Understanding Composite Materials

What Are Composite Materials

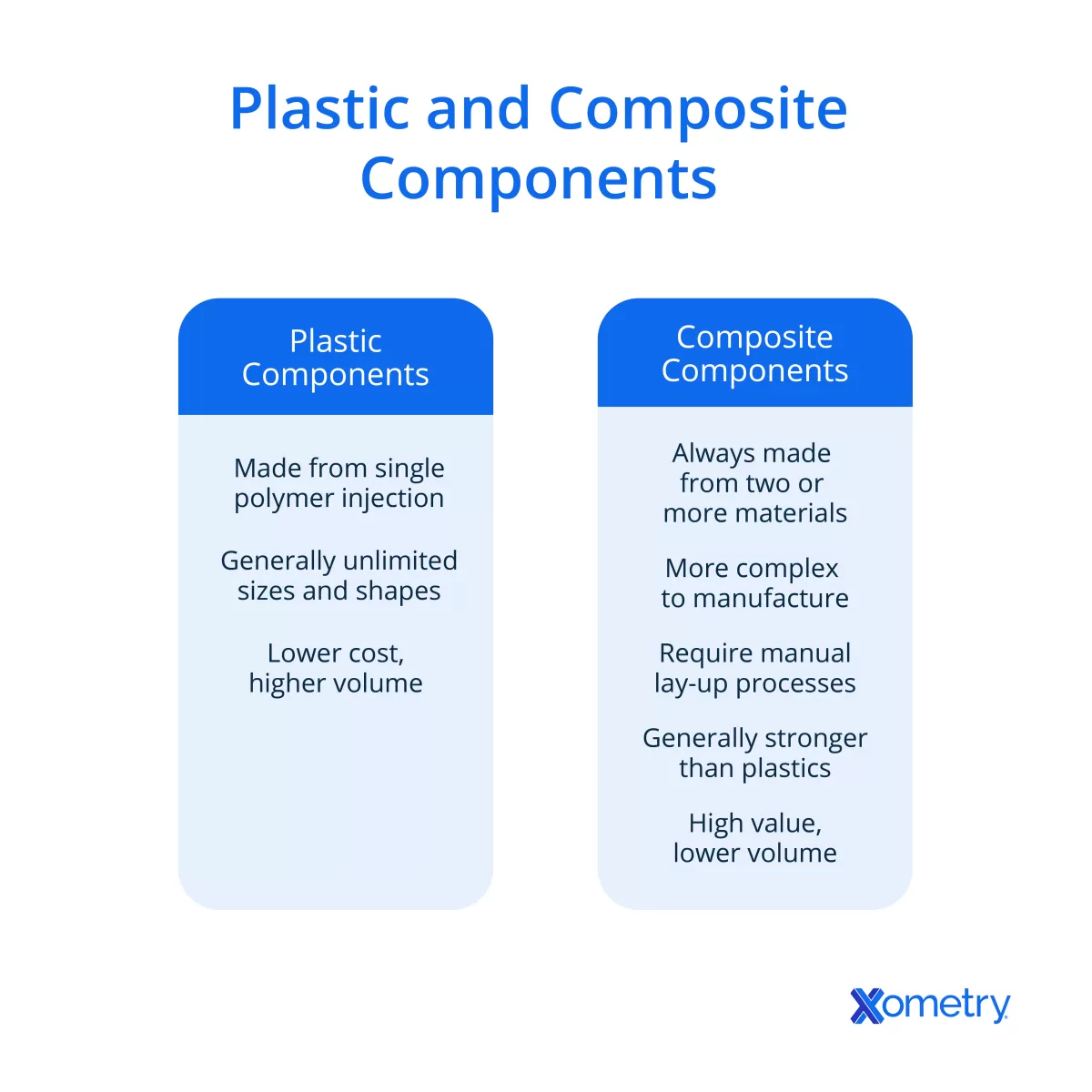

Composite materials are engineered substances made by combining two or more distinct materials to create a product with enhanced properties. Typically, these consist of a reinforcement (such as fibers) embedded within a matrix (a binding material like resin). This combination results in a material that often outperforms its individual components in strength, durability, and weight.

Common reinforcements include carbon fiber, glass fiber, and aramid (like Kevlar), while matrices are usually polymers, metals, or ceramics. The synergy between the fiber and matrix determines the overall performance of a composite.

Key Properties to Consider

When selecting the right composite material, understanding key properties is essential:

-

Strength and Stiffness

How much load the composite can bear without deformation or failure.

-

Weight

Lightweight composites like carbon fiber offer excellent strength-to-weight ratios, ideal for aerospace and automotive parts.

-

Durability and Fatigue Resistance

Resistance to wear, environmental conditions, and repeated stress.

-

Thermal Stability

Ability to maintain performance under varying temperatures, critical for applications involving heat.

-

Impact Resistance

The material’s capacity to absorb shocks and resist fracture.

-

Chemical Resistance

Important for exposure to solvents, fuels, or corrosive environments.

-

Manufacturing Compatibility

How well the composite suits your production methods, including CNC machining, molding, or additive manufacturing.

Understanding these fundamental aspects helps guide the composite material selection process to fit your specific project needs efficiently and effectively.

Step-by-Step Guide to Selecting the Right Composite Material

Picking the right composite material can feel tricky, but breaking it down step-by-step makes it manageable. Here’s how I’d approach it:

Step 1 Define Project Requirements

Start by clearly outlining what your project needs. Think about:

- Strength and weight targets

- Environmental conditions (heat, moisture, UV exposure)

- Durability and lifespan expectations

- Any special performance needs like impact resistance or flexibility

Step 2 Evaluate Fiber and Matrix Options

Next, look at the materials that make up your composite:

- Fibers: Carbon fiber, fiberglass, Kevlar, or hybrids—all offer different strengths and stiffness

- Matrix: The resin or polymer holding fibers together affects toughness and heat resistance

Choosing the right fiber and matrix combo is key to hitting those project requirements.

Step 3 Assess Manufacturing Compatibility

Make sure the composite you choose works with your manufacturing method. If you’re using CNC machining composites or molding, the material has to fit the process without causing issues like excessive wear or defects.

Step 4 Analyze Cost vs Performance Trade-offs

Check your budget against what you need performance-wise. Sometimes high-performance materials like carbon fiber bring great results but push costs up. Fiberglass or hybrids can offer more cost-effective options if budget is tight without giving up too much on quality.

Step 5 Prototype and Test

Before full-scale production, build prototypes and test them. This helps confirm your selection holds up in the real world and lets you make adjustments early. Using composite prototyping and tools like finite element analysis (FEA) can speed this step up and reduce risk.

Following these steps will guide you to the best composite material selection for your project needs and keep production smooth and on budget.

Common Composite Materials and Their Applications

When choosing the right composite material, it helps to know the popular types and where they work best.

Carbon Fiber Reinforced Polymer CFRP

CFRP is known for its high strength-to-weight ratio and stiffness. It’s widely used in aerospace, automotive, and sporting goods where lightweight performance is key. Carbon fiber properties like excellent fatigue resistance and low thermal expansion make it ideal for high-performance parts.

Glass Fiber Reinforced Polymer GFRP

GFRP is more affordable than carbon fiber and still offers good strength and corrosion resistance. You’ll often find it in marine, construction, and wind energy applications. It’s a solid choice if you want cost-effective composite materials without sacrificing durability.

Aramid Kevlar Twaron

Aramid fibers like Kevlar and Twaron are famous for impact resistance and toughness. These composites are commonly used in body armor, protective gear, and aerospace components where energy absorption matters most. Kevlar applications focus heavily on safety and durability.

Hybrid Composites

Hybrid composites combine two or more fiber types, like carbon and glass, to balance strength, weight, and cost. These materials can be tailored for specific needs, offering versatility for industries like automotive and sporting equipment.

For more details on composite materials and CNC machining composites, check out our composites material page to see various options and their machining compatibility.

Tools and Resources for Material Selection

Picking the right composite material gets easier when you use the right tools and resources. Here’s what I recommend for a smooth selection process:

Material Databases

These online databases give you quick access to detailed info about various composite material properties. You can compare stiffness, strength, durability, and even cost data for materials like carbon fiber, fiberglass, and Kevlar. Some popular ones include MatWeb and Granta Design. Using these helps narrow down options before you dive deeper.

Simulation Software

Simulation tools like Finite Element Analysis (FEA) software are a game changer. They let you model how a composite will perform under real-world conditions like stress or heat. This is huge if you’re working with CNC machining composites or need to understand composite material behavior without expensive prototypes.

Consulting Experts

Don’t skip talking to specialists. Material scientists, engineers, and suppliers can provide insights tailored to your specific project, helping you avoid common mistakes. Their practical knowledge about matrix and reinforcement combinations or cost-effective composite materials can save you time and money.

Using a mix of these resources puts you in a strong position to select the best composite material for your needs.

Common Mistakes to Avoid

Choosing the right composite material can be tricky, and some common mistakes can cost you time and money. Here’s what to watch out for:

Ignoring project requirements

Skipping a clear understanding of what your project needs—whether it’s strength, weight, or durability—often leads to picking the wrong composite.

Overlooking manufacturing limitations

Not considering how your chosen composite works with your manufacturing process, especially if you use CNC machining, can cause delays and extra expenses.

Focusing only on cost

Choosing the cheapest material without weighing performance can result in failures or more expensive fixes down the road.

Neglecting fiber and matrix compatibility

The bond between fiber and matrix is key. Overlooking this can reduce strength and durability.

Skipping prototyping and testing

Assuming a material will perform perfectly without a trial run is risky. Always prototype and test thoroughly before full production.

Ignoring available tools and expert advice

Not using material databases, simulation software like Finite Element Analysis, or consulting with experts means missing out on valuable insights.

Avoiding these common pitfalls will help you make the best composite material selection for your project, saving you headaches and improving results.