What Are Locating Features in Weldments

Locating features are specially designed elements like tabs, slots, dowel pins, and rectangular cutouts integrated into weldments to ensure precise alignment during assembly. These features act as built-in guides, helping parts fit together accurately without the need for complex fixturing or manual adjustments.

For example, in an adapter mount weldment, rectangular tabs might slot perfectly into matching cutouts on the base plate, ensuring each component sits exactly where it should. This built-in alignment reduces setup time and minimizes the risk of errors during welding.

At HYCNC, we customize locating features to fit your specific projects, enhancing both precision and efficiency. Our CNC services allow us to create highly accurate tabs, slots, and pins tailored to your weldment design, helping you save time and streamline fabrication from the ground up.

Why Locating Features Save Time in Weldment Fabrication

Locating features like tabs, slots, and dowel pins help cut down setup time by reducing the need for complicated jigs or fixtures. Instead of spending hours positioning parts, these features guide pieces into the right spot quickly and consistently.

They also boost repeatability, meaning each weldment lines up the same every time. This lowers the chance of errors and costly rework, which can slow down production significantly.

Assembly moves faster too because parts fit together perfectly without extra adjustments. That smooth fit speeds up the whole process from start to finish.

For example, one HYCNC client used custom locating features on their adapter mount weldments and saved about 30% on assembly time. This shows how smart design paired with precise CNC machining can make a real difference in fabrication efficiency.

Designing Effective Locating Features in CAD Software

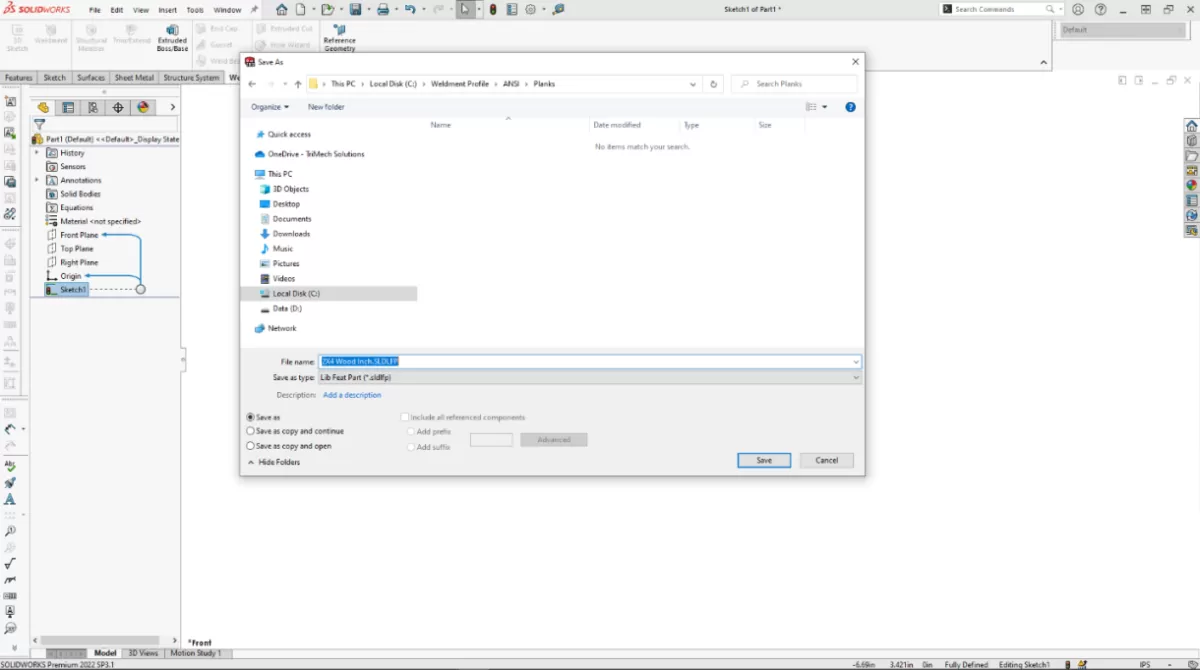

Using CAD software like SOLIDWORKS Weldments makes designing locating features straightforward and efficient. These tools help you create precise tabs, slots, dowel pin holes, and custom profiles that ensure your weldments fit together perfectly.

Here’s a simple way to design locating features in CAD:

- Start with sketches: Draw basic shapes for tabs or slots on the weldment parts.

- Add locating features: Use SOLIDWORKS’ Locate Profile tool to position tabs and slots where they best align components.

- Customize profiles: Modify the shape and size to fit your specific needs, improving fit and reducing assembly errors.

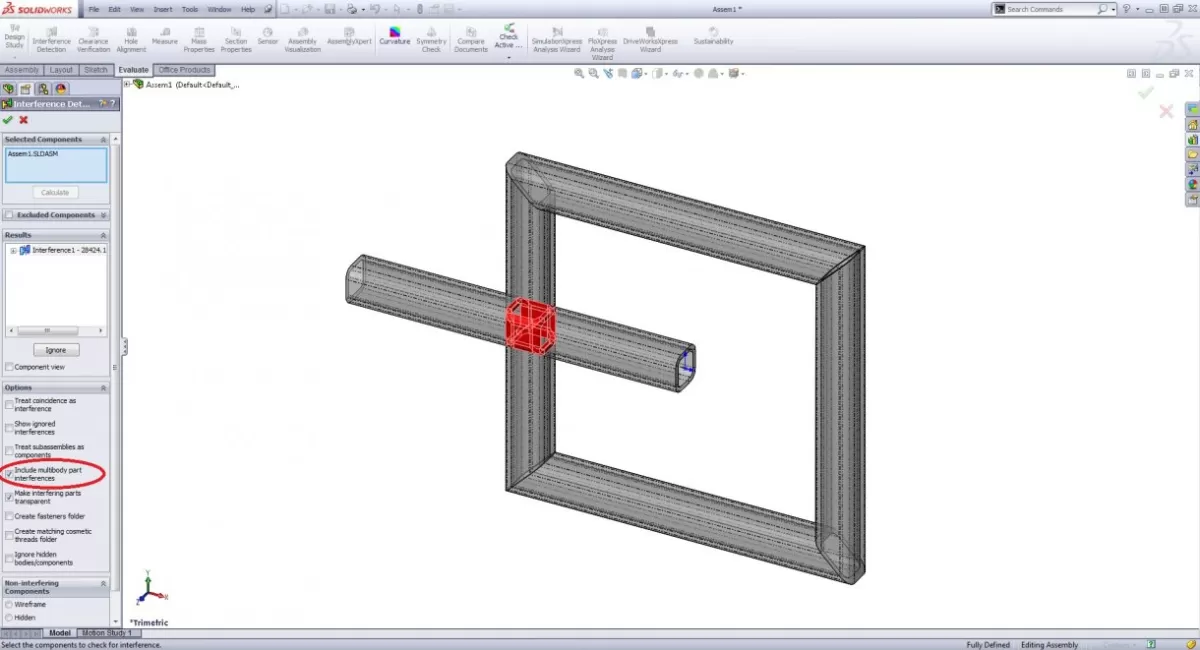

- Check fit and clearance: Use CAD’s built-in tools to simulate assembly and confirm everything lines up.

At HYCNC, we support you through this design process. Our team can help optimize your CAD models for CNC machining, ensuring your locating features are both accurate and easy to manufacture. This reduces costly mistakes and speeds up your entire fabrication workflow.

Practical Examples of Locating Features in Weldment Projects

When working on weldment projects, using the right locating features can make all the difference. Here are some practical examples that show how these features speed up fabrication and improve accuracy.

-

Rectangular Tabs and Slots

These are common in plate-based weldments. Tabs fit precisely into matching slots to keep parts aligned during welding. This simple design cuts down on setup time and reduces the need for extra fixtures.

-

Dowel Pins for Structural Alignment

For complex weldments with multiple structural members, dowel pins ensure everything lines up perfectly. They act as precise guides, so you don’t have to spend hours checking measurements or adjusting parts.

-

Custom Profiles Designed with HYCNC Expertise

Sometimes standard tabs and pins don’t cut it. That’s HYCNC’s custom CNC profiles come in. We can unique locating features tailored exactly to your design, making assembly faster and more reliable.

-

Visual Aids for Feature Fitment

To help you see how these features work together, we provide detailed visual aids with every project. These diagrams and 3D models show the fit and alignment clearly, helping prevent mistakes before cutting begins.

-

Precision CNC Cutting from HYCNC

All locating features benefit from HYCNC’s precision CNC cutting. Our laser cutting and milling machines deliver tight tolerances and smooth edges, so your weldment pieces fit together perfectly every time, saving you time and headaches on the shop floor.

Using these proven locating features in your weldment designs will streamline assembly and improve overall quality — exactly what we deliver here at HYCNC.

Best Practices for Implementing Locating Features

Keeping locating features simple is key to cutting down machining time and saving costs. Avoid making designs too complex—simple tabs, slots, or pins do the job without adding extra machine hours.

Make sure your locating features work well with both CNC machining and welding. Features should fit the capabilities of the machines and not interfere with weld access or strength.

Using symmetry and mirroring in your designs helps speed up fabrication. When parts are balanced and repeatable, setup and machining go smoother, reducing errors and lead times.

Always work closely with the HYCNC team during the design phase. Our experts can review your locating features for manufacturability, suggest improvements, and help validate your design before production. This collaboration ensures your weldment assembly is efficient, precise, and cost-effective.

How HYCNC Enhances Weldment Efficiency with CNC Services

At HYCNC, we bring top-notch CNC capabilities to your weldment projects, including laser cutting, milling, and welding support. This combo lets us create precise locating features like tabs, slots, and dowel pin holes that fit perfectly every time. By integrating these features directly into your custom weldments, we help reduce assembly time and the need for complicated fixtures.

Partnering with HYCNC means faster turnaround, less waste, and cost savings through our precise machining and experienced welding support. We work closely with you to optimize designs for CNC efficiency, ensuring your parts align perfectly and weldments come together smoothly.

Ready to save time and cut costs on your next weldment project? Contact HYCNC today for a free consultation and see how our CNC services can boost your fabrication process.

Common Mistakes to Avoid When Using Locating Features

When adding locating features to your weldments, it’s easy to slip up. Here are some common mistakes to watch out for:

-

Overcomplicating designs: Trying to add too many tabs, slots, or pins can slow down CNC machining, increasing costs and lead times. Keep locating features simple and effective.

-

Ignoring tolerances: Even small gaps or misalignments can cause big issues during assembly. Make sure to set realistic tolerances that allow parts to fit perfectly without extra adjustments.

-

Skipping updated documentation: Always keep your cut lists, bill of materials (BOMs), and CAD files current. Outdated documentation leads to errors on the shop floor and wasted time.

At HYCNC, our quality control process catches these problems before cutting starts. We ensure your locating features are accurate and ready for flawless weldment assembly. This reduces rework and keeps your projects on schedule.

Measuring the Impact Time and Cost Savings

When you use locating features in weldments, the time savings quickly add up. By cutting down on complex fixturing, setup times drop dramatically—clients working with HYCNC have reported up to a 30% faster assembly process. This speed boost means projects finish sooner and flow smoother.

On the cost side, less rework happens because parts align perfectly the first time. Using fewer tools and simpler fixtures also lowers overhead. Higher productivity comes from fewer mistakes and quicker turnaround. These savings combine to make a noticeable difference in your shop’s bottom line.

HYCNC’s case show real results: customers benefit from precision CNC cutting and expert support, leading to consistent time and cost reductions. Whether you’re producing custom weldments or standard runs, investing in good locating features with HYCNC’s help pays off with measurable improvements in efficiency.