What Are Tolerances in Manufacturing

In manufacturing, tolerance refers to the permissible limit of variation in a physical dimension or measured value. It defines how much a part’s actual size can deviate from its nominal dimension, or ideal design size, and still function correctly. Tolerances are critical because even the smallest deviations can affect how parts fit together, perform, and maintain reliability—especially in industries where precision matters, such as aerospace, automotive, and medical devices.

Take, for example, a CNC-machined aircraft component that requires extremely tight tolerances, often within ±0.01 millimeters. Such precision ensures that parts assemble perfectly without the risk of failure or increased wear over time. Achieving these tight tolerances demands not only state-of-the-art machining equipment but also a deep understanding of material behavior and careful process control.

At HYCNC, we specialize in delivering parts that meet these exacting standards. Our advanced CNC machining capabilities, combined with rigorous tolerance analysis and quality checks, allow us to consistently produce components that adhere to tight tolerance requirements. By partnering closely with clients throughout the design and manufacturing process, we help ensure parts fit and function exactly as intended, minimizing rework and maximizing performance.

Key Concepts of Tolerance Fundamentals

Understanding tolerance starts with the nominal dimension, which is the ideal size specified in a design. Think of it as the perfect target measurement for a part. However, in real-world manufacturing, parts won’t always match this size exactly. That leads us to the tolerance range, which defines how much a part’s actual size can deviate from the nominal dimension while still being acceptable.

When you’re dealing with assemblies made of multiple parts, tolerance stack-up becomes important. This is the accumulation of small deviations from each part adding up, potentially impacting the fit and function of the final assembly. Managing this stack-up is critical for avoiding problems like loose fits or interference.

To communicate these requirements clearly, the industry relies on standards like GD&T (Geometric Dimensioning and Tolerancing). Standards such as ASME Y14.5 and ISO 8015 provide a consistent language for specifying and inspecting tolerances, reducing confusion between design and manufacturing teams.

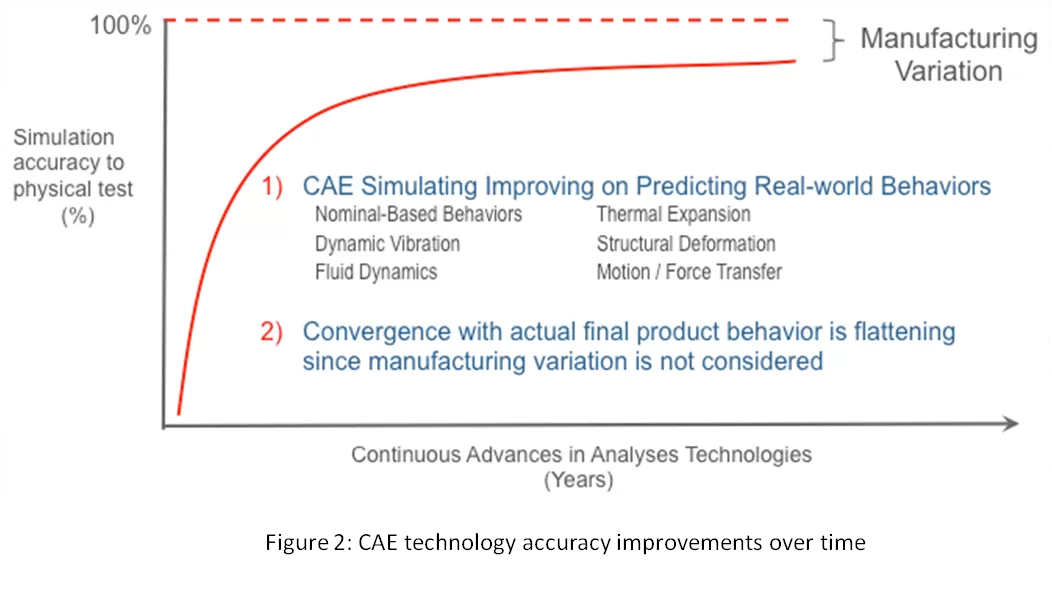

When analyzing tolerances, there are two main approaches: worst-case tolerance analysis assumes all parts are at their maximum allowed deviation at the same time, ensuring guaranteed assembly but often leading to tighter—and sometimes costly—controls. On the other hand, statistical tolerance analysis uses realistic probability methods like Root Sum Square (RSS) or Monte Carlo simulations to estimate how variations actually stack up, often allowing for looser, more cost-effective tolerances without compromising quality. For example, in a multi-part assembly, worst-case analysis might call for extremely tight tolerances, but statistical methods show that the chance of failures is negligible with slightly wider limits.

Why Tolerance Analysis Matters

Tolerance analysis is critical for making sure parts fit and work together as intended. Without proper analysis, even small deviations can cause assembly issues or part failures, leading to costly reworks or scrapped components.

Balancing precision with manufacturing cost is another key benefit. Tight tolerances usually mean higher costs, so tolerance analysis helps find the sweet spot—ensuring parts are accurate enough without unnecessary expense.

It also boosts overall quality and reliability by reducing the chance of defects. When tolerances are well managed, products perform better and last longer, which builds trust and lowers warranty claims.

For example, HYCNC recently optimized an automotive part by carefully analyzing the tolerance stack-up. This improved the part’s fit and function while cutting production costs by minimizing wasted material and time spent on adjustments. This real-world case highlights why tolerance analysis is a must in precision manufacturing.

Methods of Tolerance Analysis

When it comes to tolerance analysis, there are a few key methods we rely on to make sure parts fit and function perfectly.

Worst-case analysis is the most straightforward. It considers the maximum possible variation for each part and ensures that even in the worst scenario, the assembly will still work. This method guarantees a solid fit but can be conservative, sometimes leading to tighter—and more expensive—manufacturing requirements.

On the other hand, statistical analysis offers a smarter way to balance quality and cost. We use techniques like Root Sum Square (RSS), which calculates the combined effect of individual tolerances assuming they vary randomly. Another powerful method is the Monte Carlo simulation, which runs thousands of virtual assembly scenarios to predict how parts might fit in real life. This gives a more realistic view of tolerances and helps avoid over-tightening specs.

Tolerance stacks can be simple or complex depending on the design.

- 1D tolerance stacks look at variations along a single dimension, great for simple parts.

- 2D tolerance stacks consider two dimensions, often used for flat surfaces or features on a plane.

- 3D tolerance stacks take into account all three dimensions, essential for complex assemblies where parts move or fit into each other in multiple directions.

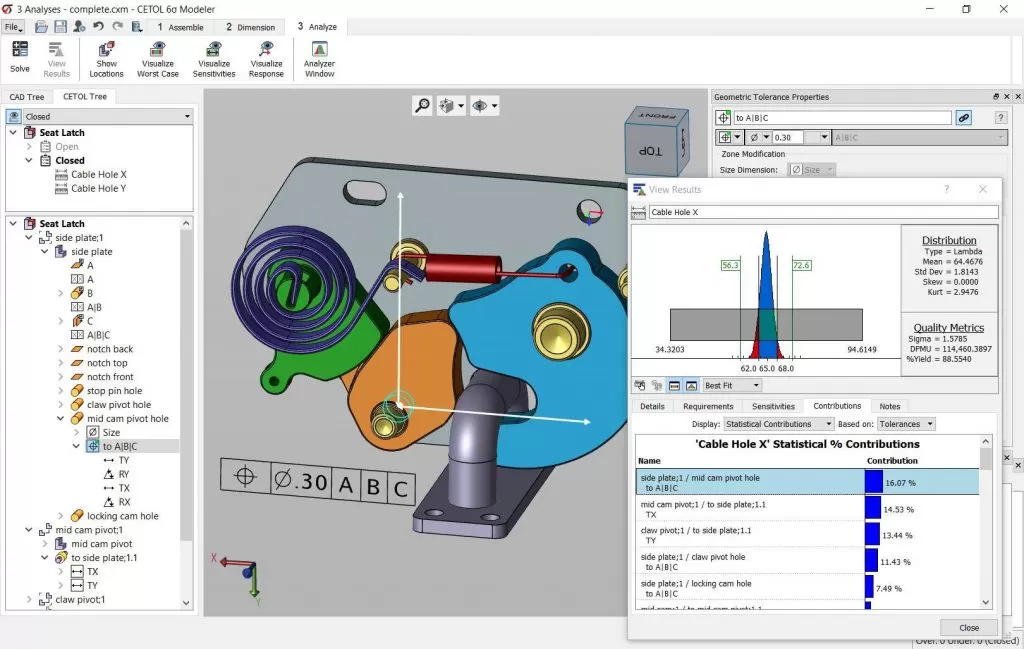

At HYCNC, we integrate advanced tools and software to make this process precise and efficient. Programs like Creo EZ help us build tolerance stack-ups quickly, while 3DCS software enables detailed 3D tolerance simulation and analysis. These tools help us catch potential issues early and optimize tolerances to keep your project on time and within budget.

Practical Steps to Apply Tolerance Fundamentals

Applying tolerance fundamentals starts with setting clear standards that match ASME, ISO, and your specific client requirements. This ensures everyone is on the same page regarding allowable dimensional variation and quality expectations.

Next, create a tolerance stack-up by mapping out how individual part tolerances add up in the final assembly. You can use simple spreadsheets for smaller projects or specialized software for more complex designs. This helps identify where tight tolerances are necessary and where there’s room to relax them.

Once you have your stack-up, adjust and optimize tolerances to find the right balance between precision and manufacturability. Overly tight tolerances can drive up cost and production time, so aim for enough accuracy to ensure function without unnecessary expense.

At HYCNC, we work closely with clients during the design phase to review and refine tolerances early on. This collaboration helps avoid miscommunication and ensures the parts we manufacture meet functional needs while keeping costs efficient.

Common Challenges and How to Overcome Them

One of the biggest hurdles in tolerance fundamentals is setting tolerances too tight. When tolerances are narrower than needed, manufacturing costs can skyrocket without real benefits. It’s crucial to find the right balance so parts function well without unnecessary expense.

Another frequent issue is miscommunication between design and manufacturing teams. Designers may specify tolerances that are hard to achieve or don’t consider production realities. This disconnect often leads to rework, delays, and frustration.

Environmental factors also get overlooked sometimes. Changes in temperature, material expansion, or even humidity can affect dimensional variation. Ignoring these can cause parts to misfit or fail during use.

Here’s how we tackle these challenges at HYCNC:

- We use GD&T standards to clearly define tolerances, ensuring everyone – from design to shop floor – is on the same page.

- We involve our manufacturing experts early in the design phase to recommend realistic tolerance ranges that maintain quality while controlling cost.

- Our team accounts for environmental conditions during analysis and machining to prevent surprises later on.

By applying these solutions, we help clients avoid costly mistakes, improve communication, and deliver reliable parts every time.

Tolerance Fundamentals in CNC Machining

Precision tolerances are key in CNC machining because many industries demand exact parts that fit and function perfectly. Small dimensional variations can lead to big problems, especially in fields like aerospace, automotive, and medical devices.

At HYCNC, we focus on maintaining ultra-tight tolerances, often as precise as ±0.005 mm. This level of accuracy ensures that parts meet the highest quality standards and perform reliably in their final application.

For example, we’ve successfully achieved a ±0.01 mm tolerance on a medical device component. This precision is critical to patient safety and device performance, showing how mastering tolerance fundamentals in CNC machining can make all the difference.

Best Practices for Tolerance Management

Managing tolerances effectively starts early—right in the design phase. Defining tolerance requirements upfront helps avoid costly changes later and ensures all team members are on the same page. Always follow established standards like ASME Y14.5 or ISO 8015. These guidelines provide a clear, common language for specifying tolerances, reducing miscommunication between design and manufacturing.

Working closely with your CNC service provider, such as HYCNC, is crucial. We help align design intent with production capabilities, making sure the tolerances you need are achievable and practical. This collaboration minimizes surprises during manufacturing and improves part quality.

Before full production, don’t skip prototype testing. Validating your tolerances with real parts helps catch potential issues early, allowing you to fine-tune dimensions and avoid expensive rework down the line. Following these best practices leads to better quality, cost control, and smoother project delivery.