Key Factors Influencing CNC Machined Parts Delivery Time

When you’re waiting on CNC machined parts, a common question is: how long will it take? The delivery time depends on several important factors that impact the entire production process. Here’s what usually affects CNC machining lead times:

Part Complexity

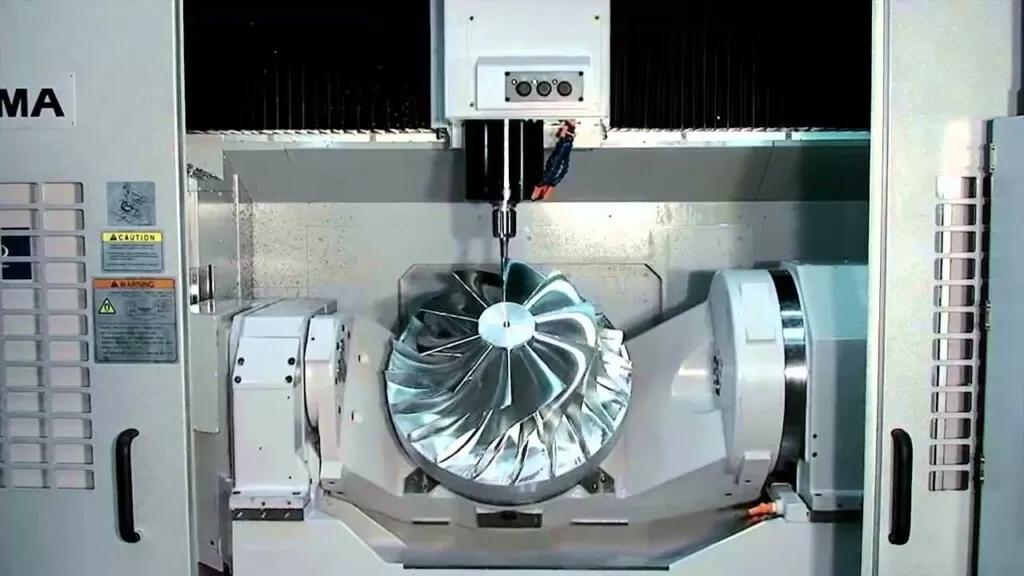

More complex parts with intricate details or multiple features take longer to program and machine. For example, parts needing 5-axis CNC machining or complicated shapes often require more setup and machining time.

Material Selection

Different materials machine at different speeds. Softer metals like aluminum can be cut faster than harder materials like stainless steel or titanium. Rare or custom materials may also add sourcing delays.

Order Volume

The number of parts you need plays a big role. Prototyping or small batches usually have quicker turnaround times. Large production runs take longer overall but sometimes benefit from optimized CNC production timelines.

Tolerance and Precision Requirements

Tighter tolerances or higher precision increase the machining complexity. Achieving exact measurements requires slower machining feed rates and extra inspection steps, which extend delivery times.

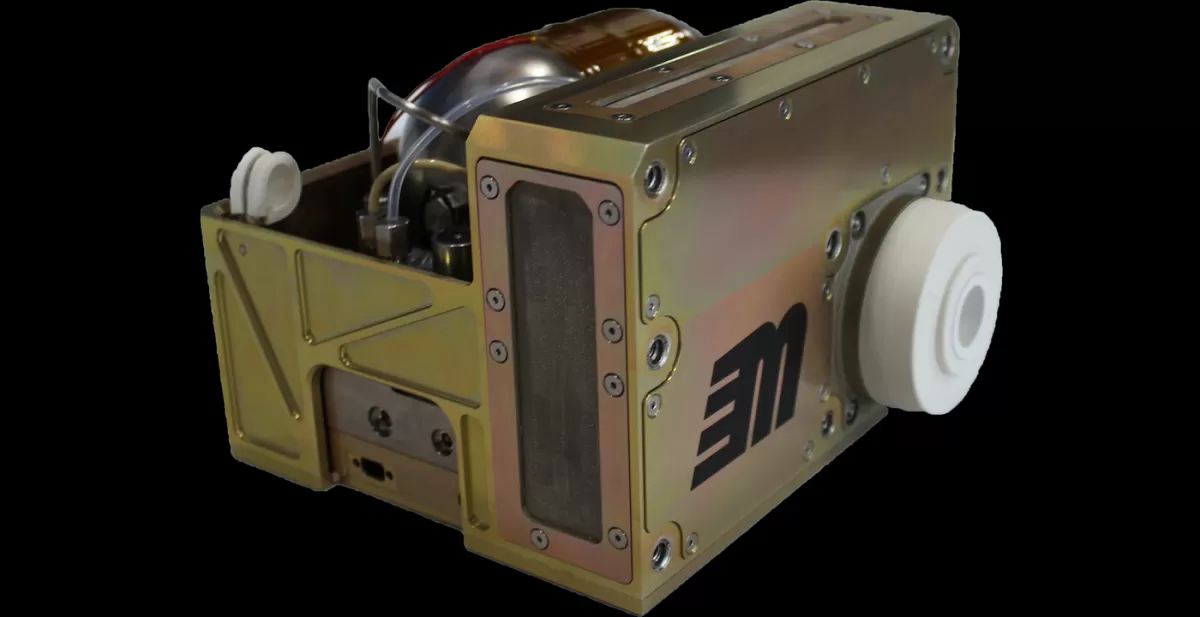

Specialized Tools and Processes

If your part needs custom tooling, inserts, or special machining processes like surface finishes or thread milling, expect additional setup and machining time.

Post-Processing Requirements

Parts needing secondary processes such as deburring, heat treatment, anodizing, or painting add to the total lead time. These finishing steps are essential for many precision parts but can slow down delivery.

Understanding these factors helps set clear expectations for CNC machined parts delivery. Knowing what influences lead times also empowers you to plan better and communicate effectively with your CNC machining service provider.

Typical Delivery Timelines for CNC Machined Parts

Delivery times for CNC machined parts vary depending on the type of order. Here’s a quick look at typical timelines:

Prototyping

CNC prototype turnaround is usually the fastest since these are one-off or low-quantity jobs. Expect delivery within 3 to 7 business days. Quick prototypes help you test designs and make adjustments before moving to full production.

Small to Medium Production Runs

For small to medium production runs, the CNC production timelines often range from 1 to 3 weeks. This depends on order volume, complexity, and material availability. These runs are great for limited batches or pilot projects.

Large Production Runs

Large production runs take longer, generally 3 to 6 weeks or more. This timeline factors in machine setup, bulk material sourcing, and quality control checks. While the lead time is longer, prices usually get better with volume.

Knowing these typical delivery schedules helps you plan better and meet your project deadlines without last-minute surprises.

How to Optimize CNC Machining Delivery Times

speeding up CNC machined parts delivery starts with a few smart moves on your end. Here’s what works best:

Simplify Designs

Keep your parts as simple as possible. Complex shapes or tight tolerances slow down CNC machining lead times. Straightforward designs mean quicker setups and faster production.

Choose Readily Available Materials

Opt for materials that your CNC machining service provider stocks or has easy access to. Exotic or rare metals add delays waiting for supplies.

Provide Clear Specifications

Make sure your drawings and instructions are complete and easy to understand. Missing details or unclear specs cause back-and-forth that slows down your CNC prototype turnaround and final CNC production timelines.

Partner with an Efficient CNC Service Provider

Work with a provider that’s known for fast, reliable delivery and uses advanced tech. An experienced team with streamlined processes reduces hold-ups.

Consider Expedited Services

If time is tight, ask about rush options. Many CNC machining service providers offer expedited services for an extra fee to speed up your order without sacrificing quality.

By focusing on these areas, you can cut down CNC machined parts delivery time and keep your projects moving smoothly.

Why Choose HYCNC for Timely CNC Machined Parts Delivery

When it comes to delivering CNC machined parts on time, HYCNC stands out because we combine advanced technology with efficient processes designed to meet tight deadlines. Here’s why partnering with us makes a difference:

Advanced Technology

We use the latest CNC machines, including 5-axis CNC machining, to speed up production without sacrificing precision. This lets us handle complex parts faster and more accurately, reducing lead times significantly.

Streamlined Processes

At HYCNC, every step—from quoting to shipping—is optimized to move smoothly and quickly. Our experienced team ensures minimal downtime, efficient tool changes, and quick setups to keep your parts moving through production.

Transparent Communication

We keep you in the loop from day one. You’ll get clear updates on your CNC machined parts delivery status, so you can plan your next steps confidently. No surprises, just straight answers.

Proven Reliability

Thousands of customers trust us for on-time delivery and high-quality parts. Our track record speaks for itself—consistent, dependable CNC machining lead times help you avoid costly project delays.

Global Reach

Serving businesses across the United States and beyond, HYCNC delivers your custom CNC parts production wherever you need them. Our logistics network ensures fast and safe delivery, so your parts arrive when promised.

Choosing HYCNC means choosing a CNC machining service provider committed to precision parts delivery time that meets your schedule, every time. For more tips on optimizing your parts design for speed, check out our design tips for CNC milled low volume parts.

Frequently Asked Questions

How long does it take to deliver CNC machined parts?

Delivery time depends on part complexity, material, order size, and precision. Typically, prototypes take a few days to a week, small to medium runs a couple of weeks, and large production runs may take several weeks.

What are the main factors affecting CNC machining lead times?

Key factors include part design complexity, material selection, volume of parts, tolerance requirements, need for specialized tools, and any post-processing like finishing or coating.

Can I speed up CNC prototype turnaround?

Yes. Simplify your design, choose common materials, provide clear specs, and work with a CNC machining service provider that offers expedited services.

How does material choice impact CNC machined parts delivery?

Materials that are readily available or easier to machine usually reduce lead times. Exotic or hard-to-machine materials can extend production timelines.

What is a typical CNC production timeline for custom parts?

Prototyping: 3-7 days

Small to Medium runs: 1-3 weeks

Large runs: 3+ weeks depending on volume and complexity

Why choose a local CNC machining service provider?

Local partners offer faster communication, quicker shipping, and better support. This keeps your project moving smoothly and helps ensure precision parts delivery time meets your needs.

Does the level of precision affect CNC machining speed?

Yes, tighter tolerances and higher precision usually mean slower machining and longer delivery times due to more careful processing and inspection.

Are expedited CNC machining services available?

Many providers, including HYCNC, offer rush options for urgent jobs. Keep in mind this might increase cost but can significantly cut down lead times.