Introduction to Laser Cutting

Wondering what laser cutting is and why it’s become such a big deal? Simply put, laser cutting is a high-precision CNC process that uses a focused laser beam to cut or engrave materials. Think of it as a super-accurate, computer-controlled blade made of light that can slice through everything from metal to wood.

So why is laser cutting so popular? It comes down to three key benefits:

- Precision – It delivers clean, detailed cuts that other methods struggle with.

- Versatility – Works on a wide range of materials, from fabrics to metals.

- Efficiency – Perfect for fast manufacturing and prototyping with minimal waste.

Laser cutting isn’t just for big factories. It’s a game changer for many industries like automotive, aerospace, and medical, as well as hobbyists and craftspeople who demand detailed and customizable work. Whether you’re creating auto parts or custom signs, laser cutting is a reliable and widely used technology.

How Does Laser Cutting Work

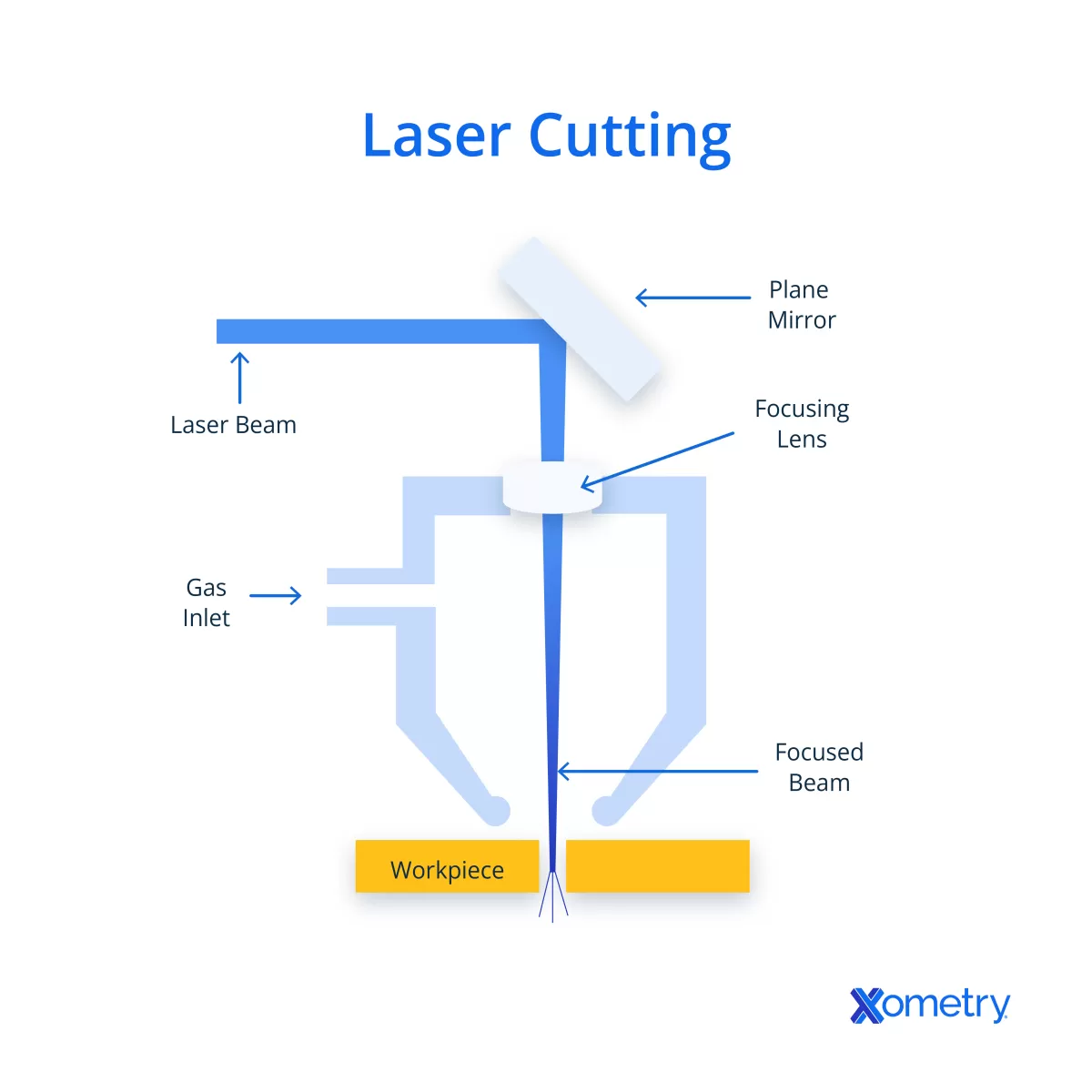

Laser cutting uses a focused laser beam to melt, burn, or vaporize materials following a precise, programmed path. This path is controlled by CNC (Computer Numerical Control), which ensures every cut matches the design exactly. The CNC system drives the movement of the cutting head with pinpoint accuracy.

Key parts involved in the process include:

- Laser resonator: generates the laser beam

- Mirrors and lenses: direct and focus the beam onto the material

- Cutting head: houses the laser and usually a nozzle that delivers assist gases

- XY gantry: moves the cutting head horizontally over the workpiece

Together, these components work seamlessly to produce clean, accurate cuts. For a clearer understanding, a simple diagram showing the laser beam path controlled by the CNC over the material can be very helpful.

Types of Laser Cutting Technologies

There are several types of laser cutting technologies, each suited for different materials and applications.

-

CO2 Lasers

These are common and cost-effective. They work great for cutting non-metal materials like wood, acrylic, textiles, leather, and some plastics. CO2 lasers deliver clean cuts and are widely used in crafts and signage.

-

Fiber Lasers

Fiber lasers offer high precision and are perfect for metals such as stainless steel, aluminum, brass, and titanium. They cut faster and with better accuracy on metals than CO2 lasers, making them popular in automotive and aerospace industries.

-

Nd:YAG Crystal Lasers

Known for their high power, these lasers are ideal for thicker and tougher materials. They’re often used for industrial metal cutting, especially where more intense laser energy is needed for hard metals.

-

Special Techniques

Beyond standard cutting, there are advanced laser methods like stealth dicing used in semiconductor manufacturing, reactive cutting that uses oxygen for faster metal cutting, and oxygen-assisted vector cutting for intricate designs. These techniques allow even more detailed and precise work in high-tech industries.

Each type of laser serves a unique purpose depending on the material and the desired level of detail, making laser cutting a versatile tool across multiple fields.

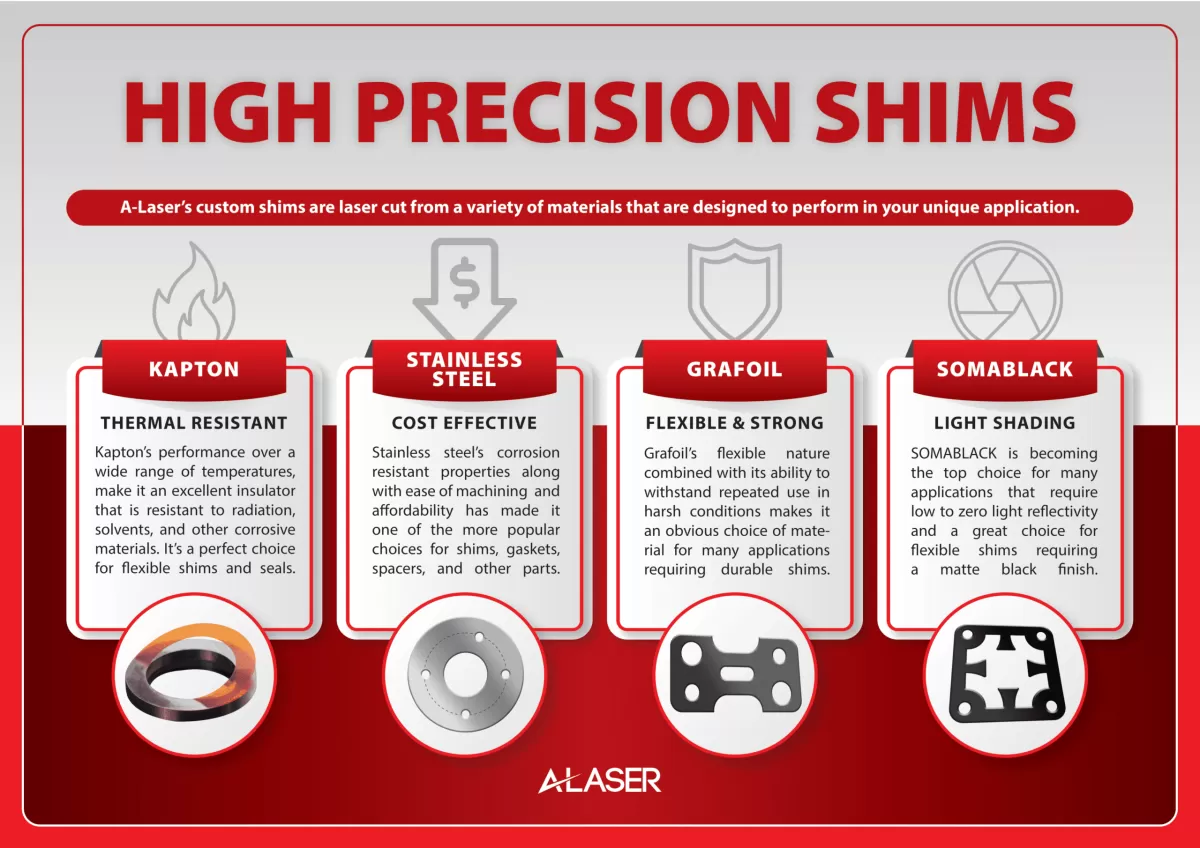

Materials Suitable for Laser Cutting

Laser cutting works well with a wide range of materials, making it a versatile option for many projects. Here’s a quick look at what you can cut:

Metals

- Steel (including stainless steel)

- Aluminum

- Brass

- Titanium

Non-Metals

- Wood

- Acrylic

- Leather

- Fabrics

- Foam

- Paper

Limitations to Keep in Mind

Some materials can be tricky for laser cutting:

- Reflective metals like copper and some aluminum grades can reflect the laser, requiring specialized fiber lasers or adjustments.

- Thick materials (typically over 10mm) may need more powerful lasers or alternative cutting methods.

- Certain plastics might release fumes, needing proper ventilation during cutting.

Recommended Laser Types by Material

| Material | Best Laser Type | Common Applications |

|---|---|---|

| Steel | Fiber Laser | Industrial parts, automotive |

| Aluminum | Fiber Laser | Aerospace components, signage |

| Wood | CO2 Laser | Crafts, furniture, decorative |

| Acrylic | CO2 Laser | Displays, signage, art pieces |

| Leather | CO2 Laser | Fashion accessories, upholstery |

| Fabrics | CO2 Laser | Custom apparel, textiles |

| Foam | CO2 Laser | Packaging, inserts |

| Paper | CO2 Laser | Invitations, models |

For metals like steel and aluminum, you can find more details on laser cutting on our laser cut steel and laser cut aluminum pages.

Understanding the right material and laser pairing helps achieve the best quality and efficiency in your projects.

Applications of Laser Cutting Across Industries

Laser cutting is widely used across many industries in the U.S. because of its precision and flexibility. Here’s a quick look at where it makes a difference:

- Automotive: Creating precise body panels and small components that fit perfectly into vehicles.

- Aerospace: Producing lightweight, intricate parts for airframes to meet strict safety and performance standards.

- Medical: Manufacturing surgical instruments and implants with tight tolerances and clean edges.

- Textile and Fashion: Cutting detailed fabric patterns and custom designs without fraying.

- Consumer Goods: Personalizing items like jewelry, coasters, and signs with crisp, intricate cuts.

At HYCNC, we specialize in serving U.S.-based industries by providing fast, reliable CNC laser cutting services tailored to your specific manufacturing needs. Whether you need prototyping or small-to-medium production runs, our local expertise ensures quality and quick turnaround.

Benefits of Laser Cutting

Laser cutting offers high precision and accuracy, making it ideal for complex designs that require fine details. It reduces material waste thanks to its clean, narrow cuts, which helps save on costs and resources. This process is versatile, working well across a wide range of materials and industries—from metals to fabrics and more.

For small to medium production runs, laser cutting is a cost-effective choice because it doesn’t require expensive tooling or long setup times. Plus, when cutting fabrics, the laser seals the edges as it cuts, which helps prevent fraying and keeps your products looking sharp and durable.

Limitations of Laser Cutting

Laser cutting comes with some downsides you should know about. First, the equipment costs can be high upfront, plus ongoing maintenance isn’t cheap either. Running these machines uses a fair amount of energy, which adds to operational expenses.

Another limitation is material thickness. Most lasers work best with materials under 10mm thick, so cutting thicker metals or materials might need special types of lasers or different methods.

Safety is also a concern. Cutting certain plastics or materials can release fumes that require proper ventilation and safety measures to protect workers and the environment.

Knowing these limits helps you decide when laser cutting is the right choice for your project or when another process might be better.

Why Choose HYCNC for Laser Cutting Services

At HYCNC, we specialize in CNC laser cutting with years of hands-on experience serving industries across the United States. We understand the importance of precision, speed, and quality when it comes to your projects, whether it’s for automotive parts, aerospace components, or custom consumer goods.

Choosing a local provider like HYCNC means faster turnaround times and direct communication, ensuring your specifications are met without delays. We maintain strict quality controls and use the latest laser cutting technology to deliver clean, accurate cuts every time. Plus, working with us gives you the advantage of personalized service tailored to your specific needs.

Ready to see how HYCNC can help with your next laser cutting project? Contact us today for custom laser cutting solutions or request a free quote. Let’s bring your ideas to life efficiently and reliably.

Future Trends in Laser Cutting

Laser cutting technology is evolving fast, and several key advancements are shaping its future. We’re seeing the rise of ultrafast lasers, which offer even higher precision and speed. These lasers reduce heat damage and allow for cleaner cuts on delicate materials. Alongside that, AI-driven automation is improving the accuracy and efficiency of CNC laser cutting machines, making it easier to handle complex designs with minimal human input. Hybrid systems that combine laser cutting with other methods, like milling or waterjet, are also becoming more common, giving manufacturers more flexibility.

Sustainability is a big focus too. New laser cutting systems are designed to be more energy-efficient, cutting down on power use and reducing waste. This helps companies meet growing environmental standards while keeping costs in check.

The market for laser cutting is projected to grow significantly, reaching around $6 billion by 2030, according to Digital Journal. With these innovations and a strong push for greener practices, laser cutting will remain a vital tool for industries across the US, from automotive to medical devices.

For those curious about the economics behind laser cutting equipment, check out our post on the true cost of owning a laser cutter. It offers a clear picture of what to expect when investing in these advanced tools.