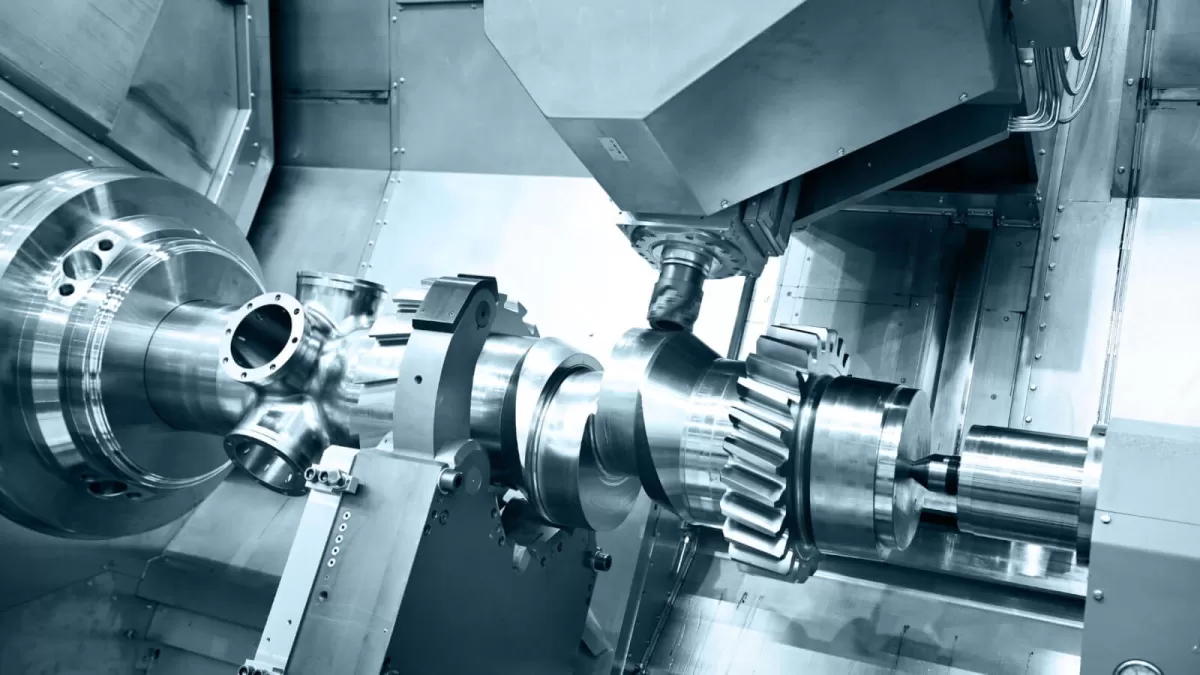

Milling is a fundamental machining process used to remove material from a workpiece by feeding it against a rotating cutting tool. In CNC machining, milling plays a crucial role in shaping precise parts for various industries, from aerospace to automotive. Its ability to create complex geometries and smooth finishes makes it indispensable.

Understanding milling is key when comparing two common techniques: conventional milling and climb milling. These methods differ in how the cutting tool engages with the material, affecting everything from surface finish and tool life to machining efficiency. By grasping the basics of milling, you can better appreciate the strengths and challenges of each approach in CNC applications.

Understanding Conventional Milling Up Milling

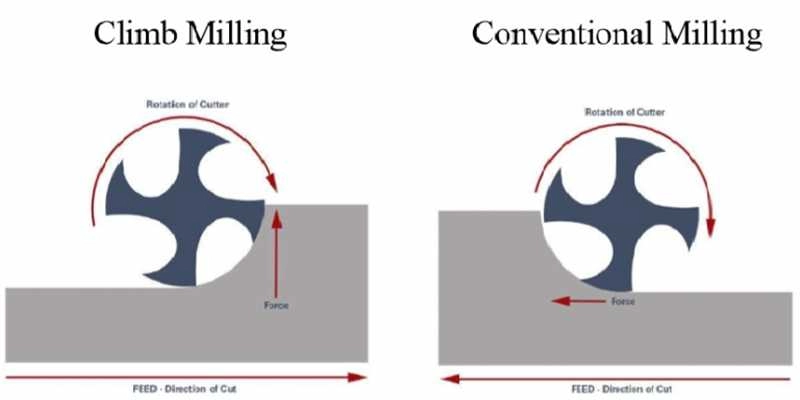

Conventional milling, also known as up milling, is a common CNC milling technique where the cutter rotates against the direction of the feed. In simple terms, the cutter teeth engage the workpiece at the bottom of the cut and move upward, removing material as the feed pushes the workpiece into the tool.

Key Characteristics

- The chip thickness starts at zero and increases as the cutter moves through the material.

- Cutting forces tend to push the workpiece away from the cutter.

- There’s more friction between the tool and the material at the start of each cut.

- Surface finish tends to be rougher compared to climb milling.

Advantages

- Safer for machines with backlash since tool forces tend to pull the workpiece away rather than push it in.

- Better for harder materials or when workpiece fixturing isn’t rock solid.

- Tends to extend tool life by avoiding heavy sudden loads on the cutter.

- Easier to control chip formation, reducing the chance of tool chatter.

Disadvantages

- Higher cutting forces mean more wear on both the tool and machine.

- Surface finish is generally not as smooth as climb milling.

- Can generate more heat due to increased friction, potentially affecting precision.

- Less efficient for high-speed machining because of the way chips form and cut.

Knowing these basics helps when choosing between conventional milling and climb milling for your CNC machining needs.

Understanding Climb Milling Down Milling

Climb milling, also known as down milling, is a CNC milling technique where the cutter rotates in the same direction as the feed of the workpiece. This means the cutting tool engages the material at the thickest part of the chip and gradually cuts down to zero thickness.

Definition and Mechanics

In climb milling, the cutting teeth pull the workpiece into the cutter, creating a downward cutting action. This reduces the cutting forces and prevents the tool from rubbing against the material, resulting in smoother cuts.

Key Characteristics

- Cutter and workpiece move in the same direction

- Chip thickness starts at maximum, tapering to zero

- Better surface finish compared to conventional milling

- Less heat build-up and tool wear

Advantages

- Improved surface finish and accuracy

- Longer tool life due to reduced rubbing

- Lower cutting forces mean less stress on machine components

- Efficient chip evacuation reduces heat

Disadvantages

- Requires machines with minimal backlash to avoid tool damage

- Not ideal for rough or uneven surfaces as the tool can pull the workpiece

- Higher risk of tool grabbing if the workpiece is not securely fixtured

Climb milling is a powerful approach when used with the right equipment and setup, especially for precision CNC machining tasks where efficiency and surface quality matter.

Key Differences Between Conventional and Climb Milling

Understanding the differences between conventional milling and climb milling can help you decide which technique fits your CNC machining needs best. Here’s a quick look at how they compare visually and practically:

| Aspect | Conventional Milling (Up Milling) | Climb Milling (Down Milling) |

|---|---|---|

| Cutting direction | Cutter rotates against feed direction | Cutter rotates with feed direction |

| Chip formation | Thin chip starts, thick chip ends | Thick chip starts, thin chip ends |

| Tool engagement | Gradual engagement | Immediate full engagement |

| Surface finish | Rougher finish, possible rubbing | Smoother finish |

| Cutting forces | Higher and more upward force | Lower and downward force |

| Tool wear | More wear due to rubbing | Less wear, longer tool life |

| Workpiece holding | Less critical | More secure fixturing required |

| Backlash effects | Less sensitive to machine backlash | Can cause issues if backlash is present |

| Heat generation | More heat, can affect tool and material | Less heat generated |

Practical Implications

Conventional milling is often the go-to for machines with backlash issues or when working with harder materials that demand gradual chip formation. It tends to be more forgiving with older or less rigid machines but may cause quicker tool wear and a rougher milling surface.

Climb milling, on the other hand, offers better surface finish and extended tool life, making it ideal for precision CNC machining and softer materials. However, it requires well-maintained machines with minimal backlash and solid workpiece fixturing to prevent tool damage or poor results.

How HYCNC Helps You Choose

At HYCNC, we use our deep experience to match your project goals with the right milling technique. We evaluate your material type, machine condition, and part design to recommend the best approach—sometimes combining both conventional and climb milling to optimize efficiency and quality. Our advanced CNC capabilities mean we can handle the nuances of each method to give you consistent, precise results every time.

If you want to learn more about preparation for milling, check out our guide on CNC milling part design for insights on how part setup affects milling success.

When to Use Conventional Milling

Ideal Scenarios

Conventional milling, also called up milling, works best when dealing with harder materials or worn machines that have backlash issues. It’s the go-to method when you want to avoid sudden tool engagement forces, which helps protect both the tool and the machine. This makes it ideal for:

- Machining tough metals like cast iron or hardened steel

- Situations where the machine or spindle has some backlash or looseness

- Finishing cuts that require better control over chip removal

- Jobs where surface finish isn’t the top priority but tool life and steady cutting are

Case Study

At a midwest manufacturing shop handling cast iron parts, conventional milling was preferred to avoid chatter and minimize tool wear. The shop’s CNC machines had some backlash due to older ball screws, so climb milling caused tool deflections and rough finishes. With conventional milling, they achieved more consistent cuts, longer tool life, and fewer setup issues. This approach kept production steady and helped them meet deadlines without costly tool changes or machine repairs.

When to Use Climb Milling

Climb milling, also known as down milling, is best suited for situations where surface finish and tool life are top priorities. This technique offers smoother cutting action because the cutting tool engages the material at the thickest part of the chip and thins out as it moves. It reduces heat and cutting forces, which helps keep tools sharper longer.

Ideal Scenarios for Climb Milling

- Working with softer materials like aluminum or copper, where minimizing tool wear is important

- When a superior surface finish is required, such as for visible parts or precision components

- CNC machines with minimal backlash and rigid setups that can handle the downward cutting forces

- High-speed machining environments focused on efficiency and accuracy

- Applications where chip evacuation needs to be efficient to prevent recutting chips and workpiece damage

Case Study

At HYCNC, a recent project involved machining aerospace-grade aluminum parts requiring extremely smooth finishes and tight tolerances. Using climb milling, we reduced tool wear by 30% and improved the surface finish beyond client expectations. The rigid CNC machines handled climb milling’s cutting forces well, allowing us to increase feed rates and lower cycle times without sacrificing quality.

If you’re interested in understanding more about part design for efficient CNC milling, check out our detailed guide here.

Factors to Consider When Choosing a Milling Technique

Picking the right milling method—conventional or climb milling—depends on several key factors. Here’s what you need to keep in mind:

Material type

Different materials respond better to certain milling techniques. Harder metals like stainless steel might perform better with conventional milling to reduce tool wear, while softer materials like aluminum often benefit from climb milling for a cleaner finish.

Machine capabilities

Your CNC machine’s rigidity, presence of backlash, and speed range play a big role. Machines with backlash issues usually handle conventional milling better, since climb milling can cause tool pulling and vibration on less rigid equipment.

Project goals

Are you aiming for a smooth surface finish, faster cycle times, or longer tool life? Climb milling generally improves surface finish and reduces cutting forces, but conventional milling can be safer for roughing cuts and minimizing chatter.

Tooling and fixturing

Proper workpiece fixturing and tooling setup is crucial. Climb milling requires robust fixturing to avoid workpiece movement, while conventional milling is a bit more forgiving in this area.

Safety and operator skill

Climb milling can be tricky for less experienced operators because it demands tighter machine control and can exacerbate backlash problems. If safety and control are priorities, conventional milling might be the safer choice.

Making your pick based on these factors helps ensure better CNC machining efficiency, longer tool life, and precise milling surface finish tailored to your specific needs.

Combining Both Techniques for Optimal Results

Hybrid Approach

Using both conventional milling and climb milling in the right way can give you the best of both worlds. This hybrid approach allows you to balance tool life, surface finish, and machining efficiency depending on the stage of your project. For example, you might start with conventional milling to rough out the material safely, then switch to climb milling for finishing to improve surface quality and reduce cutting forces.

HYCNC’s Strategy

At HYCNC, we leverage a tailored mix of conventional and climb milling based on the specific job needs. Our CNC experts analyze your material, machine, and project goals before deciding which technique—or combination—is optimal. This ensures you get precision machining with maximum tool life and minimal downtime. We’re all about making your CNC machining efficient and cost-effective, no matter the complexity.

Tips for Implementation

- Start with conventional milling when dealing with harder materials or older machines prone to backlash.

- Switch to climb milling for finishing passes to get cleaner cuts and better surface finish.

- Ensure your machine setup is solid, with tight fixturing to avoid vibrations or movement during climb milling.

- Monitor tool wear closely and adjust feed rates accordingly to extend tool life.

- Communicate your project priorities (speed, finish, tool cost) so your CNC service provider can craft a plan that fits perfectly.

Using this combined method is smart—it maximizes efficiency and quality while minimizing common milling headaches. If you want to dive deeper into part design strategies that complement your milling techniques, check out our detailed guide on CNC milling part design.

Common Mistakes to Avoid

When working with conventional milling and climb milling, certain pitfalls can mess up your job quality and tool life. Here are some common mistakes to watch out for:

Using climb milling on backlash prone machines

Climb milling pushes the workpiece against the direction of the tool rotation, which can cause the machine’s backlash to grab and jerk the material. If your CNC machine has significant backlash, climb milling might lead to poor surface finish, inaccurate cuts, and even tool damage. Make sure your machine’s backlash is well controlled before opting for climb milling.

Ignoring material properties

Not all materials react the same under up or down milling. Softer materials might handle climb milling better, while harder or brittle ones could chip or crack if the wrong technique is used. Pay attention to the material’s hardness, ductility, and thickness to choose the best milling approach for optimal chip formation and cutting forces.

Inadequate fixturing

Securely holding the workpiece is crucial. Poor fixturing can cause vibration, shifting, or uneven cuts, especially during climb milling where the tool pulls the workpiece toward it. Make sure you use strong, stable fixtures that prevent movement throughout the process to achieve precision machining and protect your tooling.

Avoiding these mistakes helps you get the most from your CNC milling techniques, boosting efficiency, surface finish, and tool life every time.

How HYCNC Can Help

At HYCNC, we bring advanced CNC capabilities to your milling projects, whether you need conventional milling or climb milling. Our state-of-the-art machines are built to handle precise, high-efficiency machining with minimal backlash, ensuring better tool life and superior surface finishes on your parts.

Beyond technology, our expert team guides you through choosing the right milling technique based on your material, machine, and project goals. We understand the practical challenges local businesses face and tailor solutions that improve CNC machining efficiency and reduce costs.

Ready to upgrade your milling process with reliable, professional CNC services? Contact HYCNC today and let us help you get the most out of your milling operations.