What is Sheet Metal Hemming

Sheet metal hemming is a metal forming technique used to fold and flatten the edge of a sheet metal part. It helps reinforce the edge by creating a smooth, double thickness fold. Though often mentioned alongside seaming, hemming and seaming serve different purposes. Hemming focuses on bending the metal edge flush without joining two pieces permanently, while seaming typically involves locking two edges together to form a tight seam.

This precise technique plays a critical role in industries where durability and finish quality are essential. Automotive, aerospace, electronics, and consumer goods manufacturing all rely on meticulous sheet metal hemming to improve the structural integrity and appearance of their products. Precision is key because even slight variations can affect fit, strength, and function, making expert CNC machining services invaluable.

Types of Sheet Metal Hems

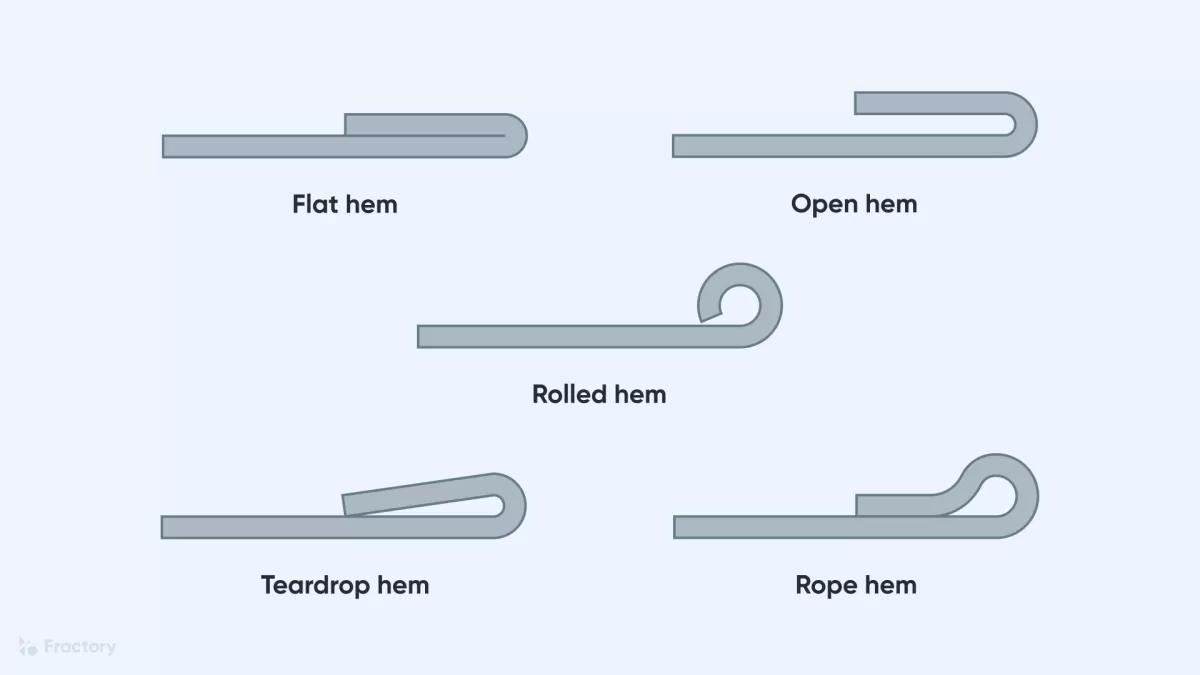

Sheet metal hemming comes in several common types, each serving different purposes depending on the part design and application. Here are the main types you’ll encounter:

-

Closed Hem

This type folds the metal edge over completely, creating a smooth, doubled edge. Closed hems add strength and eliminate sharp edges, making them great for safety and durability.

-

Open Hem

Unlike closed hems, open hems fold the edge without fully closing it, leaving a small gap. Open hems are easier to form and can be useful when tight bends might cause cracking.

-

Teardrop Hem

This hem forms a rounded shape resembling a teardrop, which helps reduce stress and distortion in the metal. Teardrop hems are often used when longer flange lengths or gentle curves are needed.

-

Rolled Hem

Rolled hems curl the edge of the sheet tightly, providing a neat finish and reinforcing the metal edge. This type is typically used in thin sheets or for decorative purposes.

-

Rope Hem

Rope hems create a thicker, rope-like edge by doubling the folding process several times. They offer high edge strength and are common in applications where added durability is key.

Material and Thickness Considerations

Choosing the right type of hem depends heavily on the material and thickness of your sheet metal. Thicker metals require more force to bend and may be prone to cracking if bent improperly. Softer materials like aluminum or mild steel handle tighter hems better than hard, brittle metals. When planning your hemming process, consider:

- Material ductility: Softer metals are easier to hem without cracking.

- Thickness: Thicker sheets may need open or rolled hems to reduce stress.

- End use: Safety, strength, and appearance goals dictate the best hem type.

Getting the hem type right upfront helps avoid deformation and maintains the structural integrity of your project. For details on other metal forming techniques that combine well with hemming, check out our metal bending services.

Sheet Metal Hemming Processes

Sheet metal hemming mainly involves two popular methods: die hemming and roller hemming. Each has its own steps, tools, and best-use scenarios.

Die Hemming

Die hemming uses a set of matched punches and dies to fold the metal edge over itself. The process typically includes:

- Positioning the sheet metal blank on the die

- Lowering the punch to bend the flange towards the main sheet

- Folding the edge fully to create a smooth, closed hem

This method is widely used in automotive and aerospace industries because it offers high precision and strong, clean hems. Die hemming works best for medium to thick materials and parts requiring sharp, closed edges.

Roller Hemming

Roller hemming gradually bends the metal edge with a rolling tool, rather than pressing it all at once. It’s common for large panels or delicate materials where minimizing deformation is key. The steps include:

- Clamping the sheet metal firmly

- Using a powered roller tool to slowly fold the edge

- Applying multiple passes for a smooth, uniform hem

Roller hemming is favored in HVAC and appliance manufacturing due to its gentle metal handling and ability to process complex shapes.

Tools and Equipment

Sheet metal hemming relies on precise, durable equipment. At HYCNC, we use advanced CNC-machined dies and automated roller hemming tools that maintain exact tolerances and repeatability. Our CNC technology enhances quality control and speeds up production, delivering consistent hems for custom CNC parts and sheet metal fabrication projects.

By combining expert die and roller hemming capabilities with state-of-the-art CNC machinery, HYCNC offers reliable hemming solutions tailored to your material and design requirements. Whether you need metal edge reinforcement or complex automotive sheet metal parts, our processes ensure strength and precision.

For more on sheet metal processes, check out our sheet metal manufacturing insights.

Benefits of Sheet Metal Hemming

Sheet metal hemming offers several clear advantages that make it a popular choice in various industries. One major benefit is structural integrity. Hemming bends the metal edges back onto themselves, which strengthens the part and reinforces metal edges, reducing the risk of cracks or sharp edges that could cause injury.

Safety is another key benefit. Hemmed edges remove sharp metal points, making parts safer to handle during manufacturing and assembly. This also improves the final product’s usability and reduces injury risks for end users.

From an aesthetic standpoint, hemming creates clean, smooth edges that enhance the product’s overall look. This is especially important in consumer goods and automotive sheet metal where visual appeal matters.

Another advantage is reduced finishing work. Since the edges are folded in and secured, less grinding or deburring is needed, saving time and cutting production costs.

Hemming also facilitates assembly. Hemmed parts fit together more precisely, improving the accuracy and speed of assembly lines.

At HYCNC, we ensure top-notch quality control throughout our CNC machining services, including precision hemming. Our advanced processes maintain consistent bends and dimensions, which is key for reliable, high-quality sheet metal fabrication.

If you’re looking for expert sheet metal hemming that boosts both form and function, HYCNC’s CNC technology guarantees exceptional results every time. For more insights on related metal forming techniques, check out our service on sheet metal fabrication.

Challenges and Considerations in Sheet Metal Hemming

Sheet metal hemming isn’t without challenges. It can be time-consuming, especially with complex shapes or thicker materials. The process also carries a risk of deformation if not done right, which can affect the part’s fit and function.

You’ll need skilled operators familiar with precision hemming and metal forming techniques to maintain quality. Material selection is critical too—some metals are easier to hem than others, and thickness plays a big role in how the metal behaves under bending.

To set yourself up for success, keep these tips in mind:

- Choose the right metal and thickness for your application

- Use experienced operators who understand hemming nuances

- Focus on precise machine setup to avoid deformation

- Plan for extra time on complex bends

At HYCNC, we tackle these challenges head-on. Our advanced CNC machining services and quality control ensure consistent results with minimal deformation. Plus, our expert team helps guide material choices and process settings for every project. This means less guesswork and smoother production for your sheet metal fabrication needs.

Applications of Sheet Metal Hemming

Sheet metal hemming plays a big role across many industries where precision and strength are key. Here’s how it’s used:

- Automotive: Hemming strengthens body panels and doors, improving safety and appearance. It’s crucial for tight edges and preventing sharp finishes in cars and trucks.

- Aerospace: Lightweight but strong hems help meet strict standards for aircraft parts, ensuring durability and aerodynamic efficiency.

- Electronics: Hemming secures metal enclosures, protecting sensitive components while giving a clean look.

- HVAC: Air ducts and metal housings get reinforced edges with hemming, improving airflow and reducing leaks.

- Consumer Goods: From appliances to outdoor equipment, hemming adds durability and polish to metal parts.

Case Study

A U.S.-based automotive parts supplier turned to precision hemming on their CNC machines to improve door panel assembly. By switching to die hemming, they reduced edge defects and cut assembly time by 15%, boosting overall production quality and customer satisfaction.

Sheet metal hemming is a trusted technique that strengthens and refines metal parts across many essential markets.

Why Choose HYCNC for Sheet Metal Hemming

When it comes to sheet metal hemming, HYCNC stands out for several reasons. We use advanced CNC machinery that ensures precision hemming every time. Our equipment allows us to handle a variety of metal forming techniques, from die hemming process to roller hemming technique, delivering top-notch quality.

We bring expertise gained from years of working with automotive sheet metal, electronics, and more. Our team knows the importance of exact metal edge reinforcement and consistently meets industry standards. Plus, HYCNC is ISO certified, so you can trust in our commitment to quality and reliability.

We offer custom solutions tailored to your unique sheet metal fabrication needs, ensuring your parts meet exact specs. Need a quick turnaround? We provide fast quotes and smooth communication to keep your projects on track.

Choose HYCNC for precision, reliability, and service that supports your success in the US market. Contact us today to discuss your sheet metal hemming needs.

Best Practices for Designing Hemmed Parts

When designing parts that need sheet metal hemming, getting it right from the start saves time and cuts costs. Here are some key tips:

- Choose the right hem type for the job. Open hems work well for thicker metals or when you need less stress on the material. Closed hems offer a smooth edge but can be tougher to form on thicker sheets.

- Keep flange lengths consistent and adequate. Too short a flange can cause weak hems or cracks. A good rule is to keep the flange at least twice the material thickness.

- Avoid closed hems on very thick or hard materials. They’re harder to form and have higher chances of metal deformation.

- Use CNC precision technology. CNC machining services ensure your hemming steps are exact, reducing errors and waste.

- Collaborate with experienced sheet metal fabrication experts. Getting advice early saves headaches later. Experts can help design hems that fit your manufacturing process and material choice.

Following these practices ensures your hemmed parts have strong edges, look great, and perform well in their final use.