Are you curious about investment casting and how it creates precision parts for industries like aerospace and automotive? Choosing the right manufacturing process can transform your project’s quality and efficiency.

As experts in precision casting and CNC machining, we at HYCNC understand the power of investment casting to deliver intricate, high-quality components. In this guide, you’ll uncover what investment casting is, its step-by-step process, and why it’s a game-changer for complex metal parts.

Let’s dive into the world of lost-wax casting and explore how it can elevate your next project!

What is Investment Casting

Investment casting, also known as lost-wax casting, is a precision casting process that creates metal parts by forming a ceramic mold around a wax pattern. Once the mold hardens, the wax is melted away, leaving a cavity for molten metal to be poured in. This method is prized for its ability to produce complex shapes with excellent surface finishes and tight dimensional tolerances.

Historically, investment casting has been used for thousands of years, dating back to ancient civilizations such as the Egyptians and Chinese, who used wax molds to craft intricate jewelry and tools. Over time, the process has evolved with modern materials and technologies but still follows the same fundamental principle of wax pattern manufacturing and ceramic mold casting.

Key characteristics of investment casting include:

- High precision and accuracy for complex metal parts

- Ability to replicate fine details and thin walls

- Smooth surfaces that reduce the need for secondary machining

- Versatility in materials ranging from stainless steel to exotic alloys

This method stands out in the high-precision manufacturing landscape, making it a go-to choice for industries like aerospace, medical, and automotive sectors seeking reliable and detailed components.

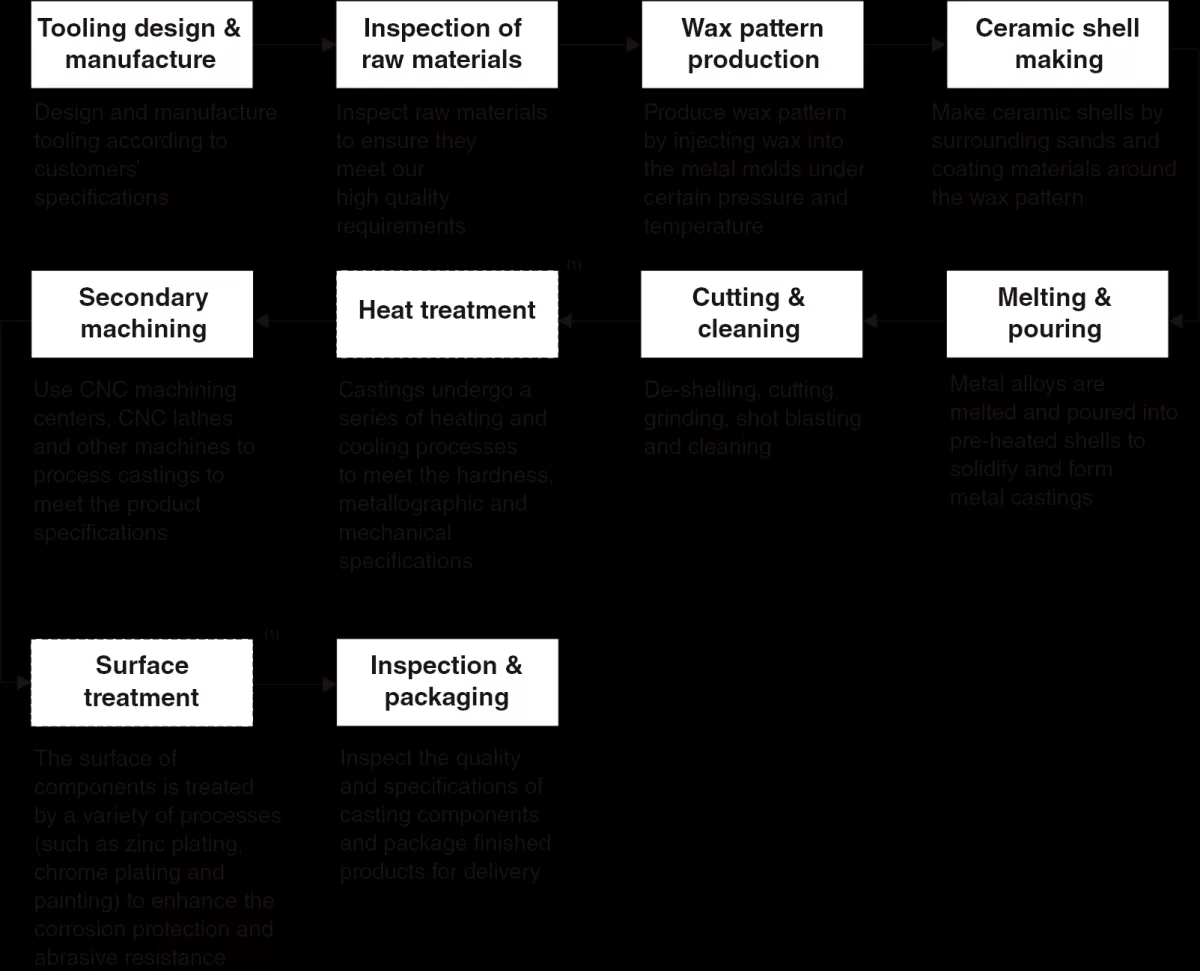

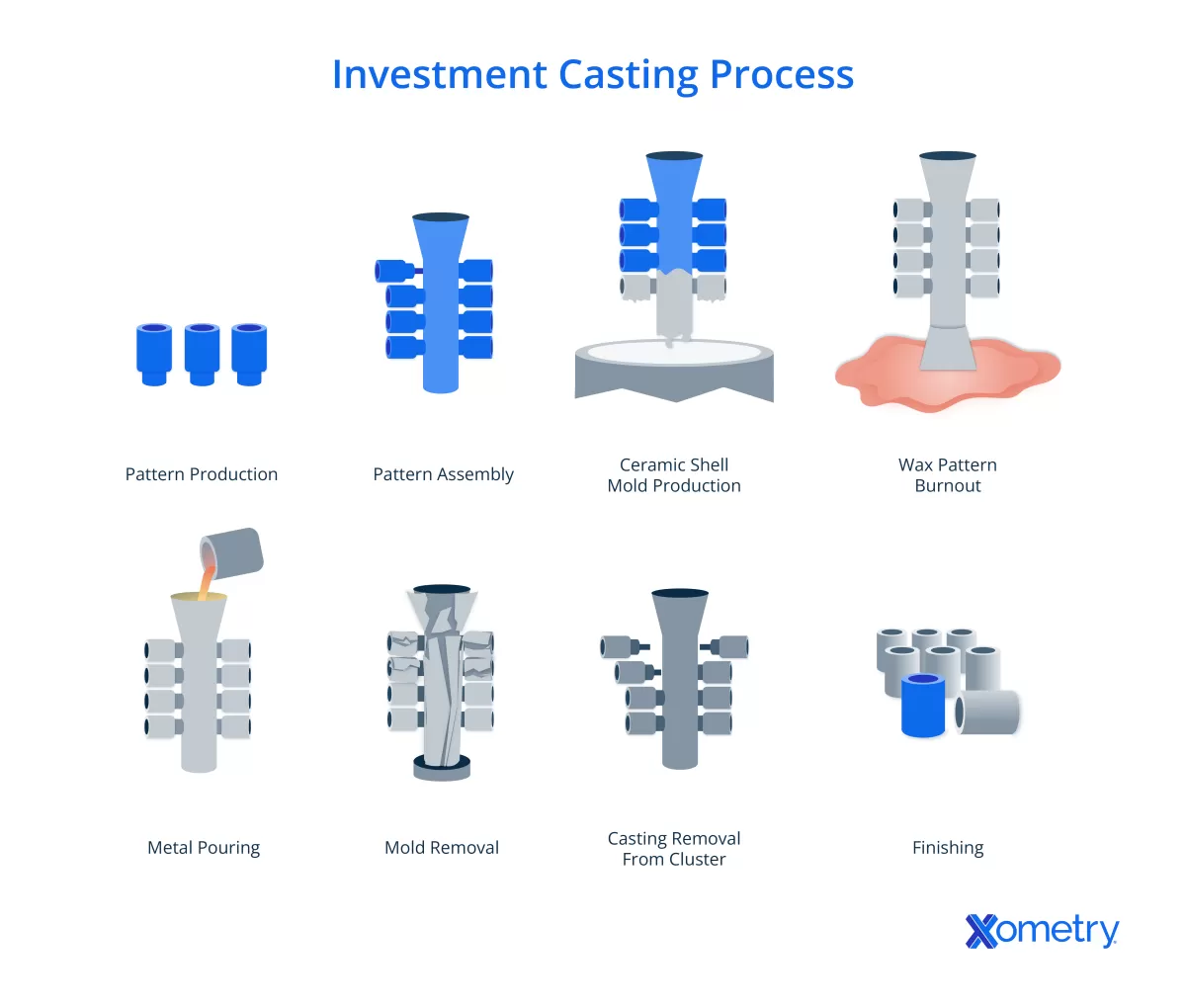

The Investment Casting Process Step by Step

Investment casting, also known as lost-wax casting, follows a precise series of steps to produce high-quality metal parts. Here’s how it works:

-

Creating the wax pattern

First, a wax model of the final part is made. This wax pattern is an exact copy, capturing all the fine details needed for the metal piece.

-

Assembling the wax tree

Several wax patterns are attached to a central wax sprue, forming what’s called a “wax tree.” This setup allows multiple parts to be cast in one go.

-

Building the ceramic shell

The wax tree is dipped repeatedly in a ceramic slurry, then coated with fine sand. This process is repeated to build a thick ceramic shell around the wax models.

-

Wax removal

Once the ceramic mold is hardened, it’s heated to melt and drain out the wax, leaving a hollow ceramic shell ready for metal casting.

-

Metal pouring

Molten metal is poured into the hot ceramic mold, filling the space left by the wax. This step demands precision to avoid defects.

-

Cooling and shell removal

After the metal cools and solidifies, the ceramic shell is broken away carefully to reveal the cast metal parts.

-

Finishing and inspection

Finally, the parts are cut from the sprue, cleaned, and inspected for quality. Any necessary finishing touches, like grinding or machining, are done to meet specifications.

This step-by-step investment casting process ensures complex shapes with fine details and excellent surface finish, making it popular for precision casting needs.

Benefits of Investment Casting

Investment casting offers several clear advantages that make it a go-to process for many manufacturers. Here’s why it stands out:

-

Superior Dimensional Accuracy and Tight Tolerances

This process delivers parts with excellent precision, often within thousandths of an inch. That means less guesswork and tighter fits for your components.

-

Excellent Surface Finish Reducing Secondary Machining

Because the ceramic mold is incredibly smooth, the final metal parts come out with a great surface finish. This reduces the need for extra machining or polishing, saving time and cost.

-

Ability to Cast Complex Geometries and Thin Walls

Investment casting handles detailed, intricate designs that other methods struggle with. Thin walls and complex shapes come out cleanly, making it ideal for sophisticated parts.

-

Material Versatility

From stainless steel to aluminum, titanium, and even superalloys, investment casting can work with a wide range of metals to meet different strength and performance needs.

-

Cost Effective for Small to Medium Runs

While initial tooling costs may be higher, the process excels in low to medium volume production where high precision is required, offering good cost efficiency compared to other high-precision methods.

These benefits make investment casting a solid choice for industries requiring accurate, detailed metal parts without the extra fuss.

Applications of Investment Casting

Investment casting is widely used in industries where precision and complex designs matter. Here are some common applications:

- Aerospace components: The process allows for making lightweight, strong parts with intricate shapes that meet strict tolerances needed in aircraft engines, turbines, and structural parts.

- Automotive parts: From engine components to transmission parts, investment casting helps create durable and precise metal parts that improve vehicle performance.

- Medical implants and instruments: Thanks to its ability to produce biocompatible materials with exact detail, investment casting is great for surgical tools, joint replacements, and other medical devices.

- Industrial machinery components: Investment casting delivers high-strength parts with complex geometries for pumps, valves, and heavy equipment, ensuring reliability and longevity.

- Enhancing CNC machining industries: Because investment casting produces near-net-shape parts with excellent surface finishes, it reduces the need for extensive CNC machining, saving time and cost in manufacturing.

This versatility makes investment casting a preferred choice for many U.S. manufacturers looking for quality, precision, and efficiency in metal parts production. For more on precision manufacturing techniques, check out our guide on what is CNC machining.

Investment Casting vs Other Methods

When comparing investment casting to other metal casting methods like sand casting and die casting, each has its strengths, but investment casting shines in precision and detail.

Comparison with Sand Casting

- Accuracy: Investment casting offers far superior dimensional accuracy and finer surface finishes than sand casting, which can be rough and less precise.

- Complexity: Sand casting struggles with intricate shapes and thin walls, whereas investment casting easily handles complex metal parts with fine details.

- Surface Finish: Investment casting produces smoother surfaces, which means less finishing work is needed. Sand casting often requires more machining afterward.

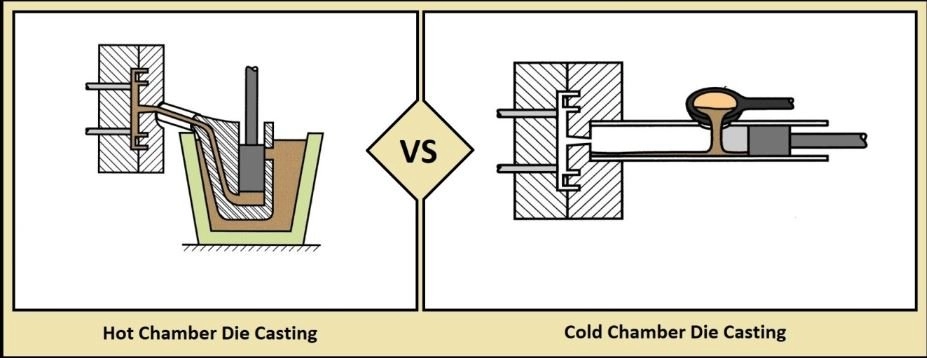

Comparison with Die Casting

- Material Flexibility: Die casting mostly works with non-ferrous metals like aluminum, zinc, and magnesium. Investment casting supports a broader range, including high-temperature alloys often needed for aerospace or medical parts.

- Tooling Costs and Runs: Die casting tooling is expensive but efficient for large production runs. Investment casting has higher initial tooling costs but becomes cost-effective for small to medium volumes.

- Precision: Investment casting allows tighter tolerances and complex geometries that die casting might not handle well.

Why Investment Casting Suits Precision CNC Applications

Investment casting creates near-net-shape parts with tight tolerances and excellent surface quality. This means CNC machining after casting requires minimal material removal, saving time and cost. The combination of high-precision manufacturing through investment casting and CNC machining integration ensures parts meet demanding specifications critical in aerospace, medical, and complex engineering sectors.

For more on machining methods that complement casting, check out our guide on what is CNC machining.

In sum, investment casting stands out when you need detailed, precise, and complex metal components, especially when paired with CNC machining for finishing.

Challenges and Limitations of Investment Casting

Investment casting is great for precision and complex parts, but it does come with some challenges:

-

Higher initial tooling costs: Making the wax patterns and ceramic molds requires detailed tooling, which can be expensive upfront. This cost can be a barrier for very small or one-off projects.

-

Longer lead times: The multi-step process—from wax pattern creation to finishing—takes more time than some other casting methods, which means longer wait times for parts.

-

Size constraints: Investment casting works best for small to medium-sized parts. Large pieces may be difficult or costly to produce due to the mold and shell limitations.

Luckily, many of these downsides can be eased with advances in technology:

- 3D printing helps speed up wax pattern manufacturing, cutting lead times and reducing tooling costs.

- Automation in ceramic shell building and wax removal improves consistency and efficiency.

- New materials extend the size range and strength of ceramic molds.

By adopting these modern technologies, investment casting remains a cost-effective and precise option for many industries, especially when paired with CNC machining. For more on complementary processes, check out our post on what is CNC machining.

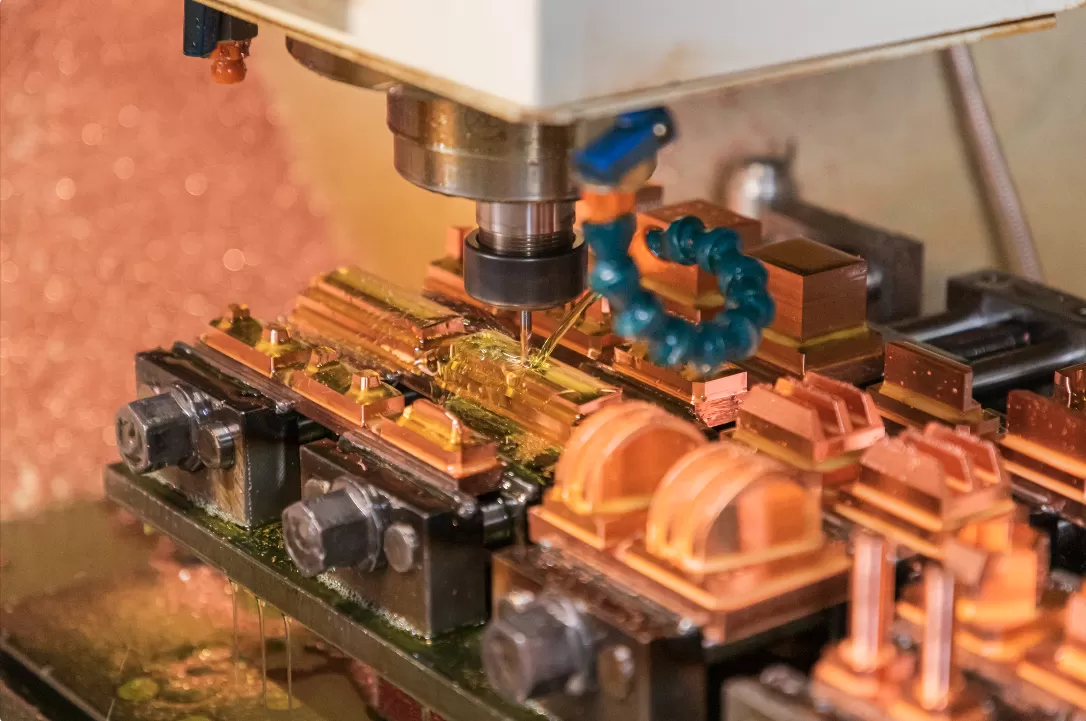

Why Choose HYCNC for Investment Casting

When it comes to investment casting, HYCNC stands out with deep expertise in both precision casting and CNC machining. We understand the importance of tight tolerances and complex metal parts, so we make sure every piece meets demanding standards.

Our state-of-the-art facilities use advanced automation to ensure consistency and speed across every step of the process. This setup allows us to handle everything—from wax pattern manufacturing to final finishing—with accuracy and efficiency.

We also believe every industry and project is unique. That’s why we offer customized solutions tailored to your specific needs, whether you’re in aerospace, automotive, or medical fields.

Quality is not just a goal; it’s a commitment. We carefully inspect every casting before it leaves our shop, ensuring you get reliable parts ready for your production line or CNC machining integration.

If you want to discuss how HYCNC can deliver precise, cost-effective investment casting solutions to fit your project, contact us for tailored solutions designed around your requirements.

FAQs About Investment Casting

What materials can you use in investment casting?

You can cast a wide range of metals, including stainless steel, aluminum, brass, bronze, and even some superalloys. This makes investment casting versatile for different industries and needs.

How does investment casting compare to CNC machining alone?

Investment casting creates complex shapes and thin walls that are tough to machine from raw metal. It’s ideal for getting close to the final shape, which then requires less CNC machining, saving time and cost while maintaining high precision.

Which industries benefit most from investment casting?

Aerospace, automotive, medical, and industrial machinery sectors rely heavily on investment casting. These fields demand high-precision parts with excellent surface finishes and tight tolerances, which this process delivers.

How long does the investment casting process take?

Lead times vary but expect several weeks for initial tooling and pattern preparation. Production cycles are longer than die casting but shorter than many custom methods, especially with modern automation.

Why is it called lost-wax casting?

The name comes from the wax pattern being “lost” or melted away during the process, leaving a cavity in the ceramic mold for metal pouring. It’s the traditional name tied to this precision casting technique.