Are you torn between SolidWorks and Fusion 360 for your next CNC project? Choosing the right CAD software can transform your design process and boost your manufacturing precision. As a CNC expert, I’ve seen how the right tool can make or break a project. With HYCNC’s cutting-edge machining services, we’ve worked with both platforms to deliver flawless results. In this guide, you’ll uncover the key differences, features, and costs of SolidWorks vs Fusion 360, plus insider tips on which aligns best with your CNC machining needs. Let’s jump in and find your perfect fit!

Overview of SolidWorks and Fusion 360

When choosing the right CAD software for CNC machining and design, many ask: How do SolidWorks and Fusion 360 compare? Both are powerful tools, but they serve different needs and industries.

SolidWorks

SolidWorks has been a staple in the CAD world since the mid-1990s. It’s known for its robust parametric modeling, detailed engineering features, and strong integration with manufacturing workflows. SolidWorks is best suited for professional engineers, large manufacturers, and firms focused on complex product design, especially where precision and detailed documentation are critical.

Key strengths include:

- Advanced parametric design and assembly capabilities

- Extensive simulation and validation tools

- Strong compliance with industry standards

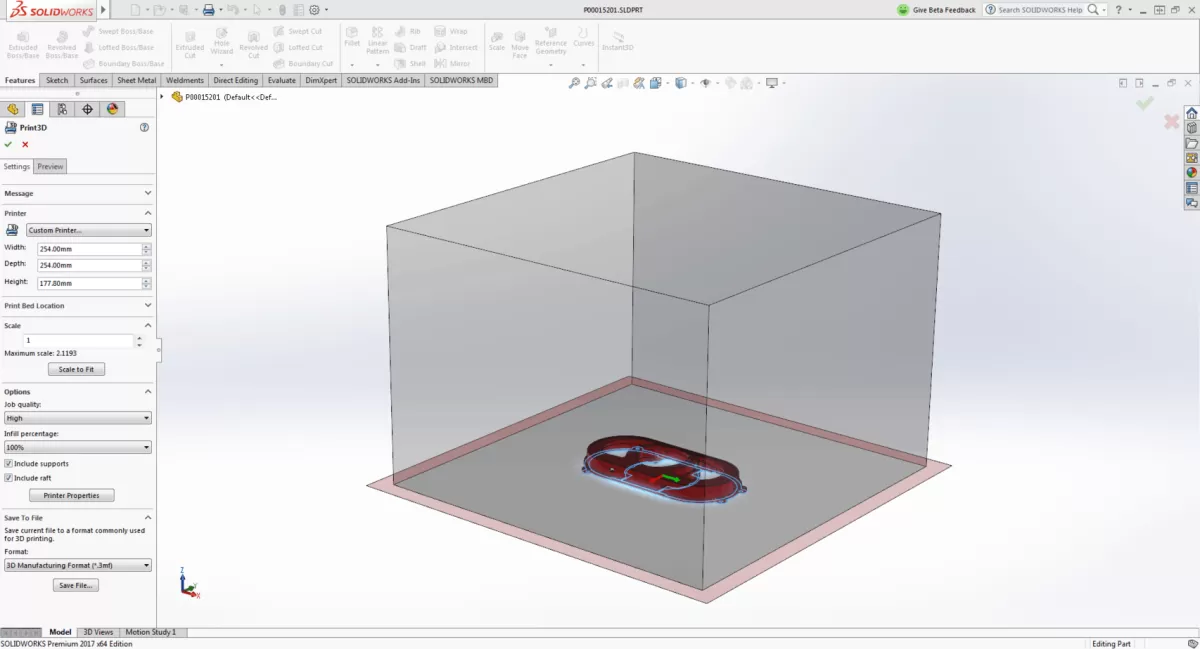

For CNC machining, SolidWorks excels in creating detailed, manufacturable designs but often requires third-party add-ons or CAM software to generate toolpaths. At HYCNC, we see many professionals using SolidWorks for high-precision parts before moving to dedicated CAM platforms.

Fusion 360

Autodesk introduced Fusion 360 in 2013 with a modern, cloud-based approach. It combines CAD, CAM, and CAE in one platform, making it popular among hobbyists, startups, and small businesses. Fusion 360’s user-friendly interface and integrated CAM tools make it particularly attractive for CNC machine shops looking for an all-in-one solution.

Key strengths include:

- Intuitive freeform modeling with T-Splines

- Built-in CAM for CNC toolpath generation

- Cloud-based collaboration and easy access

For HYCNC and similar CNC services, Fusion 360 offers seamless integration from design to machining. Its combined CAD/CAM workflow reduces setup time and streamlines communication between designers and CNC operators.

CNC Machining and HYCNC Integration

Both software options support CNC machining workflows, but with different approaches:

- SolidWorks is highly reliable for detailed mechanical designs but typically relies on external CAM tools for CNC programming.

- Fusion 360 offers an all-in-one CAD/CAM solution, simplifying the path from design to machining—ideal for quick prototyping and small-batch runs.

At HYCNC, our experience shows clients benefit from choosing the software that best fits their scale and workflow. Professionals with complex engineering needs often prefer SolidWorks, while startups and hobbyists thrive with Fusion 360’s integrated system and affordable access.

Feature Comparison

3D Modeling and Design

SolidWorks shines with its parametric modeling and advanced surfacing tools, making it a top pick for detailed, precise engineering designs. You can control every dimension and feature, which is ideal for professional-grade parts and assemblies. Its interface is built for precision, which is why manufacturing firms prefer it.

On the other hand, Fusion 360 offers a more intuitive freeform modeling approach with T-Splines technology. This lets you create smooth, organic shapes quickly, great for startups, hobbyists, and small businesses that want flexibility and speed. Fusion blends parametric and direct modeling for a simpler design process.

Simulation and Analysis

For simulation, SolidWorks delivers extensive Finite Element Analysis (FEA) capabilities, including thermal and fluid dynamics. This makes it powerful for testing how products perform under real-world conditions.

Fusion 360 provides basic simulation functions—enough for early testing but not as deep as SolidWorks. It covers stress, thermal, and modal analyses but isn’t built for heavy-duty engineering simulation.

CAM Integration

CNC machining users should note the difference in CAM support. SolidWorks requires third-party add-ons or separate CAM software to generate CNC toolpaths. This can mean extra cost and steps in your workflow.

Fusion 360 stands out with built-in CAM tools, letting you design and create CNC toolpaths in one platform. This tight integration saves time and suits CNC shops and small manufacturers.

Collaboration and Cloud Features

SolidWorks mainly runs as a desktop application but offers cloud-based options and Product Data Management (PDM) for sharing and version control. However, these require extra licenses and setup.

Fusion 360 is fully cloud-based, providing real-time collaboration from any device. Teams can work together instantly, making it a better fit for remote work or small teams needing quick feedback loops.

Rendering and Visualization

Both platforms offer good rendering tools, but Fusion 360’s cloud rendering is faster and easier to access, while SolidWorks delivers high-quality photorealistic visuals with more control, favored in marketing and detailed presentations.

This breakdown helps CNC users, especially those working with HYCNC, decide which software aligns better with their workflow—whether they need powerful parametric design and simulation in SolidWorks or the all-in-one, user-friendly CAM tools of Fusion 360.

Pricing and Accessibility

When it comes to SolidWorks pricing, it’s generally on the higher end. SolidWorks uses a licensing model that includes a hefty upfront cost plus annual maintenance fees. You’ll often hear about its Standard, Professional, and Premium packages, each adding more advanced features. This makes it a solid choice for larger businesses or manufacturing firms with the budget to invest. SolidWorks offers trial versions, but they’re typically time-limited and require more powerful computer specs, usually Windows-based systems.

On the other hand, Fusion 360 pricing is more flexible and budget-friendly, especially for small businesses, startups, and hobbyists. It offers multiple tiers, including a free version for personal use and startups making less than $100,000 annually. Paid plans are subscription-based, which means no big upfront costs and the option to pay monthly or yearly. Fusion 360 also supports Windows and Mac, plus it’s cloud-based, so you can access it from different devices easily. There’s a free trial for the paid tiers too, which helps users explore full capabilities before committing.

For CNC users, here’s the bottom line in terms of cost-benefit:

- SolidWorks is a good investment for professional shops needing advanced features, especially for intricate designs that require detailed engineering. Licensing costs can add up but deliver robust parametric modeling and compatible export options.

- Fusion 360 gives great value with its built-in CAM tools, making it easier and cheaper to integrate CNC machining workflows without additional software. It’s perfect if you want a streamlined solution that covers design, simulation, and machining under one roof.

If you want to learn more about exporting designs from these platforms, check out this guide on exporting to DXF from SolidWorks and this helpful article on 4 ways to export a DXF from Fusion 360.

Usability and Learning Curve

SolidWorks has a steeper learning curve, making it better suited for experienced users, especially engineers and designers who need advanced features. It takes time to master its full capabilities, but the payoff is powerful control over complex projects.

Fusion 360, on the other hand, is much more intuitive and beginner-friendly. Its clean interface and guided workflows help new users get up to speed quickly, which is great if you’re just starting out or running a small business.

Both platforms offer plenty of training resources. SolidWorks has extensive official tutorials, technical documentation, and a large professional community. Fusion 360 provides solid online guides, forums, and regular updates, with strong community support through Autodesk’s cloud platform.

For most U.S. users, especially those looking to quickly dive into CAD and CNC without a heavy upfront time investment, Fusion 360’s easier learning curve is a big advantage. But if you’re aiming for professional-level design work and don’t mind the time it takes to learn, SolidWorks is more powerful in the long run.

Industry Use Cases and CNC Integration

SolidWorks is a staple in large manufacturers and engineering firms across the U.S. Its strength lies in handling complex, detailed assemblies that meet strict compliance and industry standards. Big companies rely on SolidWorks for precision, durability, and advanced testing before parts hit the production floor. It’s also popular where product lifecycle management (PLM) and regulatory documentation are essential.

On the other hand, Fusion 360 shines with hobbyists, startups, and small businesses. Its cloud-based setup and integrated CAM tools make it ideal for quick prototyping, custom designs, and smaller batch production. Fusion 360’s ease of use lets less experienced users jump into CNC machining without a heavy upfront tool investment.

When it comes to HYCNC, both platforms fit well but in different ways. SolidWorks users typically engage HYCNC for large-scale, high-precision jobs where compliance and tight tolerances matter. Fusion 360 clients often benefit from streamlined workflows with HYCNC’s CNC services because of the built-in CAM and smooth cloud collaboration. Overall, HYCNC optimizes each software’s output, helping you get your CNC parts faster and with confidence, whether you’re a big enterprise or a startup.

Pros and Cons of SolidWorks vs Fusion 360 from HYCNC Perspective

SolidWorks Pros and Cons

Pros

- Powerful parametric design tools for complex parts

- Great for large assemblies and detailed projects

- Strong simulation and analysis capabilities

- Industry-standard in professional engineering and manufacturing

- Extensive third-party add-ons and integration

Cons

- High upfront cost and ongoing license fees

- Steep learning curve, especially for beginners

- Limited collaboration without extra cloud modules

- CAM features require additional purchases

Fusion 360 Pros and Cons

Pros

- Affordable with free tiers for startups and hobbyists

- Fully cloud-based with real-time collaboration

- Built-in CAM tools perfect for CNC machining

- User-friendly and easier to learn

- Supports multiple platforms (Windows and Mac)

Cons

- Less powerful simulation tools compared to SolidWorks

- May struggle with very large assemblies or highly detailed models

- Some advanced features limited to paid tiers

- Cloud dependency can be a downside without reliable internet

HYCNC Perspective on CNC Service Suitability

- SolidWorks fits well with professional CNC operations that demand precise engineering, complex simulations, and large-scale manufacturing workflows. It’s ideal if you already use or plan to scale large projects requiring full ecosystem support.

- Fusion 360 is highly recommended for small businesses, startups, and hobbyists focused on CNC machining. Its built-in CAM and cloud features simplify CNC integration, making it easier to prepare files for HYCNC services.

- Overall, Fusion 360 offers the best balance of cost, usability, and CNC readiness for most users working with HYCNC, but SolidWorks remains the top choice for heavy-duty professional environments.

Which Software Should You Choose

Choosing between SolidWorks and Fusion 360 comes down to your specific needs, experience level, and budget—especially if you’re working with HYCNC for CNC machining services.

Criteria for Choosing SolidWorks

- You’re a professional engineer or part of a large manufacturing firm.

- You need advanced parametric modeling, detailed simulation options, and complex assembly management.

- You require industry-standard CAD tools with strong compliance support.

- Your projects involve heavy-duty CNC machining that might need deep integration with third-party CAM add-ons.

- You have a bigger budget and prefer a more traditional desktop software setup.

Criteria for Choosing Fusion 360

- You’re a hobbyist, startup, or small business looking for an affordable, all-in-one CAD/CAM solution.

- You want easy-to-learn software with built-in CAM tools for CNC—you don’t want to juggle multiple platforms.

- Cloud collaboration and version control are important, especially if you work remotely or with a small team.

- Your designs are mostly for 3D printing, CNC prototyping, or product development on a smaller scale.

- You prefer subscription pricing or want access to a free tier to start.

HYCNC Recommendation on Software and Service Alignment

At HYCNC, we see Fusion 360 as the go-to for most small to medium CNC projects due to its seamless CAM integration and cloud-based workflow. It makes sending files for CNC machining straightforward and efficient. However, if you’re handling large-scale manufacturing, complex assemblies, or need deep simulation — SolidWorks aligns better with those demands.

Bottom line, if you’re just getting started or need flexibility, Fusion 360 fits the bill. For professional-grade engineering and heavy CNC work, SolidWorks remains the top choice. Either way, HYCNC supports both workflows to make your CNC project smooth and precise.

FAQs

What are the main differences between SolidWorks and Fusion 360?

SolidWorks is a powerful, professional-grade CAD software favored by large manufacturers and engineering firms. It excels in parametric modeling, advanced simulation, and detailed assembly management but comes with a steeper learning curve. Fusion 360 is more user-friendly, cloud-based, and offers integrated CAM tools, making it ideal for startups, hobbyists, and small businesses focusing on quick iterations and collaboration.

Are both programs compatible with HYCNC CNC services?

Yes, both SolidWorks and Fusion 360 work well with HYCNC services. SolidWorks files like STEP and DXF formats are widely supported, and exporting files for CNC from SolidWorks is straightforward. Fusion 360’s built-in CAM and easy export options like DXF (4 ways to export from Fusion 360) also integrate smoothly with HYCNC machining workflows.

Is the Fusion 360 free version suitable for professional projects?

Fusion 360’s free version is great for hobbyists and small startups but has limitations on commercial use and some advanced features. For full professional capabilities, especially in CNC machining and large-scale product development, upgrading to a paid plan is recommended.

How do these software handle large assemblies?

SolidWorks shines here with robust tools designed for big, complex assemblies often needed in manufacturing and engineering sectors. Fusion 360 can manage assemblies but may struggle with very large or intricate projects compared to SolidWorks.

Which software is better for 3D printing and CNC machining?

Both are solid choices, but your pick depends on your needs:

- SolidWorks: Best for detailed parametric designs and engineering precision. Great if your workflows involve complex assemblies and need deep simulation before manufacturing.

- Fusion 360: Stands out with built-in CAM, easy cloud collaboration, and flexibility for rapid prototyping and CNC machining. Better suited if you value simplicity and integrated tools without additional add-ons.

Choosing between them comes down to your project scale, budget, and whether you prioritize advanced engineering features or streamlined, all-in-one workflows. For more on file preparation from SolidWorks for CNC, you can also check this guide on converting to sheet metal tools.