What Is Preflighting and Why It Matters for CNC Machining

You might be wondering, what exactly is preflighting, and why is it so important for CNC machining? Preflighting is the process of checking your design files before sending them off to production. It helps catch common issues like incorrect units, missing or stray points, overlapping lines, and dimension errors that could cause costly delays or scrap parts.

At HYCNC, we’ve seen how careful preflighting can save time and money by reducing errors that might otherwise require remaking parts. Our guidelines emphasize the importance of clean, accurate files to ensure smooth CNC machining and faster turnaround times. Taking just a little extra time to preflight your designs means fewer headaches and lower costs down the road.

Setting Up QCAD for Effective Preflighting

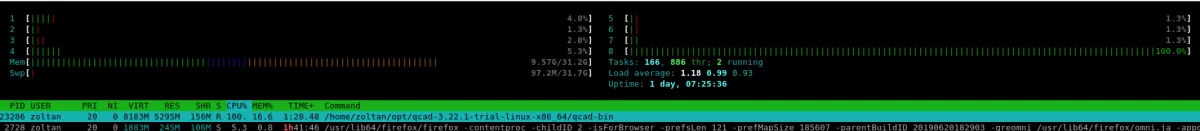

To start preflighting your designs using QCAD, you first need to download and install the software. Head over to the official QCAD website and get the latest version compatible with your Windows or Mac system. Installation is quick and straightforward—just follow the prompts.

Once installed, setting up your workspace and units is crucial for accurate CNC design preparation. Open QCAD and configure the drawing units to match your project needs—whether inches or millimeters. This step ensures your DXF or DWG files align with the real-world measurements required for machining.

Adjusting your workspace to a clean, simple layout helps reduce errors when reviewing or editing. Customize toolbars and grids for easier navigation, making it simple to spot any issues during your QCAD preflighting checks.

By setting up QCAD right from the start, you save time and avoid costly mistakes down the line when prepping files for CNC machining or laser cutting.

Step by Step Guide to Preflighting Your Designs in QCAD

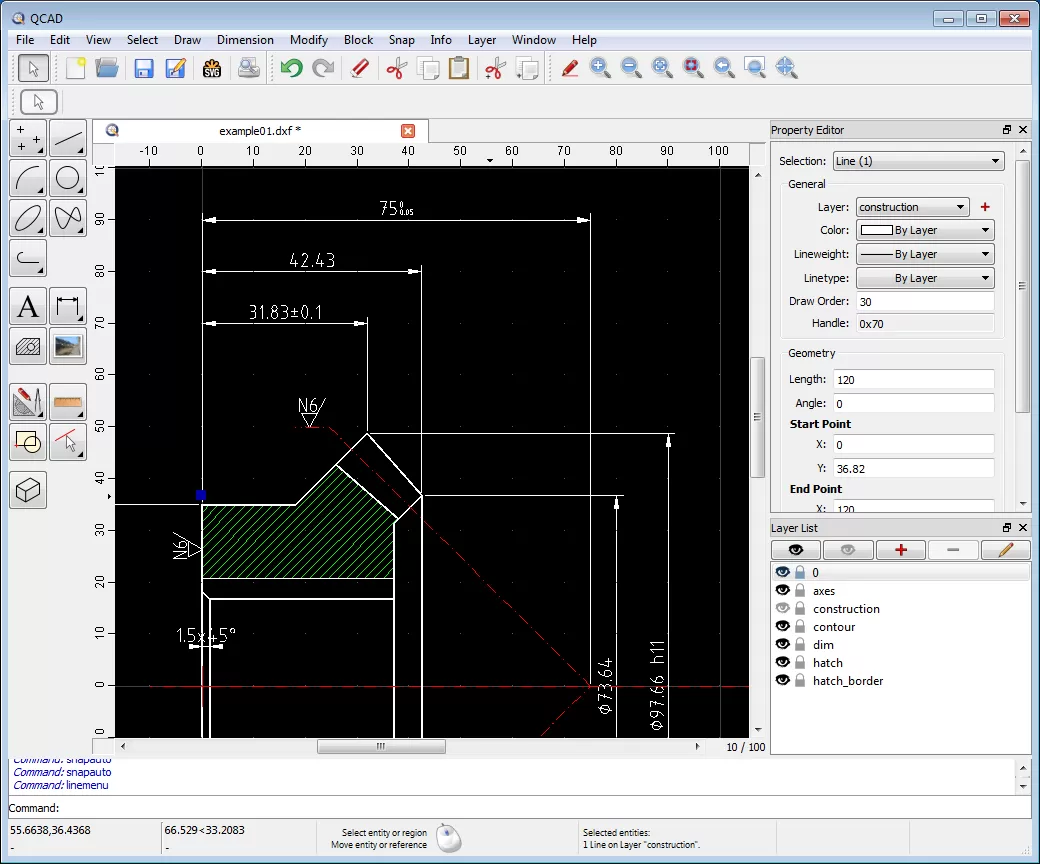

Starting with your design file, open your DXF or DWG in QCAD. This lets you see everything clearly before you start checking for issues.

Next, check your units and dimensions. Make sure your drawing is set to the right measurement system—whether inches or millimeters—to match your CNC machining needs. This step prevents costly mistakes later.

Then, look for common errors. These include stray points, overlapping lines, or shapes that aren’t closed. QCAD makes it simple to spot and fix these problems so your design is clean and ready.

After this, verify your design specs. Double-check details like hole sizes, cutouts, and overall dimensions against your project requirements. This ensures your design will fit and function as expected.

Finally, save your work and export the file in the preferred format. Usually, DXF is the go-to for CNC services like HYCNC because it’s widely supported and accurate.

Following these steps helps you prepare your CAD files properly, making the CNC machining process smooth and efficient.

Advanced Tips for Optimizing QCAD Designs for HYCNC

To get the most out of your QCAD designs when working with HYCNC, there are some smart tricks you can use to streamline the process and avoid common mistakes.

-

Use Draft Mode to Simplify Drawings

Draft Mode in QCAD reduces the file complexity by hiding unnecessary details. This makes your design cleaner and faster to process, helping prevent errors during CNC machining.

-

Leverage the Sheet Metal Bending Calculator

If your project involves sheet metal, QCAD’s Sheet Metal Bending Calculator is a lifesaver. It helps you calculate accurate bend allowances and avoid costly mistakes like over-bending or incorrect angles. For more on sheet metal prep, check out our guide on design for manufacturing and assembly for easier sheet metal fabrication.

-

Test Complex Designs with the Instant Quoting Tool

Before finalizing your design, use HYCNC’s instant quoting tool to test how your file will be priced and processed. This can help you spot costly design features or unnecessary complexity early and make adjustments to save on manufacturing costs.

-

Avoid Common Design Pitfalls

- Watch out for stray points and tiny line segments that can confuse CNC machines. Use QCAD’s tools to clean up these bits.

- Double-check your layers and line types – make sure they match what HYCNC expects.

- Confirm all units and dimensions are consistent throughout your design to avoid scale issues.

By applying these tips, your QCAD files will be optimized not just for accuracy but also for efficiency and cost savings with HYCNC’s CNC machining services.

How HYCNC Ensures Your Preflighted Designs Shine

At HYCNC, we know that even the best preflighted designs need a final check before machining. That’s why we offer a thorough file review process focused on the types of files you create in QCAD, like DXF and DWG. Our team carefully inspects your design for any overlooked errors, ensuring everything meets the specs for smooth CNC machining.

We support all standard QCAD files and make it easy for you to upload your preflighted designs directly to our platform. This streamlines the process and saves you time.

Once your file is approved, we guarantee fast turnaround times so your parts can be made and shipped quickly without delays. Ready to get started? Upload your QCAD preflighted design now and see how HYCNC makes CNC design preparation simple and reliable.