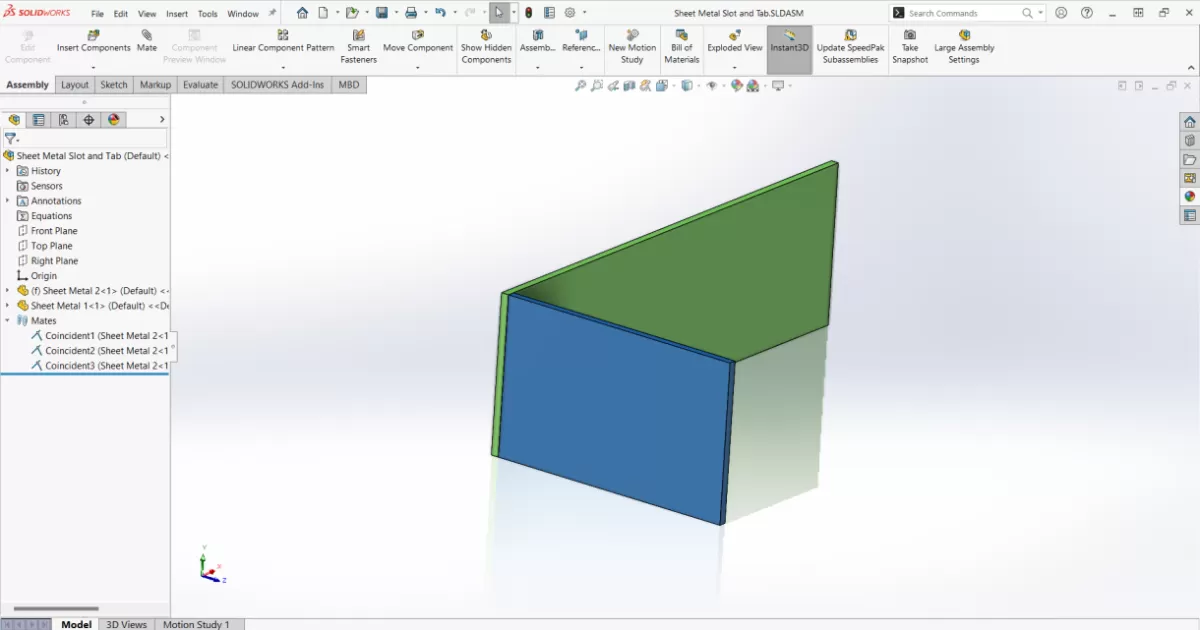

Mastering Tab and Slot Design in SolidWorks for CNC Fabrication

If you’re working with sheet metal or CNC fabrication, mastering tabs and slots in SolidWorks can seriously improve your designs. Tabs and slots are simple features that play a big role in how parts fit together, making assembly easier and more precise. Understanding how to design these features right in SolidWorks not only speeds up your workflow but ensures your parts hold tight during manufacturing.

Why Tabs and Slots Matter in Sheet Metal Design

Tabs and slots are essential for creating interlocking sheet metal components. They act like puzzle pieces, helping parts align perfectly without extra fasteners. This self-fixturing design reduces the chance of misalignment during welding or assembly, which is a common issue in sheet metal fabrication. For CNC machining, tabs and slots simplify setup and improve repeatability, making your production more efficient.

Overview of SolidWorks Tab and Slot Feature

SolidWorks offers a dedicated Tab and Slot feature designed specifically for sheet metal parts. It lets you quickly add tabs or slots by selecting edges or faces, automatically generating clean cutouts or tabs with precise dimensions. This feature supports customization of size, shape, and position, giving you control over fit and tolerance. Combined with other sheet metal tools in SolidWorks, the Tab and Slot feature is a powerful way to optimize your designs for CNC machining and laser cutting.

Getting comfortable with this tool sets you up for faster design cycles and a smoother path from CAD to finished parts, especially when working on complex assemblies. If you want to dive deeper into SolidWorks sheet metal design, check out our detailed guide on designing sheet metal using SolidWorks.

Understanding the Tab and Slot Feature

What Are Tabs and Slots

Tabs and slots are simple yet powerful design elements used in sheet metal and CNC machining to connect parts without extra hardware like screws or welds. Tabs are small protrusions on one part, while slots are matching cutouts on the mating part. When assembled, the tabs fit snugly into the slots, locking the pieces together and ensuring proper alignment.

Key Benefits for CNC Manufacturing

Using tabs and slots in your designs brings several advantages, especially for CNC fabrication:

- Easy Assembly: Parts fit together precisely, reducing the need for clamps or fixtures during assembly.

- Improved Accuracy: Tabs and slots act as guides that keep components aligned and stable.

- Reduced Fasteners: Minimize the use of screws, bolts, or welding, saving time and cost.

- Better Repeatability: Perfect for mass production, ensuring each piece fits the same way.

- Enhanced Structural Strength: Interlocking parts distribute loads more evenly, improving durability.

This feature is especially helpful for CNC machining metal or laser cutting sheet metal parts designed for quick, reliable assembly. For a deeper dive into sheet metal design using SolidWorks, check out our guide on designing sheet metal using SolidWorks.

Step-by-Step Guide to Designing Tabs and Slots in SolidWorks

Setting Up Your SolidWorks Environment

Before you start designing tabs and slots, make sure your SolidWorks setup is ready for sheet metal work and CNC fabrication:

- Enable Sheet Metal Tools: Go to the Add-Ins menu and enable the Sheet Metal feature for easy access.

- Use Proper Units: Work in inches or millimeters depending on your machine specs, but keep it consistent.

- Set Material Thickness: Match your sheet metal thickness to what your CNC will cut — this is crucial for tab fit.

- Open a New Part with Sheet Metal Template: This ensures you have the right default parameters like bend radius and gauge.

Creating Tabs and Slots

SolidWorks has built-in features that simplify tab and slot creation, especially on sheet metal parts:

- Start with a Flat Pattern: Design your main part, then create a flat pattern if you’re using sheet metal.

- Insert Slots: Use the Slot tool to draw your slot geometry. Rectangular or tab-shaped slots work best for interlocking parts.

- Add Tabs: Design tabs as part of the mating edge that will fit into your slots. Make sure to dimension tabs slightly bigger or smaller depending on your fit tolerance.

- Use the Tab and Slot Feature (SolidWorks 2018 and newer): This automates alignment by snapping tabs and slots together. You can find this under the Sheet Metal tab in the Command Manager.

- Adjust Gap Settings: Fine-tune the gap between tabs and slots to allow for material kerf (laser cut width) or CNC tolerance.

Advanced Options for Precision

Going beyond basics can improve fit and function:

- Apply Kerf Compensation: Adjust size to compensate for material removed during laser cutting or CNC milling. This is critical for tight fits.

- Use Configurations: Create different tab and slot sizes within one part file for testing fits or variants.

- Leverage Equations or Design Tables: Automate dimension changes to tabs and slots based on sheet metal thickness or tool diameter.

- Confirm Flat Pattern Accuracy: Always validate your flat pattern matches your tab and slot geometry before exporting for CNC.

Tips for CNC-Friendly Design

Design tabs and slots with CNC machining and laser cutting in mind:

- Keep Slot Length and Width Consistent: Avoid complex shapes that might fail or slow down the CNC process.

- Design Self-Fixturing Connections: Ensure tabs hold parts securely without extra hardware.

- Avoid Sharp Inside Corners: CNC tools can’t make perfect inside corners; add small radii or dog-bone reliefs.

- Limit Number of Tabs and Slots: Too many can weaken your part or make assembly clunky.

- Test Your DXF Export: Use clean, kerf-adjusted 2D sketches when sending files to CNC. For help with DXF exports from SolidWorks, check this guide on Exporting to DXF from SolidWorks.

Following these steps not only streamlines your design process but also ensures your tabs and slots work flawlessly for CNC machining and laser cutting.

Troubleshooting Common Issues Error Handling Managing Multiple Instances in Assemblies

When designing tabs and slots in SolidWorks, running into errors or assembly hiccups is pretty common, especially if you’re working with multiple instances. Here’s how to handle some of the usual problems:

1. Dealing with Error Messages

- Check feature parameters: Make sure your tab and slot dimensions fit within your sheet metal thickness and material limits. Oversized tabs or slots often cause errors.

- Update your SolidWorks version: Some bugs related to the tab and slot feature are fixed in newer releases like SolidWorks 2018 and later. Keeping your software updated helps.

- Look for sketch or feature conflicts: Sometimes tabs or slots overlap or interfere with other features. Use the interference check tool to catch these issues early.

2. Managing Multiple Instances in Assemblies

- Consistent tab and slot placement: When you copy parts or features across assemblies, ensure tabs and slots are positioned precisely to avoid fit issues during CNC machining.

- Use pattern features carefully: SolidWorks assembly techniques like linear or circular patterns should be applied thoughtfully. Misalignment here can cause assembly errors or tabs that don’t lock properly.

- Control configurations: If you’re using multiple configurations in your assembly, verify tab and slot parameters for each to avoid mismatches.

3. General Tips

- Always verify your design with a flat pattern view to spot potential laser cutting or CNC machining problems before sending it out.

- When in doubt, simulate assembly within SolidWorks to ensure all tabs and slots interlock without forcing parts together.

By staying organized and checking these points, you’ll reduce errors and make your CNC machining and assembly process smoother.

Best Practices for Tab and Slot Design

Design for Manufacturability

When designing tabs and slots in SolidWorks, always keep manufacturability in mind. Make sure your tabs fit snugly but aren’t too tight—allow a slight clearance for cutting tolerance. This helps CNC machines handle slight variations without forcing parts together. Also, avoid overly small tabs or slots; these can cause fragile parts or machining issues. Use standard sheet metal thicknesses and consistent slot widths to simplify production and reduce errors.

Enhancing Assembly Efficiency

Tabs and slots are great for self-fixturing parts, speeding up assembly. To get the most out of this:

- Design tabs that guide parts easily into place without forcing.

- Use symmetrical slots when possible to reduce assembly mistakes.

- Consider adding chamfers or tapers to tabs for smoother insertion.

- Keep an eye on orientation so your parts consistently snap or slide together.

This approach saves time on the shop floor and lowers assembly labor costs.

Scaling for Mass Production

For larger production runs, your tab and slot design needs to be repeatable and reliable:

- Standardize your slot dimensions and tab shapes across parts for easy setup.

- Use CAD templates in SolidWorks to quickly generate consistent tab and slot features.

- Plan for CNC tool wear—choose tab sizes that can tolerate minor tool changes without ruining the fit.

- Test prototypes carefully before committing to big batches.

Following these steps keeps your product quality steady and manufacturing costs predictable as you ramp up volume.

For more on solid sheet metal design techniques in SolidWorks, check out designing sheet metal using SolidWorks. It’s a solid resource to combine tab and slot principles with overall sheet metal best practices.

Real-World Applications Industry Examples Success Story with HYCNC

Tabs and slots aren’t just a design detail—they’re game-changers in real-world manufacturing. Industries like automotive, aerospace, and consumer electronics rely heavily on interlocking sheet metal components to speed up assembly and cut costs. Using SolidWorks for tab and slot design means you can create self-fixturing sheet metal parts that fit perfectly every time, reducing the need for extra fasteners or welds.

Take HYCNC, a leading CNC machining service provider in the US, as a great example. They use SolidWorks’ tab and slot features to streamline their customer designs for laser cutting and CNC machining. This approach helps them deliver parts that snap together with minimal cleanup or adjustment, saving hours on assembly lines.

The benefit? Clients get precision CAD design tailored for CNC, which means better quality parts and faster turnaround. This kind of design for manufacturability (DFM) is what helps businesses stay competitive, especially when scaling for mass production. Whether you’re prototyping or working on large orders, mastering tabs and slots in SolidWorks is a solid move to improve your sheet metal project outcomes.