What is Zinc Die Casting

Zinc die casting is a manufacturing process where molten zinc alloys are injected into steel molds under high pressure to create precise, durable parts. This technique allows for producing complex shapes with tight tolerances and smooth finishes, making it ideal for mass production.

Common zinc alloys used in this process include Zamak 3, Zamak 5, and Zamak 7. These alloys blend zinc with aluminum, magnesium, and copper, giving parts excellent strength, corrosion resistance, and ease of casting. Zinc alloys have a low melting point (around 787°F or 419°C), which speeds up production and reduces energy use compared to other metals. Because of their versatility and reliability, zinc alloy automotive parts are widely favored for precision die casting in the automotive industry.

Why Zinc Die Casting is Ideal for the Automotive Industry

Zinc die casting is a great fit for automotive manufacturing because it offers a strong combination of strength, precision, and cost savings. Zinc components are known for their high strength and durability, making them excellent choices for parts that need to withstand wear and tear over time. Whether it’s support brackets or load-bearing pieces, zinc alloys deliver longevity that drivers can rely on.

When it comes to precision, zinc die casting shines with its ability to produce parts with tight tolerances and fine detail. This means components fit better and perform more consistently in vehicles, which is critical for both safety and efficiency.

Cost is always a key factor for automotive production, and zinc often comes out ahead compared to materials like aluminum. Zinc’s lower melting point allows for faster production cycles, reducing energy costs and speeding up manufacturing. Plus, zinc tooling tends to last longer, so it’s more cost-effective over time.

For exterior auto parts, zinc’s natural corrosion resistance makes it ideal. Zinc alloys protect against rust and weather damage without needing extra coatings, which keeps maintenance low and lifespan high.

Lastly, zinc is highly sustainable and recyclable, perfect for car makers focusing on eco-friendly practices. Zinc alloys can be melted down and reused with minimal loss of quality, supporting greener automotive manufacturing.

At HYCNC, we bring deep expertise in zinc die casting services tailored for automotive needs. Our advanced CNC machining and quality control processes ensure your zinc parts meet the highest standards of precision and performance. We combine technical know-how with cost efficiency to help U.S. auto manufacturers stay competitive and sustainable.

For a deeper dive into the zinc die casting process and how it compares to other metals, check out our detailed post on What is Zinc Die Casting.

Key Applications of Zinc Die Casting in Automotive Manufacturing

Zinc die casting plays a crucial role in making reliable automotive parts that need strength, precision, and durability. Here’s where zinc die casting shines in the auto industry:

-

Safety Components

Zinc alloys are perfect for safety-critical parts like seatbelt pulleys and door lock housings. These components demand high strength and tight tolerances, which zinc die casting provides consistently.

-

Engine and Transmission Parts

Camshafts, brackets, and other engine or transmission-related parts benefit from zinc’s durability and corrosion resistance. Using zinc alloys helps improve longevity while keeping manufacturing costs in check.

-

Exterior and Interior Parts

From sunroof brackets to interior trims, zinc die casting ensures parts are lightweight yet strong enough to handle daily use and exposure. Its corrosion resistance also makes it great for exterior components subject to weather conditions.

HYCNC Case Study Optimizing a Zinc Die-Cast Sunroof Bracket

At HYCNC, we recently helped an automotive client improve their zinc die-cast sunroof bracket. By fine-tuning the casting and CNC machining process, we enhanced the part’s strength and precision while reducing waste and lead times. This collaboration highlights how expert zinc die casting services can boost both quality and efficiency in automotive manufacturing.

These applications show why zinc die casting continues to be a top choice for making cost-effective, high-performance automotive parts.

Zinc vs Aluminum Die Casting A Comparison for Automotive Use

When it comes to choosing between zinc and aluminum die casting for automotive parts, there are some clear differences to keep in mind.

Melting point and production speed

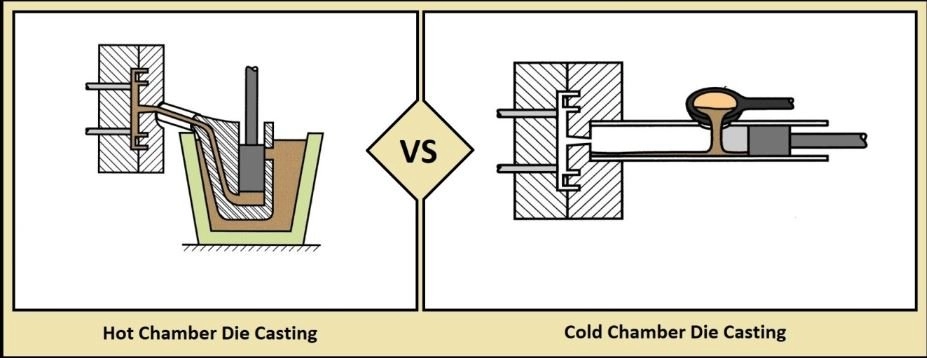

Zinc has a lower melting point (around 787°F) compared to aluminum (about 1,221°F). This means zinc melts faster, allowing for quicker production cycles. In hot chamber die casting, zinc’s lower melting point speeds up the casting process and reduces energy use, giving it an edge for high-volume automotive manufacturing.

Cost variation and tooling considerations

Zinc alloys usually cost less than aluminum, both in raw materials and tooling. Zinc tools can handle higher production volumes before needing replacement. However, zinc die casting molds can have higher initial costs, especially for large or complex parts. But over time, the durability and speed often make zinc more cost-effective.

Zinc advantages in thin-wall casting and hot chamber processes

Zinc excels in thin-wall casting. Its fluidity allows it to fill intricate, tight-tolerance molds better than aluminum, making it ideal for precision automotive parts like brackets and housings. Also, zinc works well with hot chamber die casting, a faster and more efficient method than the cold chamber process typically used for aluminum.

Guidance on choosing zinc over aluminum

- Opt for zinc when precision, thin walls, and high volume production are priorities.

- Choose zinc if you want parts with better corrosion resistance for exterior automotive components.

- Aluminum might be better where lightweight and high-temperature resistance are critical.

- For cost-conscious projects needing fast turnaround, zinc’s production speed and tooling life can lead to savings.

For more details on zinc vs aluminum die casting, check out our in-depth comparison on Zinc Die Casting vs Aluminum Die Casting.

How HYCNC Enhances Zinc Die Casting for Automotive Clients

At HYCNC, we take zinc die casting for the automotive industry to the next level with our advanced CNC machining and die casting capabilities. Our precise CNC service ensures every zinc alloy automotive part meets tight tolerances, delivering consistent quality that automotive manufacturers rely on.

We use state-of-the-art equipment combined with rigorous quality control processes to maintain high standards throughout production. This helps us catch potential issues early, ensuring durable and reliable parts like engine brackets and safety components.

From prototyping to mass production, HYCNC offers custom solutions tailored to your project needs. Whether you’re developing a new zinc die cast sunroof bracket or requiring large-scale runs, we handle it efficiently and cost-effectively.

Plus, we’re committed to sustainability—our zinc die casting process focuses on recyclability and reducing waste, helping automotive manufacturers meet environmental goals without sacrificing performance or budget.

Learn more about our die casting services and how HYCNC can optimize your automotive zinc casting projects.

Challenges and Considerations in Zinc Die Casting

Zinc die casting does come with a few challenges worth noting. First, the initial mold costs are higher than some other processes. Creating precise molds for zinc alloys requires careful design and investment upfront. Also, size limitations exist because zinc die casting is best suited for smaller to medium-sized parts, so very large automotive components might not be ideal for this method.

Another important factor is the need for skilled operation. Controlling the temperature and pressure during the hot chamber die casting process is critical to avoid defects and ensure consistent quality. This means experienced technicians and precise equipment are a must.

At HYCNC, we tackle these challenges head-on. Our team is trained to handle the complex demands of zinc die casting with advanced controls and monitoring systems. We invest in top-tier mold manufacturing to reduce long-term costs and maximize mold life. Plus, our expertise helps clients get the best results, balancing quality and efficiency even with size constraints. This way, we keep your automotive parts reliable and cost-effective without compromises.

The Future of Zinc Die Casting in the Automotive Industry

Zinc die casting is set to evolve quickly as new technologies and market needs come into play. One big trend is vacuum die casting, which improves part quality by reducing air bubbles and defects. This means stronger, more reliable zinc alloy automotive parts, perfect for safety and precision components carmakers need today. On top of that, Industry 4.0 integration is changing the game—smart machines and data-driven processes help HYCNC and others streamline production, improve quality control, and reduce waste.

The automotive world is pushing hard for lighter, more fuel-efficient vehicles to meet stricter regulations and driver preferences here in the U.S. Zinc die casting fits right in because zinc parts offer excellent strength without added weight. Plus, zinc alloys are highly recyclable, which aligns with sustainability goals many manufacturers now prioritize.

At HYCNC, we’re proud to be at the forefront, combining advanced CNC machining with innovative die casting techniques. By investing in cutting-edge equipment and tapping into these trends, we help automotive clients design cost-effective, durable zinc components that meet tomorrow’s challenges—whether that’s boosting performance or cutting environmental impact.