Understanding 3D Print Strength

When you think about strong 3D prints, it’s more than just using tough materials. Strength in 3D printing depends on several factors coming together—how well the layers stick, the print’s internal structure, and the overall design. What makes a 3D print truly strong is the combination of good material choice, precise printer settings, and smart design decisions.

Common weaknesses in 3D prints often come from poor layer adhesion, gaps inside the print, or using materials that can’t handle stress well. These weaknesses can cause your print to crack, warp, or break under pressure.

Why does this matter? If you want your 3D prints to last, perform well, or handle real-world applications, understanding what impacts strength is key. Whether you’re making functional parts or prototypes, building durability into your prints saves time, money, and frustration down the road.

Choosing the Right Materials for Strong 3D Prints

Picking the right material is a big deal when you want strong 3D prints. Different materials offer different durability levels, flexibility, and printability. Using the right filament can make a huge difference in how your final print performs.

Popular Materials

- PLA: Easy to print but less durable, best for prototypes and decorative parts.

- ABS: Stronger and more heat resistant, great for functional parts but needs good ventilation.

- PETG: Combines strength and flexibility, with good layer adhesion and chemical resistance.

- Nylon: Very durable and flexible, excellent for parts that need toughness and wear resistance.

- Composite Filaments: Filaments mixed with carbon fiber or glass fiber boost strength and stiffness, perfect for high-performance prints.

Material Selection Tips

- Choose a material that fits your project’s strength needs and environmental conditions.

- Look for filaments with good layer adhesion and impact resistance for tough prints.

- Consider how easy it is to print the material—some strong filaments require precise temperature control.

- Check your printer’s compatibility with specialty materials before buying.

HYCNC’s Role

At HYCNC, we understand strong 3D printing materials and offer expert guidance to match the right filament with your project. Our CNC machining services also complement 3D prints by improving accuracy and adding durability through precise post-processing. This helps you get the strongest, most reliable parts possible right here in the U.S.

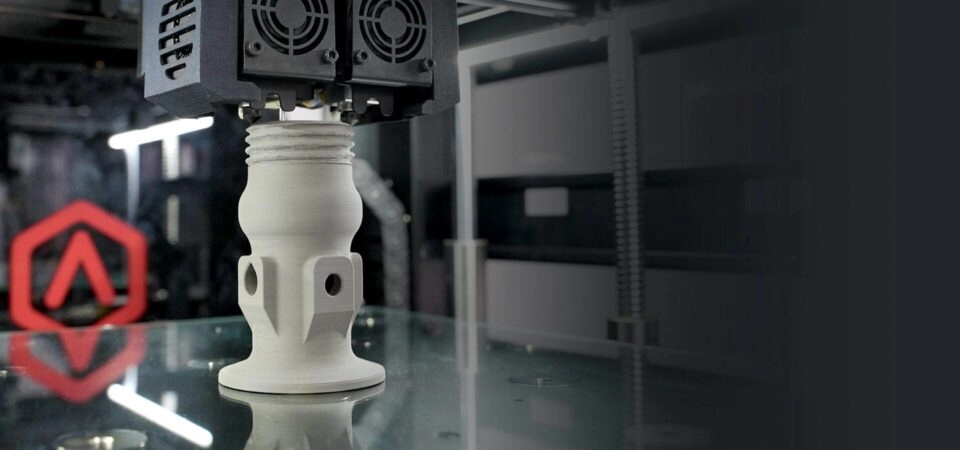

Optimizing 3D Printer Settings

Getting the right 3D printer settings is key to making strong 3D prints. Small tweaks can boost your print durability and layer adhesion. Here’s what to focus on:

Layer Height

Keep it moderate. Too thin, and the print takes forever; too thick, and layers won’t bond well. A layer height between 0.1mm and 0.2mm usually works best for strength.

Infill Density

Higher infill means stronger parts. Aim for 20-50% depending on how tough you need your print. Denser infill patterns like grid or cubic give better strength without wasting too much material.

Print Temperature

Set your nozzle temperature right for the filament you use. Too low can cause weak bonding between layers; too high might cause stringing or warping. Check your filament specs but don’t be afraid to experiment a bit for better layer adhesion.

Print Speed

Slower print speeds improve layer bonding and print quality. Try to keep speed around 40-60mm/s for strong results, especially with tricky materials.

Cooling Settings

Cooling helps with detail but can weaken layer adhesion if overdone. For strength, reduce fan speed during the first few layers to let layers fuse better. After that, moderate cooling keeps print quality without sacrificing strength.

Fine-tuning these settings really helps make stronger 3D prints that last.

Design Tips for Stronger 3D Prints

Getting the design right is a huge step toward making strong 3D prints. Here are some straightforward tips to boost your print’s durability:

Wall Thickness

Thicker walls mean more strength. A minimum of 2-3mm is a good start, but increase it based on the part’s purpose. Thin walls can snap under stress, so don’t cut corners here.

Infill Patterns

The infill pattern affects how your print handles pressure. Patterns like grid, cubic, or gyroid distribute stress more evenly, making your part tougher. Also, raise the infill density if you want strength over weight savings.

Orientation

How you position your print on the bed changes its strength. Layers bond strongest in the direction they’re printed, so orient parts so the layers align with expected stress points. This reduces weak spots from layer separation.

Fillets and Chamfers

Sharp corners can cause stress concentrations and lead to cracks. Adding fillets (rounded edges) or chamfers (beveled edges) spreads out stress, improving durability.

Software Tools

Use design software with features for strength optimization. Many programs can analyze stress zones and suggest design tweaks like thicker walls or better infill patterns. This helps catch weak spots before printing.

Applying these design tips can make a noticeable difference in your 3D print durability without adding much complexity. For detailed guides on prototype making and design, check out our post on how to make a prototype.

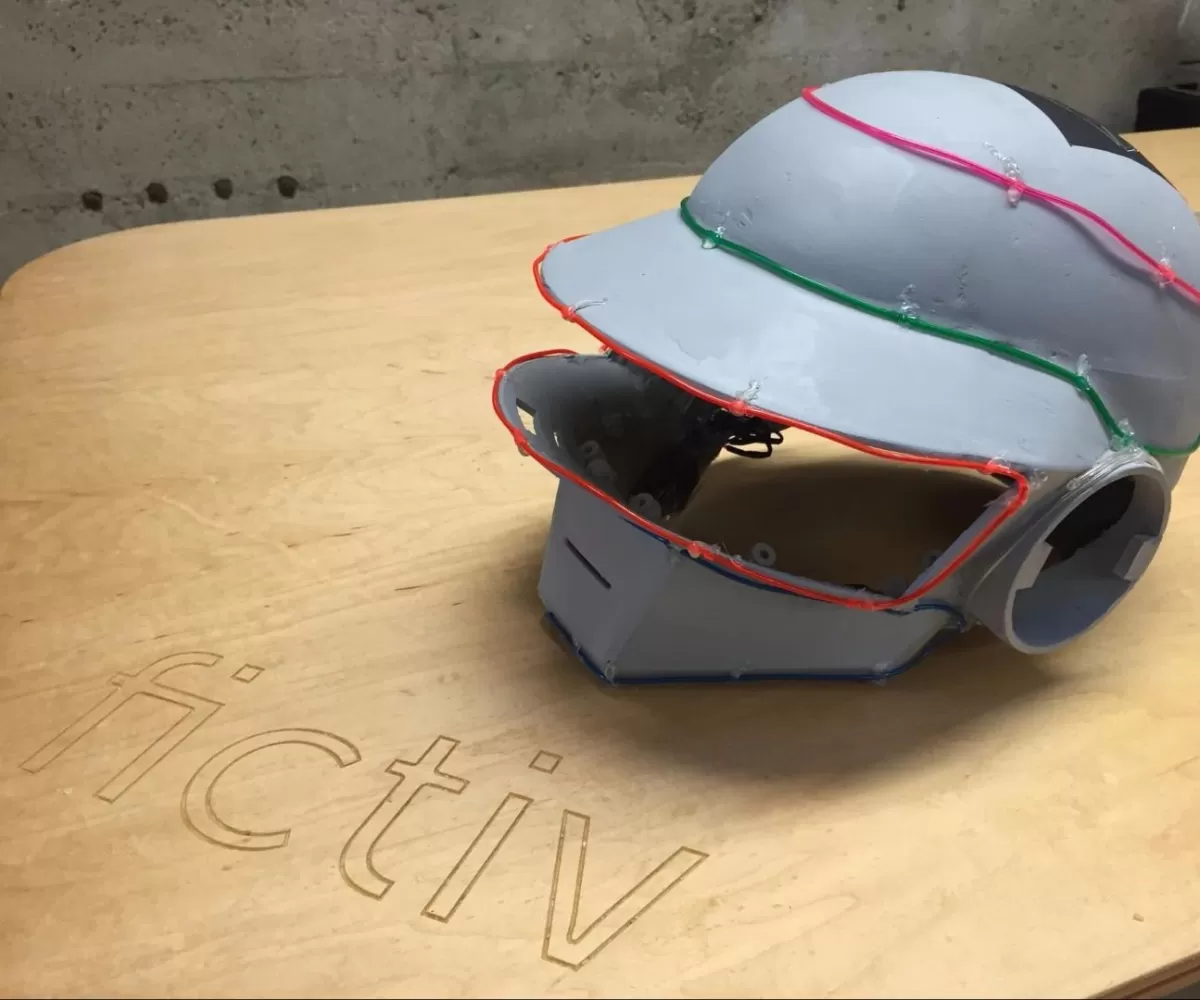

Post-Processing Techniques for Enhanced Strength

Post-processing can seriously boost the durability of your 3D prints. Here are some top techniques to make your prints stronger and longer-lasting.

Annealing

Annealing involves heating your print to a specific temperature and then cooling it slowly. This process helps improve layer adhesion and reduces internal stresses. It’s especially effective for materials like PLA and PETG, making the final product tougher and less prone to cracking.

Sanding and Smoothing

Sanding removes rough surfaces and small imperfections that can weaken your print. Smoother surfaces mean better layer bonding and less chance of stress points. After sanding, you can also use smoothing techniques like vapor smoothing (for ABS) to seal layers tightly.

Epoxy Coating

Applying an epoxy resin coating adds a tough outer shell to your print. This not only improves strength but also water resistance and overall durability. Epoxy is great for parts exposed to wear and tear or harsh environments.

HYCNC’s CNC Post-Processing

HYCNC takes your 3D prints to the next level with precision CNC post-processing. They can machine your prints to exact specifications, improve surface finish, and reinforce critical areas. If you need professional-grade durability and fine detail, HYCNC’s CNC services are a solid choice for enhancing your 3D print durability.

Common Mistakes to Avoid

When aiming for strong 3D prints, certain mistakes can seriously weaken your results. Here are some common pitfalls to watch out for:

Under-Extrusion

This happens when your printer doesn’t push out enough filament. It leads to gaps, weak layer adhesion, and fragile prints. Always check your extrusion settings and keep your nozzle clean to avoid this.

Improper Bed Adhesion

If your print doesn’t stick well to the build plate, layers can shift or warp, ruining strength. Use the right bed surface, apply adhesives if needed, and make sure your bed is level before starting.

Ignoring Material Limits

Every material has its strengths and weaknesses. Trying to push a filament beyond its limits—like printing flexible parts with brittle PLA—can cause cracking or failure. Choose materials that match your project’s durability needs.

Overlooking Design Flaws

Poor design choices hurt print strength. Thin walls, sharp corners, or weak infill patterns can lead to breakage. Spend time refining your design for better layer adhesion and overall durability.

Avoiding these mistakes helps you get the most out of your 3D print durability and ensures your finished parts last longer in real-world use.

How HYCNC Enhances Your 3D Printing Workflow

CNC Integration

At HYCNC, we understand that strong 3D prints often need precise finishing touches to reach their full potential. That’s why we offer seamless CNC machining services that complement your 3D printing projects. By combining 3D printing with CNC post-processing, we help improve part accuracy, surface finish, and overall durability. This integration means you get the best of both worlds: the flexibility of 3D printing and the precision of CNC machining.

Why Choose HYCNC

Choosing HYCNC means working with a team dedicated to boosting your print durability and quality. We provide expert advice on material selection, printer settings, and post-processing techniques tailored to your needs. Plus, our CNC services efficiently refine your prints—whether it’s smoothing surfaces, adding custom details, or strengthening critical areas. Our local US-based support ensures prompt delivery and responsive customer service, so your prototypes and production parts meet deadlines every time.

Call to Action

Ready to make your 3D prints stronger and more precise? Learn how HYCNC can streamline your workflow from design to finished product. Visit our blog to discover how to make a prototype and start optimizing your 3D printing and CNC machining process today. Contact us to discuss your project and take the first step toward stronger, more reliable 3D prints.