What is CNC Milling

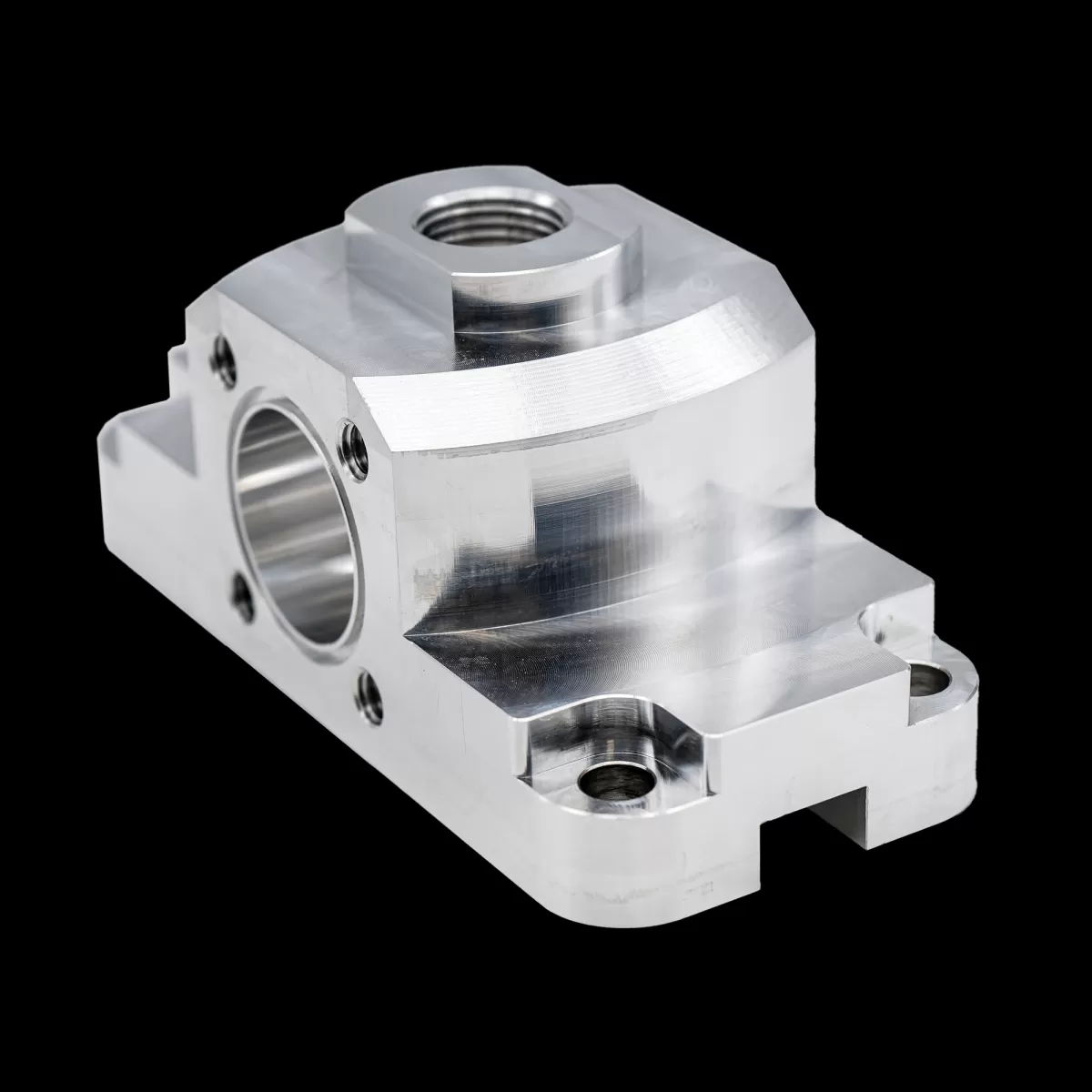

CNC milling is a precise subtractive manufacturing process where a computer-controlled machine removes material from a workpiece to create a desired shape. It uses rotary cutting tools to carve out metal, plastic, or other materials with high accuracy and repeatability.

Key Features

- Computer Numerical Control for automation and accuracy

- Single or multi-axis movement for complex shapes

- Versatile tooling options for different materials and cuts

- Excellent precision and surface finish

- Suitable for both prototypes and production runs

Applications

CNC milling is widely used in industries such as aerospace, automotive, electronics, and medical devices. It is perfect for creating parts like gears, brackets, molds, and components with intricate details.

HYCNC Expertise

At HYCNC, we specialize in advanced CNC milling services tailored to your project needs. Our skilled team uses state-of-the-art equipment to deliver high-quality parts on time. Whether you need precision prototypes or small-to-medium production runs, we bring extensive experience and solutions that match your goals.

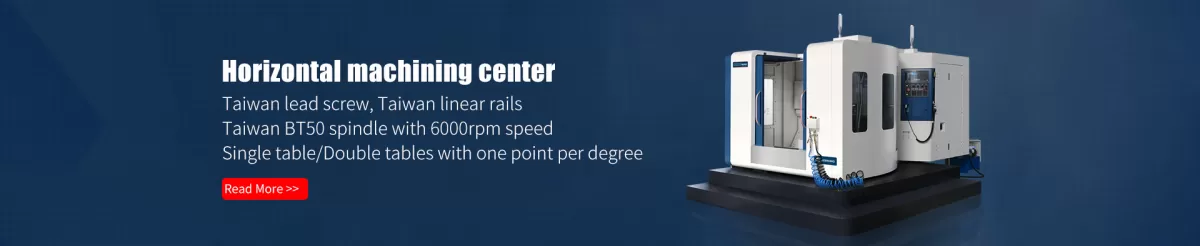

What is a CNC Milling Center

Definition

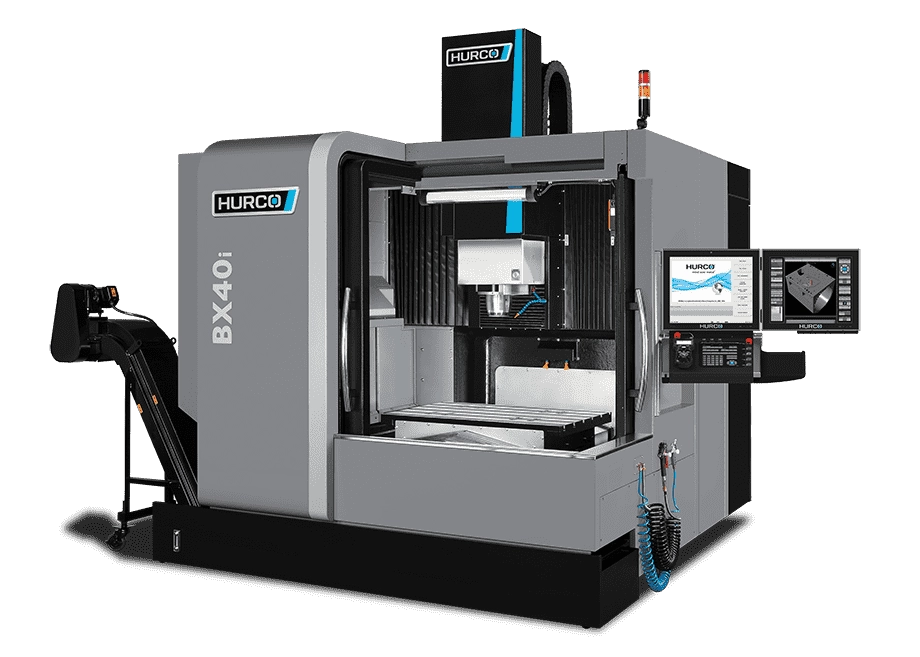

A CNC Milling Center is an advanced type of CNC machining equipment designed for high-precision and efficient milling operations. Unlike standard CNC milling machines, a milling center integrates multiple functions like automatic tool changing and multi-axis movement, allowing complex parts to be produced in one setup.

Key Features

- Automatic Tool Changer (ATC): Enables quick switching between tools without stopping the machine.

- Multi-Axis Machining: Usually 3, 4, or 5-axis capabilities for more complex cuts.

- High Precision and Repeatability: Designed for tight tolerances in production runs.

- Enhanced Automation: Reduces operator involvement and increases throughput.

- Integrated Control Systems: User-friendly CNC controls allow for complex programming and remote monitoring.

Applications

CNC milling centers are widely used in industries requiring precision and complexity, such as aerospace, automotive, medical device manufacturing, and mold making. They excel at producing parts with intricate geometries and tight tolerances, ideal for both prototype and full production runs.

HYCNC’s Capabilities

At HYCNC, we leverage modern CNC milling centers to deliver fast, precise, and cost-effective machining solutions. Our equipment supports multi-axis milling, automatic tool changes, and complex programming, ensuring we meet a variety of client needs from prototyping to large-scale manufacturing. Whether your project demands intricate detail or high-volume efficiency, we have the right milling center technologies to get the job done.

For more details on optimizing part design for CNC milling, check our guide on CNC milling part design.

Key Similarities Between CNC Milling and CNC Milling Centers

When comparing CNC milling vs CNC milling centers, it’s clear they share several important qualities that make both reliable for precision machining.

Subtractive Manufacturing

Both CNC milling machines and CNC milling centers follow the subtractive manufacturing process. That means they start with a solid block of material and carefully remove parts of it to create the final shape. This makes them perfect for cutting complex parts from metal, plastic, or other materials.

Computer-Controlled Precision

At their core, both use computer numerical control (CNC) to guide the cutting tools with high accuracy. This ensures consistent results, tight tolerances, and repeatable quality, whether manufacturing a single prototype or a full production run.

Material Versatility

CNC milling and CNC milling centers handle a wide range of materials. From aluminum and steel to plastics and composites, they can work with many types to suit different industry needs.

Common Applications

You’ll find both technologies in similar applications: automotive parts, aerospace components, medical devices, and custom machinery parts. Both are crucial for industries that require intricate shapes and precise dimensions.

HYCNC’s Unified Approach

At HYCNC, we use both CNC milling machines and advanced CNC milling centers to offer flexible machining solutions. This unified approach lets us optimize efficiency and quality for your specific project, whether you need simple or complex parts. Our expertise ensures you get the best fit between technology and your product goals.

Key Differences Between CNC Milling and CNC Milling Centers

When deciding between CNC milling and a CNC milling center, there are some important differences to keep in mind:

Automation Level

- CNC Milling typically involves manual tool changes and setups, requiring more hands-on operator control.

- CNC Milling Centers come equipped with Automatic Tool Changers (ATCs), allowing them to switch tools on the fly without stopping. This boosts automation and reduces downtime.

Complexity and Efficiency

- CNC Milling is great for simpler parts or lower volume runs and offers flexibility with straightforward operations.

- CNC Milling Centers handle complex, multi-axis machining more efficiently, making them ideal for intricate parts and high production volumes.

Cost and Investment

- CNC Milling machines generally require a lower upfront investment, making them suitable for smaller shops or projects with limited budgets.

- CNC Milling Centers are a bigger investment due to their advanced features, but they pay off with improved speed and precision over time.

Operator Involvement

- With CNC Milling, the operator is more actively involved—setting up tools, monitoring processes, and making adjustments.

- In contrast, CNC Milling Centers minimize operator input during runs thanks to automation, freeing up staff for other tasks.

Comparison Table

| Feature | CNC Milling | CNC Milling Center |

|---|---|---|

| Automation Level | Low (manual tool changes) | High (Automatic Tool Changer) |

| Complexity Handling | Basic to moderate | Advanced multi-axis machining |

| Efficiency | Moderate | High |

| Initial Cost | Lower | Higher |

| Operator Involvement | High | Low |

| Best Suited For | Small to medium runs | High volume, complex parts |

Understanding these differences helps you choose the right solution for your manufacturing needs. At HYCNC, we can help you evaluate which option fits your project goals and budget.

Choosing Between CNC Milling and CNC Milling Centers

When deciding between CNC milling and CNC milling centers, start by looking closely at your project requirements. If your job involves simple shapes or smaller batch runs, a basic CNC milling machine might be enough. For more complex parts or higher production volumes, a CNC milling center with features like automatic tool changers and multi-axis capabilities can save time and improve consistency.

Budget also plays a big role. CNC milling machines typically cost less to set up and maintain, making them ideal for smaller businesses or projects with tight budgets. CNC milling centers require a bigger upfront investment but offer higher efficiency and automation, which can lower costs over long runs.

Think about your industry’s needs. Aerospace or automotive parts often demand the precision and advanced functions that CNC milling centers provide. Meanwhile, industries like prototyping, custom fabrication, or smaller manufacturers may find traditional CNC milling perfectly suitable.

At HYCNC, we help you make the right choice by assessing your specific needs, budget, and goals. Our expertise covers both CNC milling and milling centers, so we recommend the best fit to ensure you get quality results without overspending.

Benefits of Partnering with HYCNC

When you choose HYCNC for your CNC milling or CNC milling center needs, you get more than just a service provider—you gain a trusted partner.

Expertise in Both Technologies

We know CNC milling and CNC milling centers inside and out. This means no matter your project, we can recommend the best approach for precision and efficiency, saving you time and money.

Custom Solutions

Every project is unique. We offer tailored CNC machining solutions to fit your specific requirements, whether it’s for small batch runs or complex parts. Our flexibility helps you stay competitive in your industry.

Quality Assurance

At HYCNC, quality is non-negotiable. We use state-of-the-art equipment and strict quality checks to ensure your parts meet exact standards. You can count on consistent, reliable results every time.

Call to Action

Ready to improve your manufacturing process with expert CNC milling services? Contact HYCNC today to discuss how we can support your project and deliver top-quality results that meet your needs.

FAQs

Materials Compatibility

At HYCNC, we work with a broad range of materials, from aluminum and steel to plastics and composites. Whether you need CNC milling or CNC milling center services, we ensure your chosen material is machined precisely and efficiently to meet your project needs.

Precision Assurance

Precision is key in CNC machining. Our advanced CNC milling machines and CNC machining centers deliver consistently high accuracy. We use strict quality controls to guarantee every part matches your specifications, so you get reliable and repeatable results.

Small Batch Handling

Got a small batch or prototype project? HYCNC handles low volume runs with the same care as large production jobs. Our flexible CNC milling and CNC milling center services are designed to adapt to your batch size without compromising quality or lead time.

Industries Benefiting

Our CNC milling and CNC machining services support a variety of industries including aerospace, automotive, medical, and electronics. No matter your sector, HYCNC’s expertise helps bring your precision components from concept to completion.

Contacting HYCNC

Ready to discuss your CNC milling or CNC machining center needs? Contact HYCNC today. Our team is here to provide expert advice, custom solutions, and quick quotes to help you make the right choice for your project.