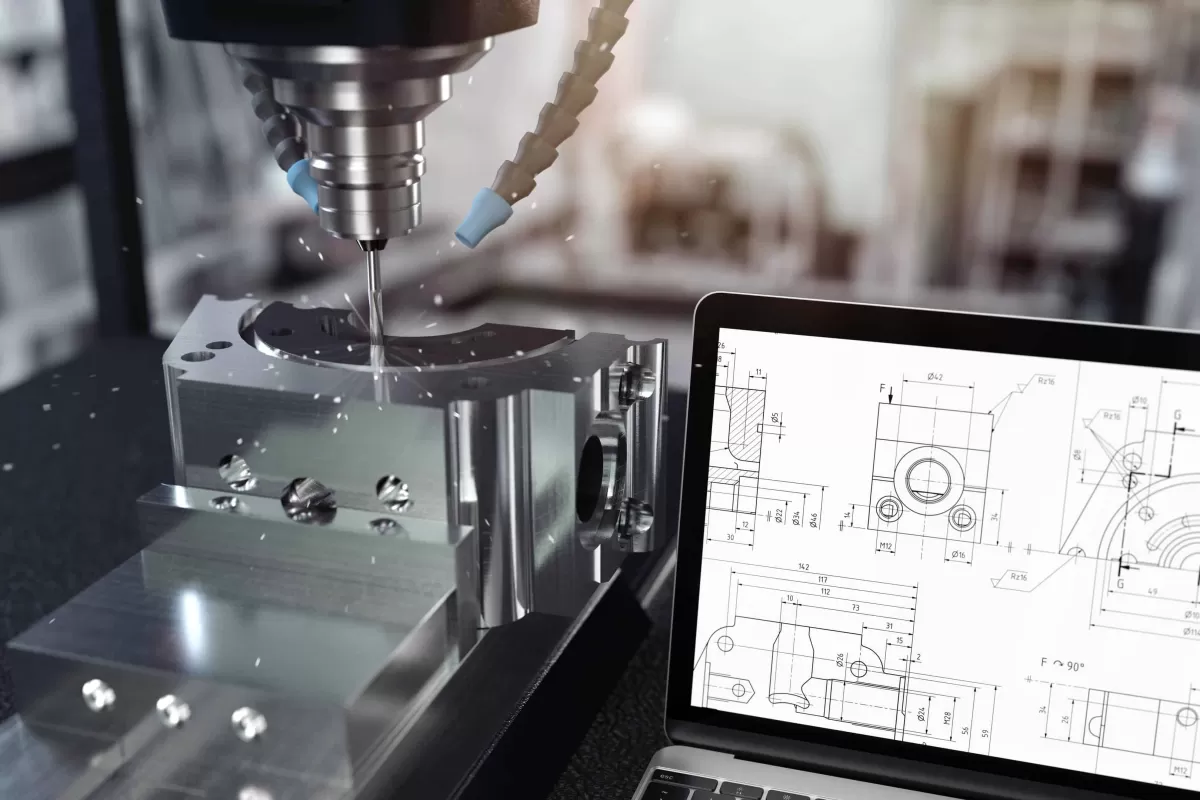

Struggling to make sense of engineering drawings for your next project? These critical blueprints are the backbone of precision manufacturing, guiding CNC machines to create parts with pinpoint accuracy. As a designer, engineer, or business owner, mastering technical drawings can unlock seamless collaboration with manufacturers like HYCNC. In this guide, you’ll discover what engineering drawings are, their role in CNC machining, and practical tips to ensure your designs come to life flawlessly. Let’s dive in and demystify the process!

What Are Engineering Drawings

Definition and Purpose

Engineering drawings, also known as technical drawings or engineering blueprints, are detailed visual representations used to communicate how a mechanical part or assembly should be made and assembled. These drawings serve as the universal language in manufacturing and engineering, providing clear instructions that guide the entire production process. Whether you’re designing a complex machine or a simple part, engineering drawings ensure everyone—from engineers to machinists—understands the exact specifications needed.

Key Components of an Engineering Drawing

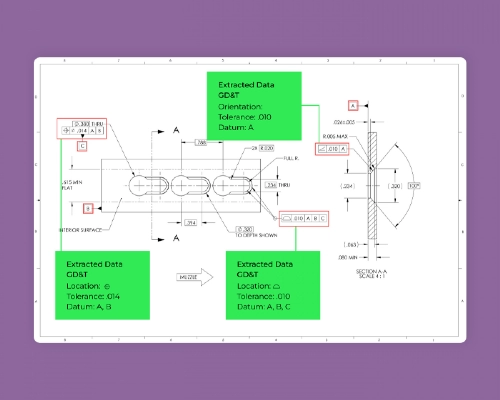

A well-crafted engineering drawing includes several critical elements to convey its message accurately:

- Views: Multiple angles such as front, top, side, and sectional views to fully depict the object.

- Dimensions: Precise measurements like lengths, diameters, and tolerances that dictate size and fit.

- Notes: Additional instructions or material specifications.

- Symbols: Standardized marks indicating finishes, welding, or machining processes.

- Title Block: Contains project details like part name, drawing number, scale, and author.

These components work together to create a complete and unambiguous guide for manufacturing.

Types of Engineering Drawings

There are several types you might encounter in CNC machining and mechanical design:

- Detail Drawings: Focus on individual parts with all dimensions and specifications.

- Assembly Drawings: Show how multiple parts fit together to form a full product.

- CAD Drawings: Digital versions created using computer-aided design software, often used for CNC machining.

- Mechanical Drawings: Broad category covering any drawings related to mechanical systems or components.

Understanding these types of drawings helps you identify exactly what information you need, whether you’re designing a part or preparing for CNC machining.

The Role of Engineering Drawings in CNC Machining

Engineering drawings play a crucial role in CNC machining by ensuring every part is made with precision and accuracy. These technical drawings act as the blueprint CNC machines follow to cut, shape, and assemble components exactly as designed. Without detailed engineering blueprints or CAD drawings, CNC machining would lack the clear instructions needed for consistent quality.

These drawings serve as a bridge between design and manufacturing, translating ideas into practical, usable parts. They provide all the details—dimensions, tolerances, materials—that CNC operators rely on to produce pieces that fit and function perfectly.

In the industry, engineering drawings are essential in fields like automotive, aerospace, medical, and industrial equipment manufacturing. Whether it’s mechanical drawings for engine parts or assembly drawings for machines, accurate CNC machining drawings keep production smooth and precise, the high standards expected in U.S. manufacturing today.

Standards and Best Practices for Engineering Drawings

Common Standards

Engineering drawings follow specific standards to ensure clear communication across design and manufacturing teams. The most widely used standards in the U.S. include ASME Y14.5 for dimensioning and tolerancing and ISO standards that cover everything from symbols to line types. These standards help avoid confusion by setting rules on how details are displayed, measured, and interpreted, which is essential for precision manufacturing and CNC machining.

Best Practices for Creating Drawings

Creating effective engineering drawings means keeping things accurate and easy to understand. Here are some best practices we follow:

- Keep dimensions clear and consistent

- Use layered CAD drawings to separate different parts or views

- Label all features correctly with tolerances and notes

- Include both detail drawings and assembly drawings when needed

- Review and update drawings regularly to reflect design changes

Following these steps reduces errors during CNC machining and speeds up production.

Digitization and Modern Trends

Digital engineering drawings are becoming the norm. CAD drawings allow for faster edits and easier sharing online, improving collaboration between engineers and manufacturers. Digitized engineering drawings also integrate smoothly with CNC machines, reducing manual input and increasing accuracy. Another trend is the use of 3D models alongside 2D drawings to give a clearer view of complex parts.

At HYCNC, we leverage these modern tools to streamline our CNC machining services, offering clients quicker turnaround times and precision results. For more on improving workflows, check out our tips for reverse engineering.

How HYCNC Utilizes Engineering Drawings

At HYCNC, we rely heavily on detailed engineering drawings to ensure every CNC machining project meets exact specifications. Our process starts with a thorough review of your engineering blueprints or CAD drawings. We focus on the key components, including mechanical drawings and assembly drawings, to fully understand your design intent. This step helps us prepare precise CNC machining drawings, so production runs flawlessly.

HYCNC’s Process

- Detailed Analysis: We study your technical drawings carefully to identify all critical details.

- Programming: Next, we convert those details into CNC programs using advanced software.

- Simulation: We run simulations to confirm the precision and accuracy of the machining process.

- Production: Finally, we use those digitized engineering drawings to guide our machines in creating parts exactly as designed.

Benefits for Clients

Using engineering drawings in this way offers several advantages:

- Accuracy: Reduced errors and tighter tolerances.

- Consistency: Repeatable quality across production batches.

- Time Savings: Faster setup times thanks to clear, detailed drawings.

- Cost Efficiency: Less material waste and fewer reworks.

Client Collaboration

We believe the best results come from strong teamwork. HYCNC collaborates closely with clients throughout the project:

- Design Feedback: We provide insights and suggestions based on our machining experience.

- Revisions: Quick updates to drawings or programs if needed.

- Transparent Communication: Keeping you informed every step of the way.

If you’re interested in reverse engineering or need help optimizing your technical drawings, check out our tips for reverse engineering for more insights and practical advice.

At HYCNC, our use of engineering drawings ensures your ideas turn into precision parts that perform as intended.

Challenges and Solutions in Engineering Drawings

Common Challenges

When working with engineering drawings, several issues can come up:

- Misinterpretation: Even small mistakes in reading technical drawings or CAD drawings can lead to costly errors in CNC machining.

- Outdated or unclear drawings: Using old or poorly detailed engineering blueprints can cause delays and inaccuracies.

- Lack of standardization: Inconsistent use of engineering drawing standards makes it hard to ensure precision manufacturing.

- Communication gaps: Poor collaboration between designers, engineers, and machinists often leads to confusion.

- Digitization issues: Losing details or introducing errors during the transition from paper to digitized engineering drawings.

Solutions

Here’s how we tackle these challenges to keep things on track:

- Clear and detailed drawings: We make sure every CAD drawing and mechanical drawing includes all necessary details, minimizing guesswork.

- Adhering to standards: Using common engineering drawing standards helps everyone speak the same language, improving accuracy.

- Regular updates and reviews: Keeping drawings current and reviewing them thoroughly prevents outdated info from creeping in.

- Strong communication: We foster ongoing collaboration between our team and clients to address questions before they become problems.

- Leveraging technology: Using advanced software for digitized drawings ensures precision, easy updates, and seamless integration with CNC machining processes.

By focusing on these solutions, we reduce errors and speed up production while delivering quality CNC service to our clients.

How to Get Started with Engineering Drawings for CNC Machining

For Beginners

Starting with engineering drawings for CNC machining can seem tricky, but it doesn’t have to be complicated. Here’s a simple approach:

- Learn the basics: Understand key terms like technical drawings, detail drawings, and CAD drawings.

- Use software tools: Start with beginner-friendly CAD programs (like Fusion 360 or SolidWorks) that help create clear mechanical drawings.

- Focus on precision: Make sure your drawings include exact measurements and tolerances—these details matter a lot in CNC machining.

- Study examples: Look at engineering blueprints and CNC machining drawings to get a feel for the layout and standards.

- Ask for feedback: If you’re working with a CNC service, share your draft drawings early so they can provide pointers or improvements.

For Businesses

If you run a business and want to integrate engineering drawings into your CNC machining process, here’s how to start effectively:

- Invest in standards: Adopt common engineering drawing standards to maintain consistency across your projects.

- Train your team: Make sure your designers and engineers know how to create accurate assembly drawings and detail drawings suitable for CNC machining.

- Use digitized engineering drawings: Move towards CAD-based, digitized workflows for faster edits and better collaboration.

- Collaborate closely with CNC providers: Share your drawings early and ask for feedback to avoid costly mistakes.

- Utilize professional support: Services like HYCNC can help interpret and refine your drawings to match manufacturing needs, ensuring precision manufacturing and timely delivery.

Getting started right with your engineering drawings sets the foundation for smooth CNC machining and helps avoid common headaches down the line.