3D Printing in the Energy Sector: Unlocking a New Era of Innovation

Are you curious about how 3D printing is reshaping the energy sector? From slashing costs to boosting sustainability, this cutting-edge technology is revolutionizing how we produce, store, and manage energy. As an industry professional, I’ve seen firsthand how additive manufacturing transforms challenges into opportunities for renewable energy, oil and gas, and beyond.

In this guide, you’ll discover the game-changing applications of 3D printing in the energy sector, uncover its benefits and hurdles, and learn how HYCNC’s expertise takes it to the next level. Ready to power up your knowledge? Let’s dive in!

Applications of 3D Printing in the Energy Sector

Wondering how 3D printing is shaking up the energy industry? It’s transforming how we build and maintain key components across various energy sources, making processes faster and more efficient.

Renewable Energy

- Solar: Custom 3D printed components for solar panels help improve efficiency by optimizing shapes and materials that traditional manufacturing can’t achieve.

- Wind: Lightweight, aerodynamic turbine blades and tower parts are now easier to produce, reducing weight while boosting performance.

- Hydro: Tailored impellers and specialized parts for hydropower systems enhance flow and durability for better energy capture.

Oil and Gas

- Rapid prototyping lets engineers create complex drilling tools and spare parts quickly.

- On-site 3D printing reduces downtime in remote locations by producing critical components when and where they’re needed.

Nuclear

- 3D printed reactor cores and safety components are emerging, enabling more precise designs.

- Precision parts built for extreme conditions improve safety and reliability in nuclear power plants.

Energy Storage

- Custom battery designs using 3D printing increase storage capacity and speed up development cycles.

- 3D printed electrolyzers support efficient hydrogen production, pushing forward clean energy storage solutions.

Across these fields, additive manufacturing is driving innovation by offering custom energy components, rapid prototyping, and quicker production to meet the complex challenges of today’s energy sector.

Benefits of 3D Printing in Energy

3D printing in the energy sector brings clear benefits that matter to businesses and communities alike.

Cost Reduction

It lowers both production and logistics costs by cutting down on material waste and shipping. This means parts can be made locally or on-site, saving time and money.

Design Flexibility

Additive manufacturing allows for complex, custom designs that traditional methods can’t handle. This helps create parts tailored exactly to performance needs, boosting overall system effectiveness.

Efficiency

Rapid prototyping speeds up development, letting teams test and improve designs faster. For example, some 3D printed solar panel components deliver up to 20% better efficiency than standard ones.

Sustainability

Printing parts layer by layer reduces material waste. Plus, 3D printing supports renewable energy projects by enabling innovative, optimized components that help move sustainable solutions forward.

On Demand Manufacturing

Being able to print parts quickly minimizes downtime, which is crucial in energy production. Instead of waiting weeks for spare parts, operators can get what they need fast—especially important in remote or hard-to-reach sites.

Challenges and Limitations of 3D Printing in the Energy Sector

While 3D printing brings many benefits, there are some challenges to keep in mind.

-

Material Constraints

Not all materials used in the energy sector can be 3D printed yet. Especially for harsh environments like oil rigs or nuclear plants, printable materials that can withstand extreme heat, pressure, or corrosion are still limited.

-

Regulatory Hurdles

The energy industry has strict safety and quality standards. Meeting these regulations with 3D printed parts takes time and rigorous testing, slowing down adoption in critical areas like nuclear and oil and gas.

-

Quality Control

Ensuring every 3D printed component is reliable and consistent is tough. Variations in printing can affect performance, so thorough inspections and testing processes are essential.

-

Scalability Challenges

Large-scale production for major energy projects is still tricky with additive manufacturing. Printing huge parts or mass quantities fast enough to meet demand remains a hurdle.

-

Initial Investment

Getting started requires high upfront costs for 3D printers, materials, and staff training. This can be a barrier, especially for smaller companies in the U.S. energy market looking to adopt this technology.

Despite these challenges, ongoing improvements are making 3D printing more viable across the energy sector every day.

Real World Examples and Innovations

3D printing is already making a solid impact in the energy sector with real-world results. Take GE’s 3D printed wind turbine components—they’ve cut costs and sped up production time significantly. This approach not only lowers expenses but also helps get turbines up and running faster, improving wind energy delivery here in the U.S.

Over at Oak Ridge National Laboratory (ORNL), they’re pushing the limits with 3D printed nuclear reactor parts. These precision components boost safety and efficiency, handling extreme conditions better than traditional parts. It’s a big step forward for nuclear energy, showing how additive manufacturing can enhance reliability in critical infrastructure.

Now we’re also seeing new materials like PEKK thermoplastics gaining traction. These advanced materials handle tough environments and high temperatures well, making them perfect for energy applications. Plus, large scale 3D printing is evolving fast, allowing bigger and more complex parts to be made on demand. These innovations are changing the game, giving U.S. energy companies fresh tools to improve efficiency and sustainability.

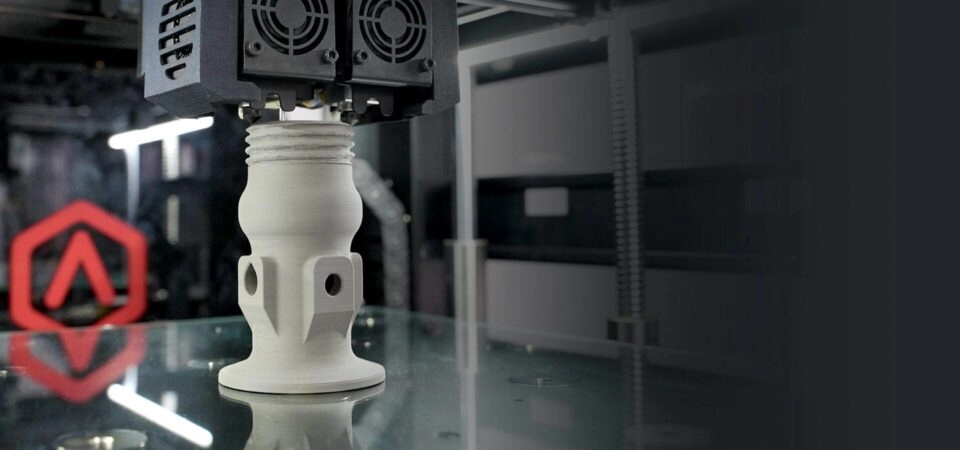

How HYCNC Enhances 3D Printing for Energy

HYCNC takes 3D printing in the energy sector to the next level by combining precision CNC machining with additive manufacturing. This hybrid approach ensures parts not only meet strict tolerances but also have the durability needed for tough energy applications. Whether it’s finishing 3D printed components or adding complex details, CNC processing from HYCNC guarantees high-quality results.

We offer custom solutions specifically designed for the energy industry, including tailored parts for solar panels, wind turbines, and oil and gas equipment. Our deep experience working with energy manufacturers in the U.S. means we understand the unique demands of this market and can deliver reliable, fit-for-purpose components.

Sustainability is also a priority for us. By supporting eco-friendly energy innovations, HYCNC helps reduce waste and promote greener solutions across renewable and traditional energy sectors. Our combined 3D printing and CNC expertise streamlines production and supports cutting-edge energy projects across the country.

The Future of 3D Printing in the Energy Sector

The future of 3D printing in the energy sector looks promising, with the market expected to hit $17 billion by 2032. As demand grows, innovations like new advanced materials, faster printing methods, and the integration of AI sensors will push the technology even further. These advances will help create more efficient, reliable, and smarter energy components.

Sustainability is a big part of this future. 3D printing supports cleaner energy by reducing waste and enabling custom parts for renewables like solar and wind. This aligns perfectly with the U.S. push toward greener, more efficient energy solutions.

Collaboration is key to making the most of these technologies. Industry leaders, academic institutions, and service providers like HYCNC work together to combine precision CNC machining with 3D printing. This teamwork helps develop tailored solutions for solar, wind, oil and gas, and more, speeding up innovation while maintaining quality and durability.

In short, 3D printing will be a driving force behind a smarter, more sustainable energy landscape — and regional partners like HYCNC are ready to help businesses tap into this potential.