What is 3D Printing and Why It Matters

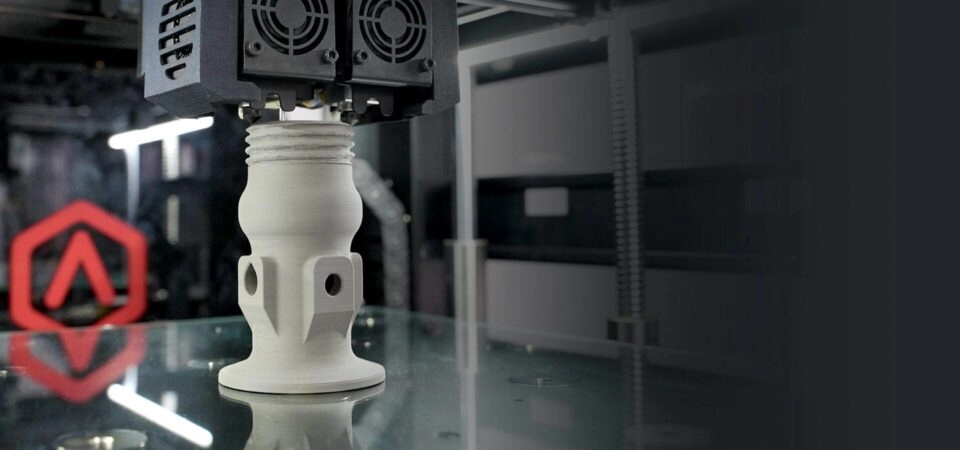

3D printing, also known as additive manufacturing, is a process where objects are created layer by layer from a digital design. Unlike traditional manufacturing that often cuts away material, 3D printing builds parts by adding material—whether plastic, metal, or other substances—precisely where it’s needed. This method unlocks huge advantages across industries.

The core benefits of 3D printing include:

- Design flexibility: Complex shapes and custom parts that were impossible or too costly before can now be produced easily.

- Rapid prototyping: Quickly move from concept to physical model, speeding up development cycles and innovation.

- Cost efficiency: Less material waste and lower tooling costs make small production runs more affordable.

- Customization: Tailor products to individual needs without retooling entire production lines.

- Faster time-to-market: Get products from design to delivery more quickly with streamlined manufacturing.

These advantages have made 3D printing a game changer in multiple industries by improving how products are designed, made, and delivered.

Key Industries Using 3D Printing

Aerospace

3D printing in aerospace helps produce lightweight, complex parts that reduce fuel consumption and boost performance. Custom components like turbine blades and small engine parts are made faster and with less waste. For example, companies like Boeing use additive manufacturing to create fuel nozzles that are stronger and lighter than traditional parts.

Automotive

The automotive industry uses 3D printing for rapid prototyping and creating custom parts. It speeds up design testing and allows for producing limited runs of specialty components. Brands like Ford and Tesla use it to develop car models and manufacture lightweight parts, improving fuel efficiency and reducing production costs.

Healthcare and Medical

Medical 3D printing creates custom prosthetics, implants, and surgical tools tailored to individual patients. It supports precision in complex surgeries and faster production of medical devices. Hospitals across the U.S. use 3D printing for dental implants and even bioprinting tissues in research.

Architecture and Construction

3D printing in construction allows building intricate architectural models and actual structures with less material waste. It supports rapid prototyping of designs and can print components like walls and facades. Some U.S. firms use large-scale 3D printing to create parts for affordable housing projects quickly and efficiently.

Manufacturing

Industrial 3D printing enhances manufacturing by enabling on-demand production and custom tooling. It reduces inventory needs and shortens supply chains. Companies leverage it to create jigs, fixtures, and replacement parts that are reliable and cost-effective.

Robotics

In robotics, 3D printing lets engineers prototype and build lightweight components and complex assemblies quickly. Custom parts for drones and automation equipment are common examples. This helps speed up product development and lowers the cost of testing new robotic designs.

Fashion and Consumer Goods

3D printing in fashion brings originality to jewelry, eyewear, and clothing by enabling custom fits and unique designs. Consumer goods benefit from personalized products and faster prototyping. Brands are using it to create limited-edition pieces and one-of-a-kind accessories quickly.

Oil and Gas

The oil and gas industry applies 3D printing to produce durable, custom parts for equipment used in harsh environments. It helps reduce downtime by supplying replacement parts faster. Companies print valves, connectors, and other critical components tailored to specific needs.

Entertainment

3D printing powers the entertainment industry by creating detailed props, costumes, and set pieces efficiently. It allows for quick iteration and custom designs that would be costly with traditional methods. Studios use 3D printing to bring unique visual effects and realistic models to life.

Education

In education, 3D printing provides hands-on learning tools and enhances STEM programs by letting students design and create prototypes. Schools use it to teach engineering, design, and technology skills with real-world applications. It’s a great way to make learning interactive and engaging.

Benefits of 3D Printing Across Industries

3D printing brings solid benefits that many industries appreciate. First up, cost savings and reduced waste. Unlike traditional manufacturing that cuts away material, 3D printing only uses what’s needed. This means less leftover scrap and lower costs, especially for custom or small-batch parts.

Another big advantage is design flexibility and customization. With additive manufacturing applications, companies can create complex shapes or tailor products specifically for each customer without extra tooling or setup time.

Faster time-to-market is a game changer as well. Prototyping becomes quicker, so products reach the market sooner, improving competitive edge across sectors like automotive and aerospace.

Sustainability benefits are increasingly important. 3D printing often consumes less energy and materials, helping businesses meet eco-friendly goals.

Finally, the integration of 3D printing with CNC machining combines the best of both worlds. This hybrid approach enhances precision and finish, allowing industries to produce high-quality parts efficiently. This is especially valuable for custom 3D printed parts needing tight tolerances.

Together, these benefits make 3D printing a smart choice for industries looking to innovate and save.

Challenges and Future Trends in 3D Printing

While 3D printing is transforming many industries, it still faces some challenges. One big hurdle is the limited range of materials suitable for 3D printing. Many industries need stronger, more durable, or heat-resistant materials that are still hard to print reliably. Another challenge is the skilled workforce—finding technicians and engineers who really understand both 3D printing and CNC machining can be tough.

On the bright side, emerging trends are opening new doors. Bioprinting is making waves in healthcare by printing tissues and organs for research and transplant. Automation is making 3D printing faster and more efficient, especially when paired with CNC machining for finishing and precision. Plus, new materials, like advanced composites and metal alloys, are expanding what 3D printing can do.

Looking ahead, the technology is expected to grow into new industries like energy, education, and even food production. Businesses that adopt 3D printing early and combine it with traditional manufacturing methods will gain a big edge.

For more insight into integrating 3D printing with CNC, check out our article on CNC prototyping vs 3D printing.

Why Choose HYCNC for 3D Printing and CNC Solutions

At HYCNC, we specialize in combining 3D printing with CNC machining to deliver precise, high-quality parts that meet your exact needs. Our expertise allows us to offer custom solutions across a wide range of industries—from aerospace and automotive to healthcare and manufacturing. Whether you need rapid prototyping, complex custom parts, or small-batch production, we tailor our services to fit your project requirements.

Choosing HYCNC means partnering with a trusted local provider that understands the unique demands of U.S. businesses and can help you leverage the best of additive manufacturing and CNC technologies. Contact us today to discuss how our 3D printing and CNC solutions can drive your project forward efficiently and cost-effectively.