Definition of CNC Machining

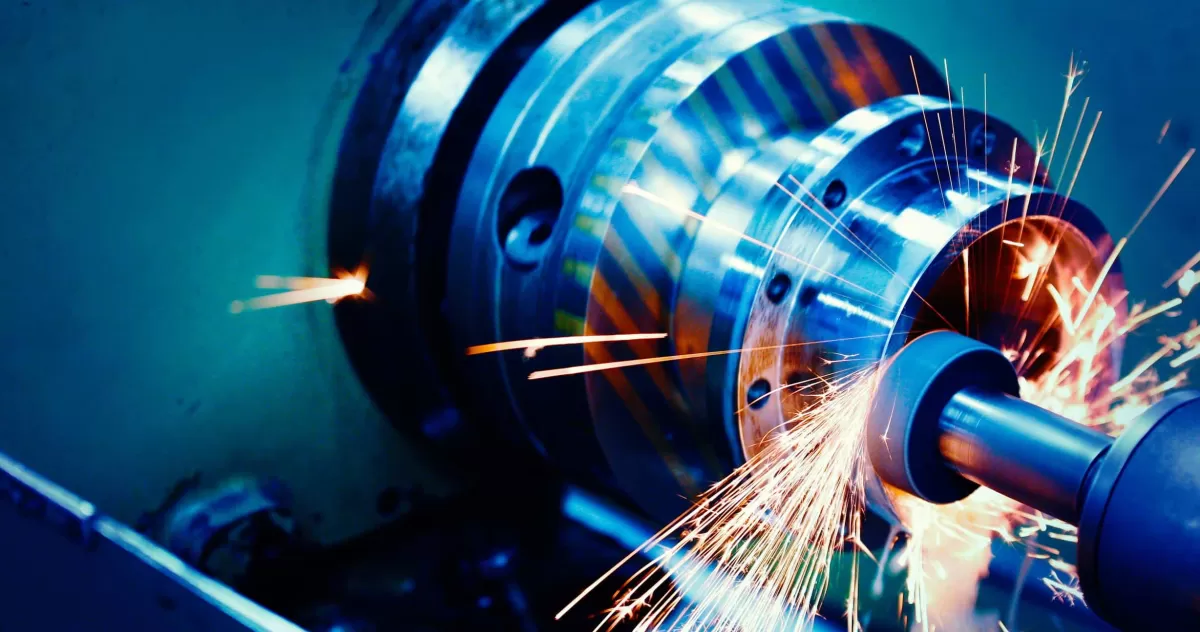

CNC machining stands for Computer Numerical Control machining. It is a manufacturing process where pre-programmed computer software guides the movement of tools and machines to shape raw materials into precise parts. Unlike traditional manual machining, CNC uses automated commands from software to control cutting tools, making the process highly accurate and consistent.

At its core, CNC machining is a type of subtractive manufacturing. This means it starts with a solid block of material, such as metal, plastic, or wood, and removes material layer by layer until the desired shape is achieved. This contrasts with traditional machining where operators manually control tools, often leading to more variability and slower production.

With CNC machining, the use of computer control allows for complex shapes, tight tolerances, and repeatable results. It’s essential in modern manufacturing for producing parts that require high precision and quality.

How CNC Machining Works

CNC machining starts with designing the part using CAD (Computer-Aided Design) software. This step lets us create a detailed 3D model of the product you want. Once the design is ready, we move to the programming phase, where CAM (Computer-Aided Manufacturing) software turns the CAD file into G-code—a set of instructions the CNC machine understands.

Next comes machine setup. We load the material, attach the right tools, and input the G-code. From there, the CNC machine takes over, automatically cutting, drilling, or shaping the material with high precision. Automation in CNC machining means less manual intervention and consistent accuracy on every piece.

At HYCNC, we use advanced CNC machines equipped with the latest automation technology to ensure top-notch precision and efficiency. This combination of software and high-tech hardware lets us offer reliable, fast, and exact custom machining services tailored to your needs.

Types of CNC Machines

CNC machining covers a range of machine types, each designed for specific tasks and materials. Here’s a quick look at the main types:

CNC Mills

These machines cut and shape materials by moving a rotating tool across the workpiece. They’re great for making parts with complex shapes, holes, and slots. You’ll find CNC mills commonly used in aerospace and automotive parts production.

CNC Lathes

Lathes spin the material while cutting tools shape it, perfect for round or cylindrical parts like shafts and bushings. They handle tasks like turning, threading, and drilling with high precision.

CNC Routers

Similar to mills but typically used on softer materials such as wood, plastic, and composites. CNC routers are popular for signage, cabinetry, and mold making.

CNC Plasma Cutters

These use a focused plasma jet to cut through conductive metals like steel and aluminum. They’re best for fast, rough cuts, often used in construction and metal fabrication.

CNC Laser Cutters

Laser cutters use a high-powered beam to cut or engrave materials with extreme precision. They work well on thin metals, plastics, and even wood, ideal for electronics housing and custom decorative parts.

CNC EDM (Electrical Discharge Machining)

EDM removes material with electrical sparks, perfect for hard metals or complex shapes that are tough to machine conventionally. You’ll see CNC EDM used for molds, dies, and intricate medical components.

Each type offers unique advantages depending on the job, material, and final product requirements. At HYCNC, we provide access to all these CNC machine types to meet a wide range of manufacturing needs across industries.

Applications of CNC Machining

CNC machining plays a big role across many industries here in the U.S. It’s essential in aerospace for making aircraft parts that demand high precision and durability. In the automotive world, CNC helps produce everything from engine components to custom body parts. The medical field relies on CNC machining for surgical tools, implants, and devices where accuracy is critical. Electronics manufacturers use CNC for intricate components like circuit boards and housings.

Some common products made with CNC machining include turbine blades, car transmission gears, orthopedic implants, and precision electronic enclosures. These items need consistent quality and tight tolerances, which CNC machining delivers.

At HYCNC, we understand the unique needs of each of these industries. Our advanced CNC equipment and expert team help businesses across aerospace, automotive, medical, and electronics sectors get exactly what they need—from prototype runs to full-scale production. We focus on delivering precision, repeatability, and quick turnaround to keep your projects moving smoothly.

Benefits of CNC Machining

CNC machining offers several key benefits that make it a top choice for precision manufacturing in the U.S. market.

-

Precision and Accuracy: CNC machines follow exact digital instructions, delivering tight tolerances every time. This means parts come out consistently accurate, which is crucial for aerospace, medical, and automotive components.

-

Efficiency and Repeatability: Once programmed, CNC machines can produce the same part repeatedly without lost time or mistakes. This reduces waste and speeds up production runs, keeping costs down.

-

Versatility with Materials: CNC machining works with a broad range of materials—from metals like aluminum and steel to plastics and composites. This flexibility allows for custom machining services tailored to specific project needs.

-

Cost-Effectiveness: By minimizing human error and speeding up production, CNC machining lowers overall manufacturing costs. Plus, fast setup times mean quicker delivery for your orders.

At HYCNC, we prioritize these benefits through our advanced equipment and skilled team. Our commitment ensures you get high-quality parts with precision, efficiency, and reliability every time. To learn more about our capabilities, check out our CNC machining services.

CNC Machining vs Other Manufacturing Methods

When it comes to manufacturing, CNC machining stands out by using a subtractive process, where material is removed to create parts. This contrasts with additive manufacturing, like 3D printing, which builds parts layer by layer, and formative manufacturing, where material is shaped through molding or forging.

When to choose CNC machining:

- Need high precision and tight tolerances

- Working with metals or hard materials

- Producing durable, functional parts

- Requiring repeatability for large batches

- Designing complex shapes that need smooth finishes

Additive manufacturing is great for rapid prototyping or complex geometries with lower strength. Formative methods are often faster and cheaper for simple, high-volume parts but are less flexible for custom or small-batch runs.

At HYCNC, we understand these differences deeply. We help you pick the right method based on your project’s needs, whether that’s CNC machining for precision parts or combining processes for the best results. Our expertise ensures you get the quality and efficiency your business demands without overspending or delays.

Choosing a CNC Machining Service Provider

Picking the right CNC machining service provider is crucial for getting quality results on time and on budget. Here’s what you should look for:

- Experience: Look for a provider with a solid track record in CNC machining. Years of experience mean they know how to handle different materials and complex projects.

- Equipment: Advanced, well-maintained CNC machines matter. More versatile and up-to-date equipment means smoother production and better precision.

- Certifications: Industry certifications show the provider meets important quality and safety standards. This ensures your parts will be reliable.

- Material Versatility: Your partner should work with a wide range of materials—metals, plastics, composites—so they can meet whatever your project demands.

- Quality Control: Consistent quality checks and testing guarantee your parts meet specs every time.

- Rapid Prototyping: Fast turnaround on prototypes helps speed up development and get your product to market quicker.

At HYCNC, we tick all these boxes. We combine extensive experience with top-tier equipment and strict quality controls. Our team handles everything from rapid prototyping to full production runs, making us a trusted choice for businesses across the U.S. Looking for reliable custom machining services? HYCNC is ready to deliver precision, efficiency, and consistency you can count on.

Future Trends in CNC Machining

CNC machining is evolving fast with advances in automation and artificial intelligence. These technologies help machines run smarter, faster, and with less human intervention. This means better precision and shorter turnaround times, which is a big win for custom machining services.

There’s also a clear shift toward high-mix, low-volume production. Instead of making huge batches of the same part, manufacturers need flexibility to produce smaller runs of varied parts quickly. CNC machining fits this demand perfectly since it’s easy to switch designs and materials without retooling.

Sustainability is another growing focus. Efficient CNC processes reduce waste and energy use, which minimizes environmental impact. At HYCNC, we prioritize green manufacturing by using energy-efficient machinery and recycling materials wherever possible.

We stay ahead by adopting these trends early—leveraging AI-driven controls, flexible setups for diverse production runs, and eco-friendly practices. This ensures we continue delivering top-quality CNC machining services that meet the evolving needs of U.S. industries.