Are you wondering about the types of tack welds and how they can elevate your manufacturing projects? Choosing the right tack welding techniques is critical for ensuring precision and efficiency, especially in CNC machining. As experts in precision manufacturing, we at HYCNC understand the challenges of achieving flawless welds in complex assemblies. In this guide, you’ll discover the different types of tack welds, their practical applications, and expert tips to optimize your welding process. Whether you’re a welder, engineer, or CNC enthusiast, this post will equip you with actionable insights to master tack welding. Let’s get started!

What Is Tack Welding

Tack welding is a temporary welding process used to hold metal parts together before final welding. These small welds act like clamps, securing components in place to ensure proper alignment, stability, and precision throughout manufacturing.

In industries like CNC machining and sheet metal fabrication, tack welding plays a crucial role by keeping parts steady during assembly and machining. It helps maintain exact positioning, which is essential when working with tight tolerances.

The benefits of tack welding include cost-efficiency since it reduces the need for expensive fixtures, minimizes distortion by limiting heat input, and offers flexibility for adjustments before the final weld is applied. This makes tack welding an important step in producing high-quality metal assemblies with less waste and downtime.

Types of Tack Welds

Standard Tack Welds

These are small welds placed within the joint that get fully melted and blended into the final weld. They’re common in general assembly, sheet metal fabrication, and CNC machining where keeping parts aligned is critical. The main benefits are maintaining precise alignment while adding minimal heat to avoid warping. For best results, keep tack sizes consistent, space them evenly, and ensure they’re compatible with the final welding process.

Bridge Tack Welds

Bridge tacks are used to connect parts that have small gaps or slight misalignment. They’re popular in pipe welding and CNC assemblies where tight tolerances matter. These welds help control distortion by allowing cooling between tacks, reducing stress on the material. Best practices include alternating tack locations and using appropriate welding methods like MIG or TIG to manage heat and strength.

Hot Tack Welds

Hot tacks involve depositing filler metal and hammering it to close gaps quickly. They’re handy for fast fixes but are less common in precision CNC work due to a higher chance of defects and failing quality checks. It’s best to avoid hot tacks in projects where accuracy matters and reserve them for non-critical or temporary setups.

Other Variations

Some tack welds are designed specifically for thin materials, often seen in automotive and lightweight CNC sheet metal work. These localized welds minimize distortion and speed up the welding process. To get the best outcome, adjust heat settings carefully and keep surfaces clean before tacking.

Applications of Tack Welds in CNC Machining

Tack welds play a crucial role when working with CNC machining. They help secure parts during milling, turning, and cutting by holding everything in place without moving. This is especially important for parts with complex shapes or tight tolerances where even slight shifts can cause problems.

In fixturing, tack welds keep components steady while multiple operations happen, ensuring consistent accuracy across all steps. For custom fabrication projects, like those done by HYCNC, tack welding supports quick setup and adjustments without permanent joins until final welding.

Whether you’re handling low-volume jobs or big production runs, tack welds offer flexibility. For smaller batches, they speed up the process by reducing the need for expensive fixtures. In high-volume production, they maintain repeatable precision and reduce distortion, keeping quality consistent throughout.

Pros and Cons of Tack Welding

Tack welding offers several clear advantages, especially in manufacturing and CNC machining:

- No Costly Fixtures: Tack welds hold parts securely without needing expensive clamps or fixtures.

- Improved Precision: They keep components aligned, which helps maintain tight tolerances.

- Reduced Distortion: Since tack welds use less heat than continuous welds, they minimize warping or distortion.

- Design Flexibility: Tack welding makes it easy to adjust and reposition parts before final welding.

However, there are some downsides to keep in mind:

- Skilled Labor Needed: Quality tack welding requires experience to avoid mistakes.

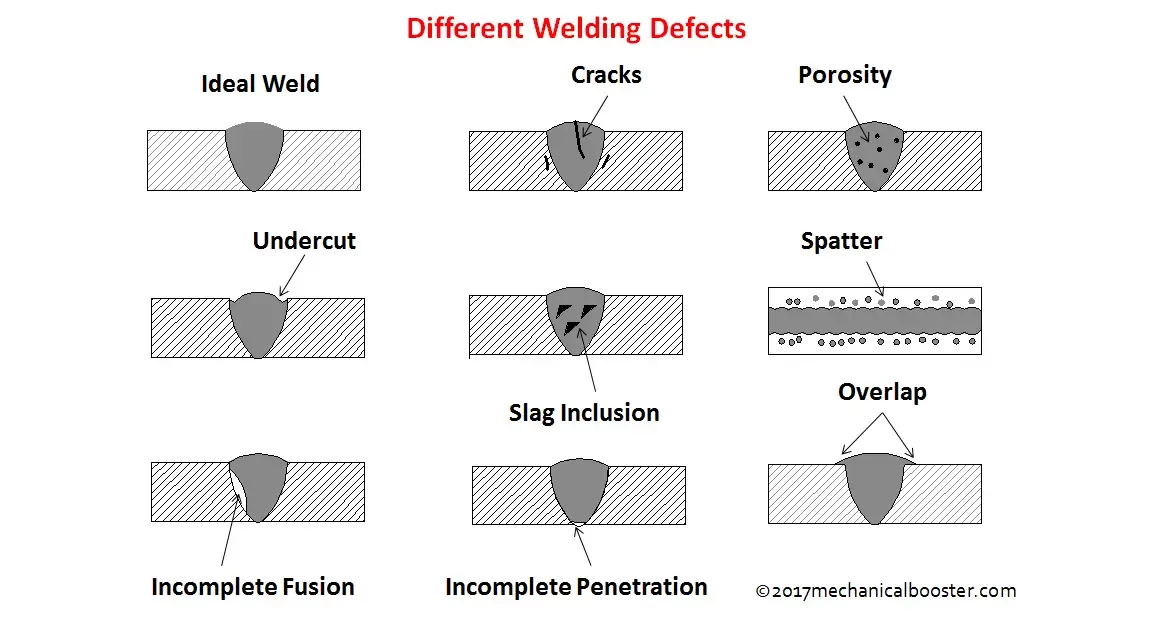

- Possible Defects: Poorly done tack welds can lead to misalignment or weak joints.

- Temporary Strength: Tack welds aren’t designed to hold parts under heavy stress long-term.

- Residual Stresses: Improper tack welding can create stresses in the metal, affecting final quality.

Overall, tack welding is a valuable tool when used correctly, balancing efficiency and precision in metal fabrication.

Best Practices for High Quality Tack Welds

To get the best results with tack welding, start with proper material preparation. Make sure all surfaces are clean and free of rust, oil, or dirt. This helps the weld stick well and keeps the joint strong.

Next, pick the right equipment. Use the same welding method for tacks as your final weld, whether that’s MIG or TIG. Matching the equipment ensures a consistent weld bead and avoids problems during full welding.

When it comes to technique, pay close attention to:

- Spacing: Place tacks evenly to hold parts securely without overheating.

- Heat control: Use just enough heat to fuse without warping or distorting metal.

- Weld sequence: Tack parts in a balanced pattern to reduce stress and keep joints aligned.

After tacking, always perform quality checks. Inspect the welds to ensure proper alignment and enough strength to hold parts firmly during machining or handling.

For CNC projects, work with a provider like HYCNC that focuses on precision. Their approach to tack welding combines tight tolerances with expert technique, helping you avoid delays and get parts right the first time.

Tack Welding vs Alternatives

Tack welding serves as a quick, temporary way to hold parts in place before final welding, especially in CNC machining projects. Unlike spot welding, which creates permanent bonds by fusing metals at specific points, tack welds are meant to be temporary and easily removed or finished with a full weld later. This makes tack welding ideal for adjustments and alignment during fabrication.

There are alternatives to tack welding for holding parts together:

- Clamping: Mechanical clamps secure parts without any welding. Great for quick setups but can be bulky and limit access.

- Magnetic fixtures: Useful for holding ferrous metals, especially flat or simple shapes. They’re fast but less precise for complex geometries.

- Temporary fasteners: Bolts, screws, or pins can hold parts but add extra steps and might get in the way during machining.

For CNC projects, tack welding strikes a good balance by keeping parts aligned while allowing flexibility to reposition if needed. It’s cost-efficient, minimizes distortion, and works well with precision welding methods used in automated or manual CNC fabrication. Choosing tack welding often results in better alignment and cleaner final joints than relying solely on clamps or magnetic fixtures.

For more on welding techniques that improve precision and quality, check out our guide on prevent cracking in tack welds.

FAQs About Tack Welds

What’s the difference between tack welding and spot welding?

Tack welding uses small, temporary welds to hold parts in place before the final weld. Spot welding joins sheets by applying pressure and electricity at points, creating permanent spots without filler metal. Tack welds are great for alignment and setup, while spot welds are more about quick, permanent joins.

How do tack welds improve CNC machining outcomes?

Tack welds secure parts firmly, ensuring precise positioning during milling, turning, or cutting. This avoids movement that could throw off dimensions, helping maintain tight tolerances and reducing rework costs in CNC projects.

What materials work best for tack welding?

Most metals common in CNC and sheet metal fabrication—like mild steel, stainless steel, and aluminum—tack well. Clean surfaces and proper technique are key. Some thin materials need careful heat control to avoid distortion or burn-through.

Are tack welds suitable for high volume production?

Definitely. Tack welding speeds up assembly by stabilizing parts quickly. It’s cost-effective and flexible, especially when combined with CNC machining. Skilled operators and consistent quality checks make it reliable for both small runs and larger batches.

How does HYCNC ensure quality in tack welding?

HYCNC integrates tack welding into its precision CNC services by:

- Preparing clean, precise fixturing before tack welding

- Using skilled welders paired with the right equipment (MIG or TIG) for each job

- Applying strict quality inspections on alignment and weld integrity

- Adjusting tack weld size and placement for minimal distortion based on part design

This approach keeps every component steady for perfect CNC machining and high-quality finished products.