Why Exporting AutoCAD Files Matters for CNC Machining

If you’re working with CNC machining, you know that getting your AutoCAD files exported correctly is critical. Accurate file exports ensure your design translates perfectly into the CNC machine’s instructions. Even small errors in scale, layers, or geometry can lead to costly mistakes in the final part.

That’s why exporting AutoCAD files the right way matters—it keeps your CNC process smooth and precise. At HYCNC, we specialize in CNC processing and understand the importance of file compatibility. Our expertise helps ensure your DWG or DXF files work seamlessly with our machines, delivering accurate, high-quality results every time.

Common File Formats for CNC

When working with CNC machining, knowing which AutoCAD file format to export is crucial for smooth operations. The most common formats you’ll encounter are DWG, DXF, STEP, and PDF.

-

DWG is AutoCAD’s native file format and keeps all the detail of your drawing. It’s ideal when you’re sharing files within CAD environments or directly with CNC services like HYCNC that support DWG uploads.

-

DXF is a widely accepted format for CNC machining because it simplifies geometry and is compatible with most CNC machines and software. Use DXF when you need reliable 2D vector data for laser cutting, routing, or plasma cutting.

-

STEP files are perfect for 3D CNC workflows. If you’re working with complex 3D models or parts that require milling or 3D machining, exporting to STEP provides precise solid geometry for compatibility with advanced CNC systems.

-

PDF is generally used for sharing or documentation. It’s great when you want to send a read-only version for review or approval but not for CNC cutting, as it’s not directly used by CNC machines.

Choosing the right format depends on your workflow. For example, use DXF for most 2D CNC machining tasks, STEP for 3D part manufacturing, and DWG for full-detail CAD exchanges. PDF is best reserved for communication or paperwork.

Understanding AutoCAD Export Options

AutoCAD’s Native Export Features

AutoCAD makes exporting pretty straightforward with its built-in EXPORT command. You can save your designs in several popular formats like DWG, DXF, PDF, and SAT. Each works for different needs: DWG and DXF are great for 2D and basic 3D CNC workflows, PDF is perfect for documentation or sharing, and SAT files are used for 3D solids in CNC machining.

Limitations with 3D Bent Parts and Flat Patterns

Keep in mind, AutoCAD has some limits when dealing with complex 3D bent parts or flat patterns. It doesn’t always handle sheet metal bends or unfolding accurately. For these, you might need more specialized software or plugins to get precise CNC-ready files.

Key Considerations Before Exporting

To get the best results, double-check a few things before exporting your files:

- Make sure your drawing is at a 1:1 scale to avoid sizing errors in CNC machining.

- Remove any unnecessary annotations, dimensions, or extra layers that aren’t needed for the CNC process—this keeps files clean and easier to handle.

- Check for any non-uniformly scaled blocks or external references; these can cause errors or misalignments when exporting and CNC cutting.

Following these steps will help ensure your AutoCAD exports match CNC requirements and avoid headaches during manufacturing.

Step by Step Guide to Exporting AutoCAD Files

Exporting to DXF for CNC Machining

- Open your DWG file in AutoCAD

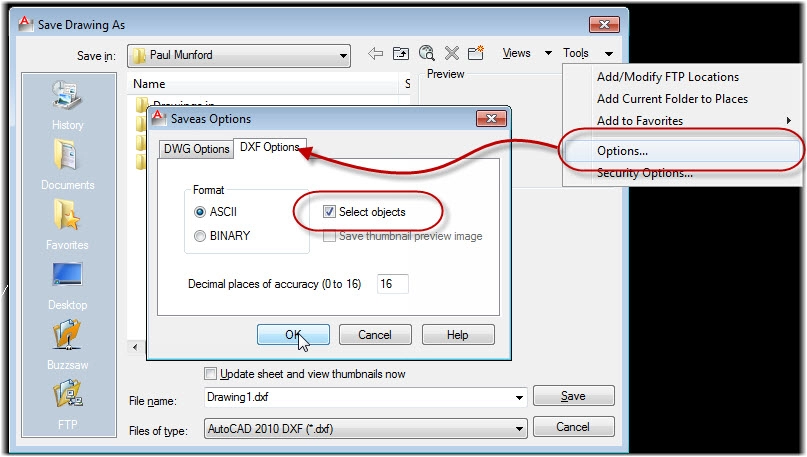

- Type the EXPORT command and choose DXF as the file format

- Enter a file name and pick where to save it

- Double-check your vector outlines and layer settings to make sure everything works smoothly with CNC machines

Exporting to PDF for Sharing or Documentation

- Pick the layout tabs you want to export

- Use the PUBLISH command and select a PDF preset

- Adjust resolution and quality settings to match your needs

Exporting to STEP or SAT for 3D CNC Workflows

- Select the 3D objects in your model

- Run the EXPORT command and save as SAT (or STEP if available)

- Keep in mind that AutoCAD has limitations with complex 3D bent parts, so check your model carefully

Using Third Party Tools for Advanced Exports

- Consider plug-ins like Spatial Manager for exporting geospatial data or formats like KML/KMZ

- These tools help handle complex CNC projects that need more than standard AutoCAD exports

This simple step-by-step approach makes exporting from AutoCAD easier and ensures you’re sending the right files for your CNC machining needs.

Preparing AutoCAD Files for HYCNC Services

Optimizing Files for CNC Machining

To get the best results with HYCNC’s CNC machining, make sure your AutoCAD files have clean vector outlines and clear bend lines. This is especially important for laser cutting or routing jobs where accuracy matters. Using HYCNC’s bending calculator can help create precise flat patterns, which saves time and reduces errors in production.

Common Mistakes to Avoid

Watch out for overlapping geometry or unclosed polylines—they can cause issues during CNC processing. Also, double-check your layer assignments and scale settings. Incorrect layers or scale problems often lead to miscuts or delays, so keep your file tidy and consistent.

Uploading Files to HYCNC

When you’re ready, upload your DWG or DXF files using HYCNC’s instant pricing tool. It’s designed for quick quotes and smooth file handling. To make the process seamless, ensure your files follow HYCNC’s recommendations on formats, layers, and scale. This way, you’ll avoid back-and-forth revisions and get your parts faster.

Troubleshooting Export Issues

Common Export Errors

When exporting from AutoCAD, you might run into a few common hiccups like:

- EXPORTLAYOUT command failure – Sometimes the command won’t work, especially with complex layouts or corrupted files.

- File size problems – Large projects with many layers and details can slow down exports or cause crashes.

- Corrupted or missing data – External references (XREFs) or blocks may not export properly, leading to incomplete files.

Solutions and Workarounds

To tackle these issues, try the following steps:

- Run AUDIT and RECOVER commands – These tools check for and fix drawing errors that might block export functions.

- Bind external references or convert to DXF – Binding external files into your main drawing or exporting as DXF can help prevent missing elements.

- Subsample large datasets – Simplify or split your drawing into smaller parts to speed up exports and reduce file size.

By addressing these common problems, you’ll save time and make sure your AutoCAD exports work smoothly with CNC machines and services like HYCNC.

Advanced Tips for AutoCAD Exports

Automating Exports with AutoLISP or Scripts

If you deal with multiple files, automating your AutoCAD exports can save a ton of time. AutoLISP is a simple scripting language built into AutoCAD that lets you create batch export routines. You can write scripts to export a bunch of drawings to DXF or PDF in one go without clicking through menus. This helps keep your CNC workflows consistent and error-free.

Exporting Attributes for BOMs or Schedules

When working on CNC projects, you often need to pull block attributes for bills of materials (BOMs) or schedules. Use AutoCAD’s DATAEXTRACTION tool to export these attributes directly into CSV or XLS files. This makes managing parts lists easier and keeps your documentation up to date. You can also update these tables if your drawing changes, keeping everything synced.

Integrating with Other Autodesk Tools

Sometimes, you’ll want to prep your AutoCAD files further before sending them off for CNC machining. You can export directly to Autodesk Inventor or Fusion 360 for advanced 3D modeling and simulation. This integration streamlines complex CNC workflows, especially when dealing with 3D parts or assemblies, giving you more control over the final output.

Using these advanced export tips will make your AutoCAD file prep smoother and improve compatibility with CNC machining—and with HYCNC’s services.