Are you struggling to design nested shapes for CNC machining without losing parts during the cut? Creating bridges for nested shapes can be a game-changer for your projects.

As a CNC expert, I’ve seen how the right bridge design ensures precision and saves time, whether you’re crafting intricate ornaments or industrial components. With years of experience at HYCNC, I’m sharing practical, no-nonsense tips to help you master this process.

In this guide, you’ll discover how to create bridges that keep your nested shapes secure, avoid costly mistakes, and streamline your CNC machining workflow.

Let’s get started!

What Are Nested Shapes and Why They Need Bridges

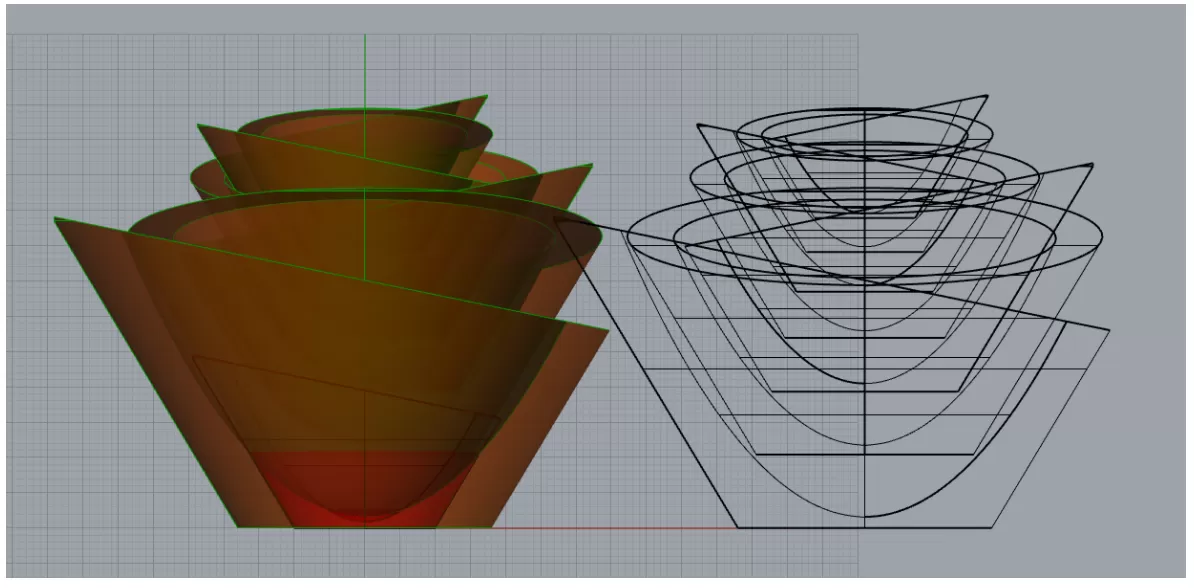

Nested shapes are multiple designs placed closely together within the same material sheet to maximize space and reduce waste during CNC machining or laser cutting. Think of cutting several small wooden ornaments out of one big plank, where the shapes fit snugly around each other like puzzle pieces.

The challenge with nested shapes is that when the machine finishes cutting, the individual pieces can fall out or detach prematurely. This detachment can cause damage or loss of small or intricate shapes, especially if they’re surrounded by cutouts.

That’s where bridges come in. Bridges are small, intentional connectors left between the nested shapes and the surrounding material. They hold the pieces in place during cutting, preventing them from shifting or getting lost until you’re ready to remove them safely. For example, when laser cutting a set of nested gears, bridges keep the teeth from breaking or dropping out during the process, ensuring every gear stays intact and easy to handle.

Without bridges, nested shapes can easily detach and cause scrap, rework, or project delays—which makes bridges essential in CNC nested shape design.

Understanding Bridges in CNC Design

Bridges are small connectors left between nested shapes during CNC cutting to keep the inner pieces attached to the main material. Without these bridges, inner parts can fall out or shift, causing loss or damage. Think of them as tiny tabs that hold everything in place until you’re ready to separate each shape.

When designing bridges, material plays a big role in deciding their size and strength. For example, thicker wood or metal needs wider bridges for stability, while thinner sheets or delicate materials require more precise, minimal bridges to avoid weakening the overall design.

It’s important to balance how bridges look with how well they function. Too many or bulky bridges can make your final piece look messy, but too few or thin bridges risk breaking during cutting or handling. Good bridge design keeps parts secure without compromising the clean lines or quality you expect from CNC machining.

Step-by-Step Guide to Creating Bridges for Nested Shapes

Creating bridges for nested shapes is crucial to keep your pieces intact during CNC machining. Here’s how you do it right:

Step 1 Design Your Nested Shapes

Start by laying out your nested shapes in vector or CAD software like Adobe Illustrator, Inkscape, or Fusion 360. This helps you maximize material use and plan your cuts efficiently.

Step 2 Plan Strategic Bridge Placement

Decide where to add bridges based on the material you’re working with and the cutting method. Place bridges where they won’t weaken the design but will hold inner parts in place.

Step 3 Add Bridges Using Software Tools

Use tools like the Pathfinder panel in Adobe Illustrator or similar features in your software to create small connectors between nested shapes. Bridges should be wide enough to maintain strength but small enough to be easily removed later.

Step 4 Verify Design Outlines and Size Requirements

Check your design against your material thickness and machine tolerances. Make sure bridges meet the minimum size to prevent breakage during cutting but won’t leave large tabs behind.

Step 5 Prepare and Export CNC-Compatible Files

Once your design is ready and verified, export it in formats suitable for CNC machining—usually SVG, DXF, or DXF depending on your machine. Double-check file compatibility to avoid delays.

Following these steps ensures your nested shape designs stay intact and clean during machining, reducing material loss and saving you time.

Common Mistakes to Avoid When Designing Bridges

When creating bridges for nested shapes, it’s easy to trip up on a few key points. Here are the common mistakes you want to steer clear of:

-

Using too many bridges: While bridges are important to keep inner shapes intact, adding too many can make your final piece look messy and less professional. Find a good balance between stability and clean design.

-

Making bridges too thin: Thin bridges might look neat, but they’re prone to snapping during cutting or handling. Always make sure your bridges have enough thickness based on the material and cutting method to avoid breakage.

-

Ignoring material-specific guidelines: Different materials react differently to CNC cutting. For example, wood needs wider bridges than acrylic or metal. Not following these guidelines can cause parts to fall out or damage during machining.

-

Overlooking machining tolerances: CNC machines have limits on how small and precise they can cut. Designing bridges without considering those tolerances may lead to weak connections or shapes not being properly separated.

Keep these points in mind to create efficient, clean bridges that maintain both the function and look of your nested shapes. If you want detailed guidance on CAD design for CNC, check out our introduction to SolidWorks and creating a 2D sketch tutorial.

How HYCNC Ensures Success with Nested Shape Designs

At HYCNC, we specialize in handling complex nested shapes with precision and care. Our team has deep expertise in creating effective bridges and optimizing designs to prevent detachment or material loss during CNC machining.

We use advanced CNC machines equipped with the latest technology to maintain tight tolerances and deliver clean cuts every time. Our quality controls ensure each nested layout meets your exact specifications, no matter the material or complexity.

HYCNC supports a wide range of materials—from wood and acrylic to metals—and accepts multiple file formats to make your design process smooth and hassle-free. Whether your project is simple or highly detailed, we’re set up to handle it.

Ready to get started? Upload your designs for instant pricing and get expert assistance from our team to make sure your nested shapes are perfectly prepared for manufacturing.

Software Tools for Creating Bridges in Nested Shapes

When it comes to creating bridges for nested shapes, the right software makes a big difference. Popular tools like Adobe Illustrator, Inkscape, AutoCAD, and Fusion 360 offer features to add bridges easily during your design stage.

- Adobe Illustrator: Use the Pathfinder tool to combine shapes and manually add bridge rectangles. It’s great for detailed vector editing.

- Inkscape: Free and open-source, Inkscape supports node editing to create bridges by adjusting paths or adding small connecting shapes.

- AutoCAD: Ideal for precision, AutoCAD lets you draft exact bridge dimensions and place them accurately around your nested shapes.

- Fusion 360: This CAD/CAM software can simulate material removal and help place bridges while considering toolpaths and machining constraints.

For best results, always check minimum bridge sizes based on your material and CNC method before finalizing.

At HYCNC, we provide detailed tutorials and resources to help you master bridge creation and nested shape design. Whether you’re using vector software or CAD programs, our guides will walk you through each step.

Check out our Introduction to SolidWorks Creating a 2D Sketch to get started with precise CAD sketching for CNC.

If you’re unsure about your design or need help preparing files with optimal bridges, our team at HYCNC is ready to assist you, ensuring your nested shapes come out perfect every time.

Tips for Optimizing Nested Shape Designs

When working with nested shapes in CNC machining, keeping your design simple is key. Reduce unnecessary details and complexity to make cutting smoother and avoid errors.

Using fillets (rounded corners) instead of sharp edges helps improve manufacturability. Fillets reduce stress points on the material and ensure cleaner cuts.

Before going full-scale, prototype your design on a smaller scale. This helps catch any issues early and saves time and material costs.

If you’re unsure about your design or want to boost efficiency, reach out to HYCNC support. Our team can provide expert advice to optimize your nested shape designs for the best results.

For a great start with design software, check out our Introduction to SolidWorks creating a 2D sketch tutorial.

FAQs

What are bridges in CNC machining

Bridges are small uncut parts that hold nested shapes together during cutting. They prevent inner pieces from falling out or shifting, keeping your design intact until you’re ready to remove the parts.

Recommended bridge thickness for nested shapes

Bridge thickness depends on your material and cutting method, but a good rule is between 0.03 to 0.1 inches (0.8 to 2.5 mm). Too thin, and bridges break; too thick, and they’re hard to separate cleanly.

Best software for designing nested shapes with bridges

Popular tools include Adobe Illustrator, Inkscape, AutoCAD, and Fusion 360. These programs let you create vector designs and add bridges easily, making them perfect for CNC nested shape design.

HYCNC’s capability with complex nested designs

HYCNC uses advanced CNC machines plus expert quality controls to handle even the most detailed nested shapes. We support multiple file formats and materials to match your project needs precisely.

Preventing loss of inner shapes during cutting

Use strategically placed bridges in your design. Plan for bridge size and location based on your material. At HYCNC, we review your files to make sure inner shapes stay secure until final separation.