Are you struggling to export a STEP file from SolidWorks for your next project? Getting your 3D model ready for CNC machining or sharing it across CAD platforms doesn’t have to be a hassle. As an engineer or designer, I know how critical it is to create clean, compatible STEP files for seamless workflows. In this guide, you’ll discover a simple, step-by-step process to export STEP files from SolidWorks, optimized for services like HYCNC’s precision CNC machining. Packed with practical tips and troubleshooting hacks, this tutorial will save you time and ensure your files are production-ready. Let’s get started!

What Is a STEP File and Why It Matters

A STEP file is a universal 3D CAD file format used to exchange detailed product data between different CAD software. Officially known as ISO 10303, STEP (Standard for the Exchange of Product Data) files store 3D model information like geometry, assemblies, and attributes in a standardized way. This makes them ideal for sharing designs across various platforms while preserving accuracy and detail.

STEP files play a crucial role in industries that rely on precise digital models for manufacturing, especially CNC machining. With CNC, accurate 3D files ensure that machines cut parts exactly as designed, minimizing errors and material waste. That’s where HYCNC comes in — they specialize in CNC machining services that accept STEP files directly. By providing your design as a STEP file, you get seamless integration with HYCNC’s processing systems, speeding up production and improving quality.

Whether you’re designing parts for prototyping, production, or sheet metal fabrication, understanding how to export a clean, reliable STEP file from SolidWorks is key to a smooth CNC machining experience.

Preparing Your SolidWorks Model for Export

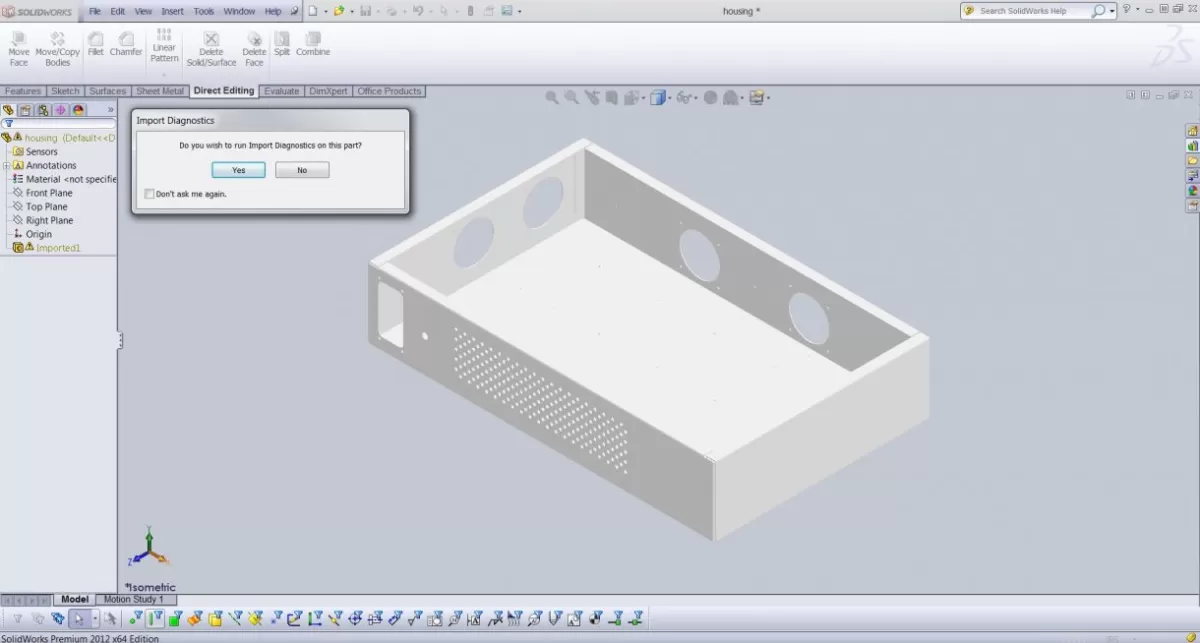

Before exporting your SolidWorks STEP file, take some time to review your model carefully. Run a quick check to catch any errors like missing faces, gaps, or overlapping parts that could cause issues when the file is used for CNC machining.

If you’re working with sheet metal, make sure your model is a single body. Most CNC services, including HYCNC, require a solid, single-body file for smooth processing. Multiple bodies can confuse the CNC software or lead to machining errors.

Also, set your material properties and appearance correctly in SolidWorks. While the STEP file doesn’t always carry over full visual details, specifying materials helps CNC providers understand what you’re working with, especially for sheet metal thickness or other critical specs. This prep step ensures your exported STEP file matches what you need for precise CNC machining.

Step by Step Guide to Export a STEP File from SolidWorks

Exporting a STEP file from SolidWorks is straightforward. Here’s how I do it:

-

Open your model in SolidWorks

Start by loading the part or assembly you want to export. Make sure the model is ready and error-free.

-

Access export options

Click on File in the top menu, then choose Save As. This opens the save dialog where you can pick your file type.

-

Select STEP format

In the Save as type dropdown, scroll and select STEP AP203/214 (.step, .stp). This ensures your file is in the right CAD file interoperability format.

-

Configure export options

Before saving, click the Options button next to the file type. Here you can choose between AP203 (basic model data) or AP214 (includes color and more detailed info).

- If exporting an assembly, choose whether to save it as a single file or multiple files based on your needs.

- Make sure to check or uncheck options like “Export all components” depending on your project.

-

Save the file

Pick your folder, enter your filename, and hit Save. SolidWorks will export your model as a STEP file.

-

Verify the export

After saving, it’s smart to open the STEP file in a neutral viewer or your CNC software (like HYCNC’s tool) to confirm everything looks right before sending it for machining.

Following these simple steps helps ensure your SolidWorks STEP file is clean and ready for use in CNC machining or sharing with other CAD programs.

Optimizing STEP Files for HYCNC CNC Machining

When preparing your STEP file for HYCNC’s CNC machining, keeping a few key points in mind helps ensure smooth processing and accurate results.

Single body requirement

HYCNC requires your model to be a single solid body whenever possible. Multiple bodies or complex assemblies can cause issues during CNC programming, so combine or simplify parts before exporting to avoid delays.

Material specifications matter

Be clear about material details like thickness and bend radius, especially for sheet metal parts. These specs directly affect machining and bending accuracy. Double-check that your model reflects the exact material properties you want HYCNC to use.

Upload tips for a smooth process

- Use the HYCNC 3D preview tool after upload to confirm your model looks correct.

- File size matters—keep your STEP files optimized but complete.

- Label your files clearly with part names and revision numbers for easier tracking.

Following these steps will help you get the most out of your HYCNC CNC machining experience. For more on managing sheet metal models in SolidWorks, see our guide on using sheet metal gauge tables in SolidWorks.

Common Issues and Troubleshooting

When exporting a STEP file from SolidWorks, a few common issues can pop up that slow down your CNC machining process or cause confusion.

Missing Bodies Problem

Sometimes, parts or bodies might not appear in the exported STEP file. This usually happens because:

- The model has multiple bodies that aren’t correctly combined or saved.

- Hidden bodies or suppressed components are still active in the assembly.

- The export settings exclude certain parts unintentionally.

To fix this, double-check your model to ensure all visible bodies are active and, if needed, combine bodies into a single solid before export.

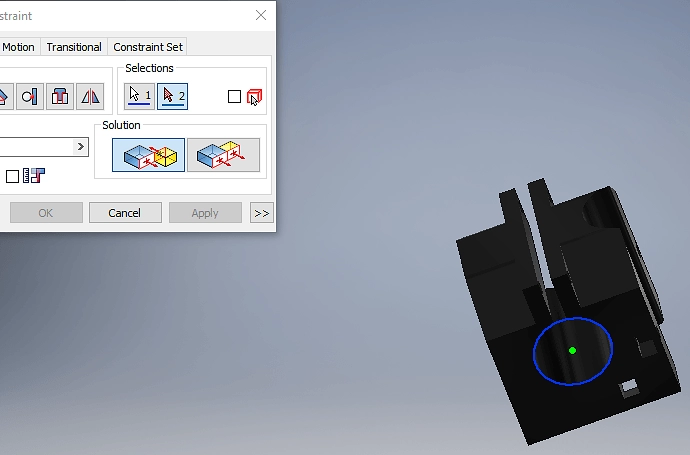

Assembly Export Challenges

Exporting assemblies to STEP can be tricky since SolidWorks offers options for exporting the entire assembly or just parts. Here’s what to watch out for:

- Make sure you select “Export assembly” if you want all components included.

- Be aware some STEP formats (like AP203 vs AP214) handle assembly data differently—AP214 supports more assembly details.

- Large assemblies may cause slow export or incomplete files if your system resources are limited.

If you encounter issues, try exporting individual parts separately or simplifying the assembly.

File Compatibility Between STEP Formats

STEP files come in different versions, mainly AP203 and AP214. Knowing which to choose is key:

- AP203 is more basic and widely compatible but doesn’t support color or layered structures well.

- AP214 supports colors, layers, and complex assemblies, good for detailed CNC machining setups.

If your CNC service or software prefers a format, stick to that to avoid compatibility problems. When in doubt, ask your CNC provider, like HYCNC, which STEP format works best for their equipment.

These simple checks and tips help avoid common export problems and keep your CNC machining running smoothly. For better assembly handling and sheet metal preparation, you can also check our post on using SolidWorks convert to sheet metal tool.

Advanced Tips for Power Users

If you’re comfortable with the basics and want to get more out of your SolidWorks to STEP conversion, here are some advanced tips:

-

Exporting Configuration Data with STEP Translator

SolidWorks lets you include configuration data when exporting STEP files. This means if your model has multiple configurations (like different sizes or versions), they can be saved in one STEP file. To do this, enable the configuration export option in the STEP translator settings. It keeps your files organized and ready for complex CNC projects.

-

Batch Exporting Using Task Scheduler

If you work with multiple files, the SolidWorks Task Scheduler can save you a lot of time. You can set it up to export several parts or assemblies as STEP files overnight or during off-hours. This is especially helpful for shops handling high volumes of CAD files.

-

Using 3D Interconnect for Better Import/Export Quality

SolidWorks’ 3D Interconnect feature improves how files from other CAD programs open and save in SolidWorks, including STEP files. Turning this on ensures better geometry accuracy and helps prevent errors during the export that can slow down CNC machining.

These tips help make your STEP exports cleaner and more efficient, especially when working with HYCNC’s CNC machining services. For a smooth process, it’s smart to familiarize yourself with these tools and options.

Why Choose HYCNC for Your CNC Machining Needs

Choosing HYCNC means you get smooth, hassle-free STEP file integration for your CNC projects. We’ve built our system to accept your SolidWorks STEP files without compatibility headaches, so you can focus on the job, not the file.

If you hit any snags uploading or exporting your STEP files, our expert support team is right here to help. We understand the ins and outs of STEP formats like AP203 and AP214 and know what CNC suppliers need to get your parts just right.

Ready to get started? Upload your STEP files to HYCNC today and experience reliable, high-quality CNC machining tailored to your specs. We keep your project on track with quick turnaround and precise results.