Are you battling spot welding defects that compromise your weld quality? Imperfections like weld spatter, weak welds, or electrode degradation can derail production and drive up costs. As a manufacturing professional, I understand the frustration of inconsistent welds and the need for reliable solutions to common defects in spot welding. Drawing from real-world industry experience, this guide dives deep into practical fixes and preventive strategies to ensure flawless welds every time. From optimizing parameters to leveraging CNC welding automation, you’ll discover expert tips to elevate your welding process. Let’s get started!

Understanding Spot Welding and Its Challenges

Spot welding is a popular resistance welding method mainly used to join thin sheets of metal, especially in industries like automotive and sheet metal fabrication. It works by applying pressure and an electric current through metal pieces to create a weld at small contact points or “spots.” It’s fast, efficient, and perfect for high-volume production. But despite its simplicity, spot welding can face several challenges that impact weld quality and overall reliability.

Common issues like weak welds, cracks, or weld spatter often sneak in when welding parameters aren’t optimized or maintenance is overlooked. Material variations, dirty surfaces, and electrode wear also cause defects that reduce strength and increase rework costs. Even experienced operators can face these challenges, from inconsistent weld sizes to electrode degradation.

Understanding these challenges is the first step to achieving strong, consistent welds. It involves knowing what causes spot welding imperfections and how factors such as current, pressure, and timing interact. With this knowledge, you can avoid common resistance welding defects and ensure every weld meets quality standards, saving time and expense in production.

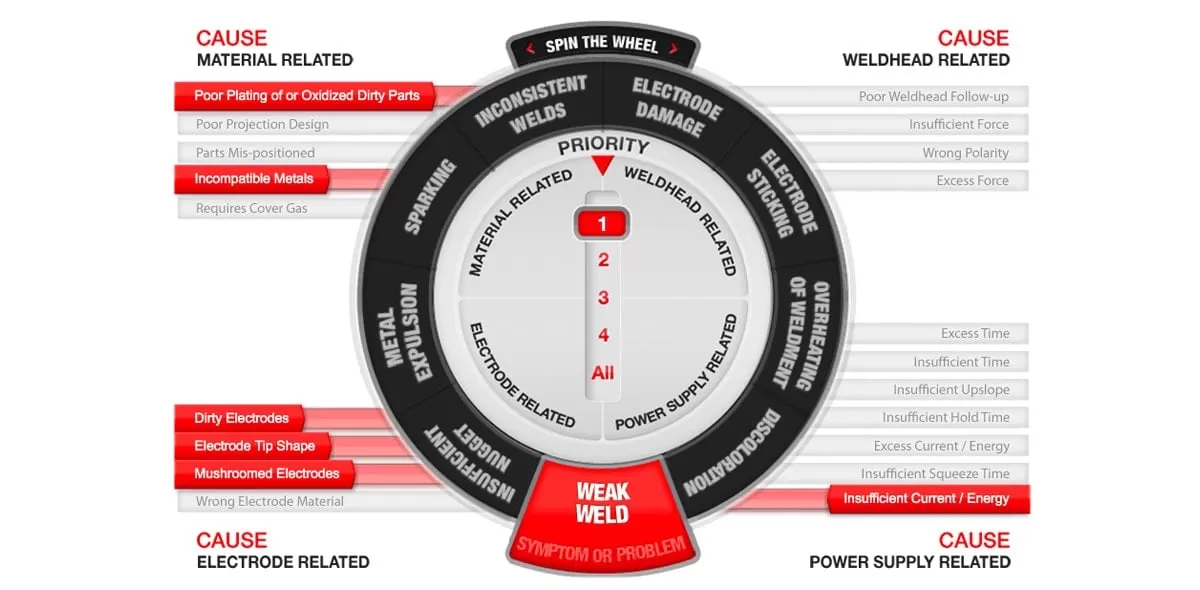

Common Spot Welding Defects and Their Causes

When it comes to spot welding, several common defects can affect the strength and quality of the welds. Knowing these issues and their causes helps us address them quickly.

Weld Spatter Expulsion

This happens when molten metal splashes out during welding. It’s often caused by too high welding current or improper electrode pressure, leading to messy weld spots and potential weak points.

Undersized or Weak Welds

If the weld nugget is too small, the joint won’t hold up under stress. This usually results from low current, short welding time, or dirty metal surfaces that prevent proper fusion.

Cold False Welds

These are welds that look okay on the surface but don’t actually fuse the metals well. Causes include incorrect welding parameters or contamination on the metal, leading to poor electrical contact and no real bonding.

Excessive Indentation

This defect shows up as deep marks on the metal around the weld. It’s often caused by too much electrode force or too long welding time, which can weaken the material near the weld.

Asymmetrical Weld Marks

When weld spots aren’t evenly shaped or centered, it could indicate misaligned electrodes or uneven pressure. This can cause inconsistent weld strength and appearance issues.

Electrode Degradation

Electrodes wear down over time due to heat and pressure. This degrades weld quality by causing inconsistent current flow and poor contact, leading to weak or uneven welds.

Cracks and Holes

These show up when the weld cools too quickly or the materials don’t match well. Cracks reduce the durability of the weld, while holes can form from trapped gases or contaminants, weakening the joint.

Understanding these spot welding imperfections and resistance welding defects is the first step to improving your weld quality. Addressing their causes ensures stronger, cleaner welds every time.

Practical Solutions to Prevent and Fix Spot Welding Defects

To tackle common spot welding imperfections, addressing the root causes is key. Here are some proven solutions that improve weld quality and prevent resistance welding defects:

Optimizing Welding Parameters

- Adjust current, pressure, and weld time based on material thickness and type.

- Avoid under or over-welding to prevent weak or cold false welds.

- Use trial runs to fine-tune settings for consistency.

Ensuring Proper Electrode Maintenance

- Regularly clean and dress electrodes to remove build-up and maintain shape.

- Replace worn-out electrodes promptly to stop poor heat transfer and uneven welds.

- Use electrode maintenance tips like scheduled checks to extend electrode life.

Improving Material Preparation

- Clean metal surfaces to remove oils, rust, or coatings that cause poor welds.

- Align workpieces carefully to avoid asymmetrical weld marks and cracks.

- Use guidelines from welding tips for laser and waterjet cut parts for better prep.

Leveraging Automation and Precision Tools

- Utilize CNC welding automation to maintain exact parameters for repeatable quality.

- Employ sensors and monitoring systems for real-time feedback and quick adjustments.

- Automation reduces human error, boosting weld quality improvement.

Conducting Regular Inspections

- Perform routine weld inspection techniques like visual checks or non-destructive testing.

- Catch defects early, such as cracks or holes, before they affect production.

- Use inspection results to refine welding processes continuously.

Implementing these practical solutions helps US manufacturers reduce spot welding imperfections and maintain high standards in sheet metal fabrication. For more insights on welding defects and fixes, check out our detailed welding defects guide.

Advanced Techniques for High Quality Spot Welding

To reach top-quality spot welding results, it’s vital to move beyond basic fixes and use advanced techniques. Here’s how you can boost your weld quality through smarter methods:

Welding Simulations

Using welding simulations helps predict and prevent spot welding imperfections before running actual tests. Simulations allow you to identify weak points, optimize welding parameters like current and time, and reduce trial-and-error efforts. This saves both time and materials, making your process more efficient and consistent.

Parameter Adjustments for Coated Materials

Coated metals, like galvanized steel, need special care. Coatings can affect heat transfer and cause resistance welding defects such as weak welds or spatter. Adjusting welding parameters—like increasing weld current or time—helps ensure good penetration without damaging coatings. Fine-tuning these settings helps maintain weld integrity while preserving metal coatings.

Training and Skill Development

Even with the best machines, skilled operators make the difference. Consistent training keeps your team updated on the latest welding techniques, troubleshooting tips, and safety standards. Emphasizing hands-on practice plus knowledge of weld inspection techniques boosts confidence and reduces human errors that lead to defects.

By combining welding simulations, precise parameter adjustments, and ongoing training, you create a strong foundation for high-quality, consistent spot welds that meet industry standards and customer expectations in the U.S. manufacturing sector.

For more on avoiding common welding issues, check out our detailed post on welding defects.

How HYCNC Can Help Solve Spot Welding Challenges

At HYCNC, we understand how frustrating spot welding imperfections can be, especially when tight deadlines and quality standards are on the line. Our CNC machining and sheet metal fabrication services are designed specifically to tackle common resistance welding defects and improve overall weld quality for manufacturers across the U.S.

Here’s how we help solve spot welding challenges:

-

Custom CNC Welding Automation

We provide precision CNC automation that controls welding parameters accurately. This helps reduce weak welds, cold false welds, and inconsistent weld marks by maintaining consistent heat and pressure during every spot weld.

-

Electrode Maintenance and Replacement

We offer expert electrode maintenance tips and quick electrode replacement, preventing common issues like electrode degradation and excessive indentation, which can affect weld strength and appearance.

-

Material Preparation Services

Proper metal preparation is key to avoiding weld spatter and cracks. Our team ensures surfaces are prepped correctly, so you get high-quality welds without unnecessary rework.

-

Regular Weld Inspection and Quality Assurance

Using advanced weld inspection techniques, we catch spot welding defects early. This proactive approach helps you avoid costly scrap and keeps production flowing smoothly.

-

Tailored Solutions for Coated and Complex Materials

HYCNC’s experience with various materials and coatings means we can adjust welding parameters to suit your specific needs, minimizing defects even with challenging metals.

By combining skilled CNC service with spot welding know-how, HYCNC becomes your partner in reducing defects, boosting production efficiency, and delivering spot welds that meet the high standards U.S. manufacturers expect. Whether you’re dealing with common spot welding issues or looking to optimize your welding line, our solutions get the job done right.

Preventing Defects Through Quality Control

Quality control is a must if you want to avoid spot welding imperfections and keep your production smooth. Here’s how you can stay on top of things:

-

Regular Weld Inspections: Use visual checks and nondestructive testing to catch resistance welding defects early. Spot checking helps spot weak welds, cracks, or holes before they cause bigger problems.

-

Consistent Parameter Monitoring: Keep an eye on welding parameters like current, time, and pressure. Small changes can lead to poor weld quality, so regularly verify settings to maintain optimal conditions.

-

Electrode Condition Checks: Inspect electrodes for wear or damage often. Proper electrode maintenance prevents defects like weld spatter and excessive indentation, which hit weld strength and appearance.

-

Material Verification: Make sure your metal surfaces are clean and prepared correctly before welding. Dirt, rust, or coatings can lead to cold false welds or uneven spots.

-

Document and Analyze: Track defect trends and frequent issues. This data helps you adjust processes, improve training, or fine-tune CNC welding automation for better repeatability.

By building quality control into your spot welding workflow, you not only reduce resistance welding defects but also improve overall weld quality. This means less downtime, higher throughput, and components that meet your standards every time.