Are you curious about how 3D printing for consumer products is reshaping the way we create everyday goods? From custom sneakers to personalized phone cases, additive manufacturing is revolutionizing the consumer goods industry with unmatched flexibility and speed. As a business owner or designer, I’ve seen firsthand how 3D printing transforms ideas into reality, cutting costs and sparking innovation. In this guide, you’ll discover the game-changing benefits, real-world applications, and how HYCNC’s cutting-edge 3D printing solutions can bring your vision to life. Let’s explore the future of consumer product design!

What Is 3D Printing for Consumer Products

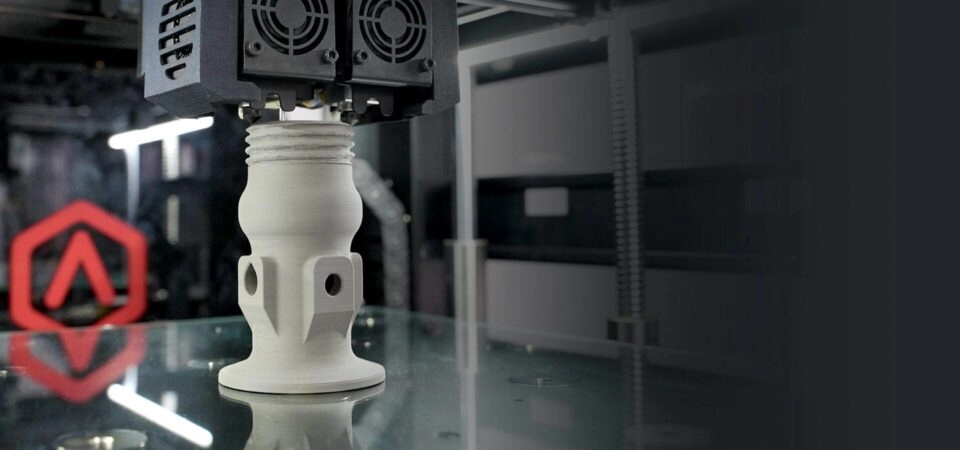

Wondering what 3D printing for consumer products really means? Simply put, it’s a manufacturing method where objects are built layer by layer from digital designs. Unlike traditional mass production, this process—also known as additive manufacturing—lets you create items directly from materials like plastics, resins, metals, and composites.

This technology is changing the way we make everyday consumer goods. You’ll find 3D printing in everything from custom footwear and stylish eyewear to personalized electronics and unique jewelry pieces. It’s perfect for creating one-of-a-kind items or small batches without the need for expensive molds or tooling.

There are several key 3D printing methods used for consumer products:

- Fused Filament Fabrication (FFF) – melts and extrudes plastic filament to build objects layer by layer. Great for prototyping and durable consumer parts.

- Selective Laser Sintering (SLS) – uses a laser to fuse powdered materials like nylon, offering strong, complex shapes perfect for performance items like footwear and gadgets.

- Digital Light Processing (DLP) – cures liquid resin with light to produce extremely detailed and smooth finished pieces, ideal for jewelry and eyewear.

These technologies open up new possibilities for customizing and producing consumer goods faster and more efficiently than ever before.

Benefits of 3D Printing for Consumer Products

3D printing brings real advantages to making consumer goods. One big win is customization—it lets you create personalized products like eyewear or jewelry without the usual high costs. Whether it’s a unique design or a perfect fit, 3D printing makes it easy to deliver exactly what customers want.

Speed is another key benefit. With rapid prototyping and on-demand production, brands can get products from idea to market much faster than traditional manufacturing. This means quicker launches and the ability to respond to trends or customer feedback quickly.

When it comes to costs, 3D printing helps cut expenses by minimizing tooling costs—there’s no need for expensive molds or setups. It’s flexible enough to handle small runs or larger batches while reducing waste, making it a cost-efficient choice for different production volumes.

Sustainability also plays a big role. 3D printing produces less material waste and supports localized production, which lowers shipping emissions and helps reduce the overall environmental footprint.

Finally, 3D printing allows for complex designs that are otherwise impossible or very expensive to make with traditional methods. Intricate shapes and fine details open new doors for innovation in consumer products, from futuristic footwear to unique electronics cases.

Real-World Applications of 3D Printing in Consumer Goods

3D printing has made a real difference across various consumer product categories here in the U.S. Let’s look at some popular industries where it’s shaking things up.

Fashion and Accessories

From lightweight 3D printed eyewear frames to custom footwear and unique jewelry, 3D printing lets designers create personalized, stylish pieces fast. Consumers can get exactly what fits their style and size without the usual wait or cost.

Electronics

Custom 3D printed casings for smartphones, wearables, and speakers are becoming common. These cases are tailored to fit perfectly and can include personalized designs or enhanced functionality, all without the expense of traditional tooling.

Home Goods

Furniture, decor, personalized kitchen tools, and gadgets are perfect for 3D printing. This tech allows for intricate designs and on-demand production, meaning you can have customized home products that match your needs and space.

Sporting Goods

Bike frames, helmets, and golf equipment made with 3D printing offer lightweight strength and custom fits. This helps athletes and hobbyists get gear designed exactly for their body and playing style.

Case Study

Consider a hypothetical project by HYCNC, a CNC and 3D printing service provider. They create a custom 3D printed phone case tailored to a client’s unique style and phone model. The case delivers precise fit, durability, and unique design elements, combining HYCNC’s CNC precision with flexible additive manufacturing. This highlights how HYCNC helps bring personalized consumer product ideas to life quickly and affordably.

How HYCNC Enhances 3D Printing for Consumer Products

At HYCNC, we combine years of CNC machining expertise with advanced 3D printing to deliver top-quality consumer products. This blend helps us achieve high precision and outstanding detail, making your designs come to life exactly as planned.

Services Tailored to Your Needs

We don’t just print – we offer full support from design consultation to prototyping and final production. Whether you’re creating custom footwear, eyewear, or electronics casings, HYCNC guides you through the process to ensure your product fits your vision and market demands.

Wide Range of Materials

Our material selection covers polymers, metals, and composites, providing flexibility to create durable, functional, and stylish consumer goods. This variety supports customization without compromising quality or performance.

Innovation Through Technology

By combining CNC precision with the freedom of 3D printing, we unlock complex designs that traditional manufacturing can’t handle. This means faster turnaround times and more creative options for your product line.

Get in Touch for Custom 3D Printing Solutions

Ready to take your consumer products to the next level? Contact HYCNC today for tailored 3D printing solutions designed to meet the unique needs of the U.S. market. Let’s create something exceptional together.

Challenges and Solutions in 3D Printing for Consumer Products

3D printing for consumer products is growing fast, but it still faces some challenges. Cost is a big one—high-quality printers and materials can be pricey, especially for small businesses or startups. Material options, while improving, sometimes limit product durability or finish, making it tough to match traditional manufacturing quality. Plus, getting used to design software for 3D printing isn’t always easy, with a learning curve that can slow down production for new users.

At HYCNC, we tackle these challenges head-on by offering affordable 3D printing services that don’t compromise on quality. Our expert support helps you navigate design software and optimize your product for printing, saving you time and hassle. We also use advanced tools that combine CNC precision with 3D printing flexibility, expanding what’s possible for material choices and product detail.

Looking ahead, the future of 3D printing for consumer goods looks promising. Material innovations are unlocking stronger, more diverse options, while industry forecasts predict steady market growth. This means more opportunities for businesses and consumers in the U.S. to enjoy personalized, sustainable, and cost-effective products made with 3D printing.