Understanding DXF Export in Fusion 360

What Is Fusion 360

Fusion 360 is a powerful cloud-based CAD, CAM, and CAE tool used by engineers, designers, and makers. It combines 3D modeling, simulation, and manufacturing features in one platform. With its intuitive interface and wide-ranging capabilities, Fusion 360 is popular for creating precise designs ready for CNC machining, laser cutting, and other manufacturing processes.

Common Use Cases for DXF Export

DXF (Drawing Exchange Format) files are essential when you want to transfer 2D geometry to different manufacturing workflows. In Fusion 360, exporting DXF files is common for:

- CNC machining where toolpaths require precise 2D outlines

- Laser cutting and engraving projects that rely on vector paths

- Sheet metal flat patterns that need unfolding before fabrication

- Sharing drawings with other CAD or CAM software for collaboration

DXF export helps bridge the gap between design and manufacturing, making your design ready for real-world production.

Key Considerations Before Exporting

Before exporting a DXF from Fusion 360, keep these points in mind to ensure a smooth manufacturing process:

- Check your geometry: Simplify or clean sketches to avoid unwanted lines or overlaps.

- Confirm units: Make sure Fusion 360’s units match your CNC or laser cutter requirements (inches vs millimeters).

- Define the correct plane: DXF files are 2D, so export from the right sketch or flat pattern view.

- Avoid unnecessary objects: Hide or remove construction lines and annotations to keep the DXF clean.

- Consider the purpose: Choose the export method that matches your workflow, whether it’s sketch-based for quick outlines or flat patterns for sheet metal work.

Understanding these basics sets you up for success when preparing DXF files from Fusion 360 for CNC machining and laser cutting.

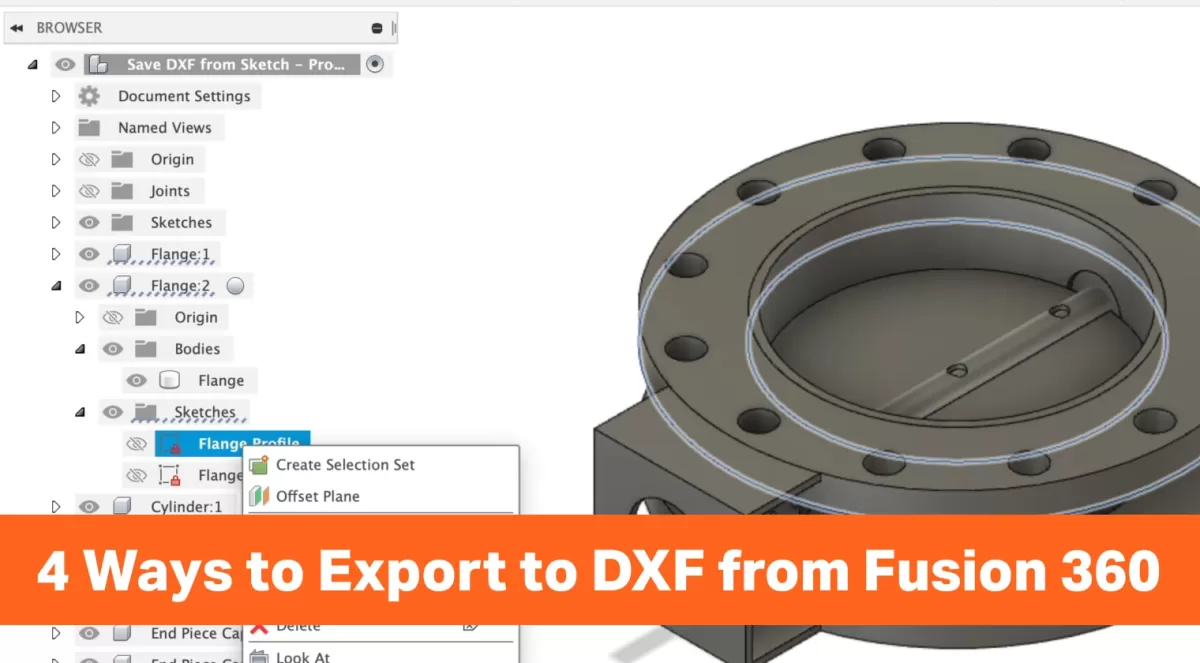

Method 1 Exporting from a Sketch

Overview

Exporting a DXF from a sketch in Fusion 360 is one of the most straightforward ways to get your 2D profiles ready for CNC machining or laser cutting. This method works best when your design starts as a sketch and you want to directly export those lines, arcs, and shapes without extra features or 3D elements. It’s perfect for simple parts, laser cutting, or CNC services like HYCNC.

Step by Step Process

- Open your Fusion 360 design and go to the Sketch workspace.

- Select the sketch you want to export from the browser on the left.

- Right-click the sketch name and choose Save as DXF.

- A dialog box appears; choose the folder and file name you want, then save.

- The DXF file is now ready to be used for CNC machining or laser cutting.

Pros and Cons

Pros:

- Simple and quick export process.

- Clean 2D geometry ideal for CNC and laser cutting.

- No need to create a drawing or flat pattern first.

Cons:

- Only exports the sketch plane; 3D features or sheet metal bends won’t export.

- If your sketch has overlapping or hidden geometry, it might complicate the DXF.

HYCNC Tip

Before exporting, double-check your sketch for any overlapping lines or small gaps. HYCNC recommends clean, closed profiles for the best CNC or laser cutting results. Also, make sure your units match the machine settings to avoid scaling issues during cutting.

Using this sketch export method is a great first step for anyone working with 2D designs in Fusion 360, especially if you plan on sending your files to a CNC service like HYCNC.

Method 2 Exporting from Flat Pattern Mode Sheet Metal

Overview

If you’re working with sheet metal parts in Fusion 360, exporting your design as a DXF from the Flat Pattern mode is a great option. This method lets you get a 2D flat layout of your sheet metal, perfect for CNC machining DXF files or laser cutting Fusion 360 designs. It captures bend lines and cutouts accurately, making it ideal for manufacturing.

Step by Step Process

- Open your sheet metal design in Fusion 360.

- Switch to the Sheet Metal workspace.

- Click on Create Flat Pattern to generate the unfolded version of your part.

- Right-click the flat pattern in the browser tree.

- Select Save as DXF from the context menu.

- Choose your destination folder and save the file.

- Double-check your DXF in a viewer or CAM software before sending it to HYCNC for machining.

Pros and Cons

Pros:

- Accurate flattening of complex bends.

- Includes bend lines, which are critical for sheet metal fabrication.

- Clean, ready-to-use geometry for CNC services.

Cons:

- Only works with sheet metal parts, not regular solid models.

- Complex flat patterns might still need minor cleanup before machining.

- Doesn’t work if the flat pattern isn’t created beforehand.

HYCNC Tip

Before exporting, make sure your flat pattern is fully updated and reflects any recent design changes. HYCNC recommends keeping bend reliefs and corner treatments simple to avoid issues during CNC cutting or bending. Always verify your units (inches or millimeters) to match your machining requirements directly in Fusion 360.

Method 3 Exporting from a 2D Drawing Not Recommended

Overview

Exporting a DXF from a 2D drawing in Fusion 360 sounds logical but is usually not the best way. Drawings are built mainly for documentation, not for CNC or laser cutting. They can add unwanted layers or extra details that complicate the DXF file.

Step by Step Process

- Open your Fusion 360 project and create a 2D drawing from your design.

- Arrange the view as needed on the sheet.

- Go to the File menu and select Export.

- Choose DXF as the file type.

- Save the file to your computer.

Pros and Cons

Pros:

- Easy for generating flat views of parts.

- Good for sharing detailed drawings with people not using Fusion 360.

Cons:

- May include annotations, dimensions, and extra line types you don’t want in your CNC or laser cut file.

- The complexity can cause issues when importing into HYCNC or other CNC services.

- Less control compared to exporting directly from sketches or flat patterns.

HYCNC Tip

Avoid using 2D drawings for DXF export if you’re planning to send your files to HYCNC for CNC machining. Instead, export directly from a sketch or flat pattern to get a clean, simplified DXF file that cuts down on errors and processing delays.

Method 4 Exporting from File Menu Not Recommended

Overview

You can export a DXF file in Fusion 360 directly from the File menu by saving your design as a DXF format. While it sounds simple, this method often creates issues like extra or missing geometry, making it less reliable for precise CNC machining or laser cutting jobs. This option is easy but not the best choice if you want clean DXF files for HYCNC services.

Step by Step Process

- Open your design in Fusion 360.

- Click File > Export.

- In the export window, select DXF as the file type.

- Choose where to save your file.

- Click Export to complete the process.

Pros and Cons

| Pros | Cons |

|---|---|

| Simple and quick to perform | Often includes unwanted geometry |

| No need to prepare sketches | Can miss critical details needed for CNC |

| Works directly from any model | Limited control over units and layers |

HYCNC Tip

If you use this method, always open your DXF in a CAD viewer before sending it to HYCNC. Check for unnecessary lines or missing features. For better results, export DXFs from sketches or flat patterns instead—they’ll be cleaner and ready for CNC machining or laser cutting right away.

Best Practices for DXF Export with HYCNC

When exporting your DXF files from Fusion 360 for HYCNC’s CNC services, following these best practices ensures smooth processing and accurate results.

Verify Geometry

Before exporting, clean up your sketch or flat pattern. Make sure all lines are connected and closed where needed. Unjoined or overlapping lines can cause errors in CNC machining DXF files. Double-check that your design matches exactly what you want to cut or machine.

Ensure Correct Units

Set your units properly in Fusion 360 before exporting. Whether inches or millimeters, consistency prevents sizing problems during laser cutting or CNC work. HYCNC requires files in the correct unit system, so double-check your Fusion 360 CAD export settings to avoid costly mistakes.

Avoid Common Pitfalls

- Remove unnecessary dimensions, notes, or construction lines from your sketch or drawing before export.

- Don’t include text or bend lines unless you coordinate with HYCNC, as these might not translate well in DXF for manufacturing.

- Always review the exported DXF in a viewer to catch any unexpected geometry.

Prepare for HYCNC’s CNC Services

- Communicate your material and thickness clearly with HYCNC along with your DXF.

- If you’re unsure about your file, ask HYCNC for advice—they can guide you on file prep specifics for laser cutting or CNC machining.

- Use flat pattern DXF exports whenever dealing with sheet metal parts for best compatibility.

Following these tips will help you get the most out of Fusion 360 DXF export for HYCNC’s services, saving time and avoiding rework.

FAQs

Can I export DXF files from the free version of Fusion 360?

Yes, you can export DXF files using the free Fusion 360 version. However, some advanced export features might be limited compared to the paid version. Exporting from sketches or flat patterns remains fully accessible.

Why does my DXF include unwanted geometry?

Unwanted lines or shapes often come from overlapping sketch elements or hidden construction lines. Double-check your sketch before exporting and delete any unnecessary or construction geometry to keep your DXF clean.

How do I ensure my DXF is compatible with HYCNC’s CNC services?

Verify that your geometry is closed and continuous.

Use the correct units (usually inches or millimeters).

Remove construction and annotation lines.

Simplify your paths to avoid CNC toolpath issues.

If you follow these steps, your DXF will be ready for CNC machining at HYCNC.

What if my design includes text or bend lines?

Text and bend lines can cause problems with CNC tools if not handled correctly. For text, convert it to outlines or curves before exporting. For sheet metal bend lines, confirm they are marked properly in the flat pattern export. Providing clear instructions to HYCNC will help us process your design smoothly.

For more tips on exporting CAD files, check out our guides on exporting from AutoCAD and exporting from Autodesk Inventor.