Understanding Material Strength Key Metrics

When selecting materials for CNC machining and industrial use, it’s crucial to understand key strength metrics. These measurements help determine how a material will perform under different conditions.

-

Tensile Strength

This measures how much pulling force a material can withstand before breaking. It’s essential for parts that experience stretching or tension.

-

Compressive Strength

This indicates how much crushing or pushing force a material can handle. It matters for components under heavy loads or pressure.

-

Yield Strength

Yield strength shows the stress level at which a material starts to deform permanently. Knowing this helps avoid parts that bend or warp during use.

-

Impact Strength

This measures a material’s ability to absorb energy and resist sudden shocks without breaking. It’s important in applications where parts may experience sudden hits or drops.

Alongside these strengths, strength-to-weight ratio is key, especially in CNC machining. It balances heavy-duty durability with the need to keep parts lightweight, improving performance and efficiency.

Other important factors include:

- Hardness: The resistance to surface scratching or denting, influencing wear and tool life in machining.

- Machinability: How easily a material can be cut, shaped, or drilled using CNC tools without excessive wear or damage.

Understanding these metrics helps you choose materials that fit your project’s demands, ensure reliability, and optimize manufacturing costs.

The Strongest Materials for CNC Machining and Industrial Use

When it comes to CNC machining and heavy industrial work, using strong materials is a must. Metals like tungsten, titanium alloys, stainless steel, and chromium stand out as some of the toughest options. Tungsten is known for its incredible hardness and heat resistance, making it perfect for parts that face extreme conditions. Titanium alloys offer a great strength-to-weight ratio, which is why they’re widely used in aerospace and medical parts. Stainless steel is a reliable choice thanks to its durability and resistance to corrosion, while chromium adds hardness and wear resistance when alloyed with other metals.

On the non-metal side, materials like graphene and carbon fiber reinforced nylon are changing the game. Graphene is ultra-strong and lightweight, though still emerging in CNC use, while carbon fiber reinforced nylon combines stiffness and impact resistance with reduced weight. These materials are ideal where weight savings matter without sacrificing strength.

In CNC machining, strong materials are essential for producing parts that can handle high stress, wear, and harsh environments. From automotive components to aerospace parts and medical devices, picking the right strong material ensures long-lasting performance and precision.

The Weakest Materials Properties and Limitations

When it comes to weak materials, metals like tin, lead, and gallium often come up. These metals have low tensile and yield strength, meaning they easily deform or break under stress. On the non-metal side, materials like talc and pine wood have low hardness and poor resistance to impact or wear.

These weak materials aren’t a great fit for high stress CNC machining because they can bend, crack, or chip during cutting. Their low strength-to-weight ratio means they can’t handle tough loads without failing. Also, they tend to have poor machinability for precision work, leading to inconsistent finishes and faster tool wear.

In short, tin, lead, gallium, talc, and pine wood are limited by their low durability and weak structural properties. This makes them unsuitable for applications where strong, reliable parts are needed, especially in industrial CNC machining environments where strength and precision matter most.

Comparing Strongest vs Weakest Key Factors for Material Selection

When choosing materials for CNC machining, it’s important to weigh key factors like tensile strength, weight, cost, and machinability. Here’s a simple table to break down how the strongest and weakest materials stack up:

| Material Type | Tensile Strength (MPa) | Weight (g/cm³) | Cost (USD/lb) | Machinability |

|---|---|---|---|---|

| Strongest Metals | 900 – 3000 | 4.5 – 19.3 | High | Moderate to Difficult |

| Strong Nonmetals | 1000 – 5000+ | 1.3 – 2.3 | Moderate | Moderate |

| Weak Metals | 10 – 50 | 7.3 – 11.3 | Low | Easy |

| Weak Nonmetals | 1 – 50 | 0.3 – 1.5 | Low | Easy |

Some key factors to keep in mind:

- Application Environment: Harsh or high-stress environments demand stronger materials to avoid failure.

- Budget: High-strength alloys and advanced composites often come at a premium.

- Machining Needs: Some strong materials may wear down tools faster or require slower cutting speeds.

- Weight Considerations: For aerospace or automotive parts, strength-to-weight ratio is crucial.

- Corrosion Resistance: Stainless steel and titanium shine here, while weak metals like lead corrode easily.

Balancing these factors ensures you pick the right material – not just the strongest or cheapest – but what fits your project needs and machine capabilities best.

Practical Applications in CNC Machining

When it comes to CNC machining, strong materials like titanium alloys, tungsten, and reinforced carbon fiber are game-changers. For example, aerospace parts often use titanium because it combines high strength with low weight, making aircraft components both durable and efficient. Similarly, automotive and medical device manufacturers rely on stainless steel and high-strength alloys for parts that need to withstand heavy use and wear.

Machining weak materials like tin or pine wood, on the other hand, presents challenges. These materials can deform easily or chip during cutting, which affects precision and surface finish. Plus, they may not hold up well under stress, limiting their use in high-performance or structural applications.

At HYCNC, we understand these challenges and offer tailored CNC solutions to meet the demands of strong materials. Our advanced tooling and machining techniques optimize processing for tough metals and composites, ensuring precision and reliability. Whether you’re working with high-strength alloys or delicate composites, HYCNC delivers quality parts designed to perform.

Choosing the Right Material for Your Project

Picking the right material is key to making your CNC project a success. Here’s a simple step-by-step guide to help you choose based on strength, cost, and how you’ll use it:

-

Define Your Needs

What does your project require? High strength, light weight, or corrosion resistance? Knowing this helps narrow down options fast.

-

Consider Strength and Weight

Balancing strength with weight is crucial, especially for parts that need to be durable but not too heavy. Look for materials with a good strength-to-weight ratio, like titanium or carbon fiber.

-

Factor in Cost

Budget matters. Stronger materials like tungsten alloy can get pricey. Sometimes, a durable but more affordable material like stainless steel fits better.

-

Think About Environment

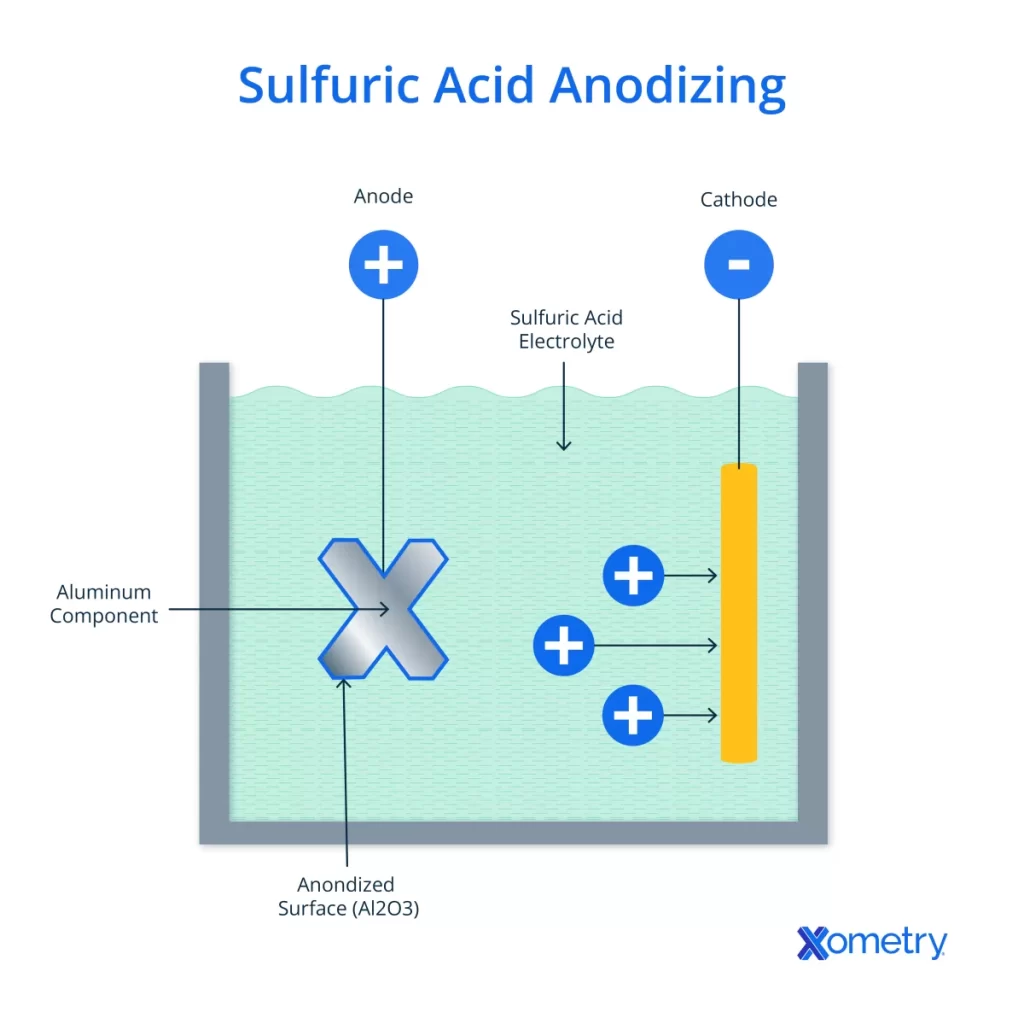

Will your part face moisture, heat, or chemicals? Materials resistant to corrosion, such as anodized aluminum or stainless steel, can save you headaches down the road.

-

Check Machinability

Some materials machine easier, reducing production time and cost. Make sure your choice fits your CNC process capabilities.

-

Consult CNC Experts

Get advice from CNC professionals who understand the nuances of material behavior under machining. They can recommend materials that maximize performance and minimize issues.

-

Balance All Factors

Find the sweet spot between strength, weight, cost, machinability, and corrosion resistance. That blend will deliver the best results for your application.

By following these steps and working with CNC experts, you’ll pick materials that not only meet your project specs but also optimize efficiency and durability on the shop floor.

FAQs on Strongest vs Weakest Materials for CNC Machining

What is the strongest material for CNC machining?

Among metals, titanium alloys, tungsten, and stainless steel rank highly for strength and durability. On the non-metal side, graphene and carbon fiber reinforced nylon are standout strong materials. These materials offer excellent tensile strength, hardness, and resistance to wear, making them ideal for demanding CNC projects.

Can weak materials be used in manufacturing?

Yes, weak materials like tin, lead, or pine wood have specific uses where high strength is not critical. They are easy to machine and cost-effective but unsuitable for high-stress or load-bearing parts. Using weak materials in such applications can lead to failure or excessive wear.

How do you ensure precision machining with strong materials?

Machining high-strength materials requires the right tools and techniques:

- Use cutting tools designed for hardness and heat resistance

- Apply suitable coolant to reduce heat buildup

- Optimize machining speeds and feeds for material properties

- Work with experienced CNC service providers like HYCNC to handle complex jobs

What factors should be considered when choosing materials for CNC projects?

Choosing the right material depends on several factors:

- Strength requirements: How much load or stress the part will face

- Weight considerations: Especially important in aerospace or automotive parts

- Budget constraints: Some metals and composites are costlier

- Machinability: How easily the material can be cut or shaped

- Corrosion resistance: For parts exposed to harsh environments

- Application environment: Temperature, chemicals, and wear conditions

For more on material properties and choices, check our detailed guides on plastics and chromoly steel. We’re here to help you select the best material for your specific CNC machining needs.