Understanding the Passivation Process

Passivation is a critical chemical treatment that enhances the corrosion resistance of stainless steel by forming a protective layer on its surface. This process works by removing free iron and other contaminants, allowing the natural formation of a thin, invisible chromium oxide layer that shields the metal from rust and corrosion.

How Passivation Works

When stainless steel is exposed to air, a chromium oxide film forms naturally. However, manufacturing processes like cutting, welding, or machining can leave behind iron particles and residues that reduce this protective effect. Passivation cleans these impurities and accelerates the formation of the chromium oxide layer, restoring and improving corrosion resistance.

Key Steps in the Passivation Process

The passivation process generally follows a few essential steps:

- Cleaning: Remove oils, grease, and dirt from the stainless steel surface.

- Acid Treatment: Immerse or spray the metal with a passivating acid solution to dissolve free iron and contaminants.

- Rinsing: Thoroughly rinse with water to remove residual acids and residues.

- Drying: Dry the surface completely to ensure the new chromium oxide layer forms effectively.

Nitric Acid vs Citric Acid Passivation

Two acids commonly used in passivation are nitric acid and citric acid.

- Nitric acid passivation is traditional and widely used, offering effective removal of iron particles. It complies with industry standards like ASTM A967, but it is highly corrosive and requires careful handling.

- Citric acid passivation is a safer, environmentally friendly alternative that provides similar corrosion resistance without the harsh chemicals. It is increasingly preferred for applications requiring green processes and easier waste disposal.

Both methods improve stainless steel corrosion resistance but choosing between them depends on specific application needs, regulatory requirements, and environmental considerations.

For precision parts requiring both machining and surface treatment, our expertise in CNC machining combined with advanced passivation techniques ensures consistent, high-quality corrosion protection. Learn more about our materials and services related to stainless steel finishing in our mild steel tube resources.

Why Passivate Stainless Steel

Passivating stainless steel is all about boosting its natural ability to resist rust and corrosion. When stainless steel goes through passivation, it forms a thin, protective chromium oxide layer on the surface. This layer stops moisture and contaminants from causing damage, which means your stainless steel parts last longer and stay looking clean.

Benefits of Passivation

- Improved corrosion resistance: Passivation helps protect stainless steel from rust, especially in tough environments.

- Longer lifespan: The protective layer reduces wear and tear, keeping parts functional for years.

- Cleaner surface: Passivation removes free iron and other impurities, preventing surface staining.

- Better performance: When your stainless steel is passivated, it holds up better under stress and harsh conditions.

Common Applications

Passivation is widely used across industries, including:

- Medical equipment: Ensures tools and devices resist corrosion and stay sterile.

- Food processing: Keeps surfaces hygienic and corrosion-free.

- Aerospace and automotive: Protects parts exposed to extreme weather and conditions.

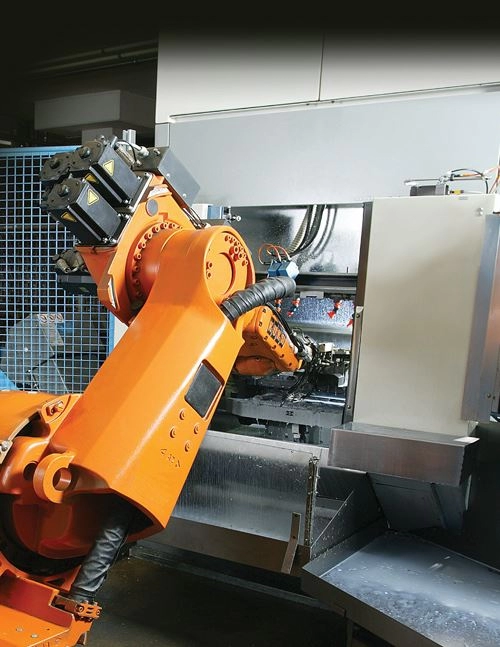

- CNC machining parts: Enhances the durability and finish of custom metal components.

When Is Passivation Necessary

You usually need to passivate stainless steel after:

- Machining or welding: These processes can leave iron particles or damage the protective layer.

- Surface finishing: Grinding or polishing might expose the metal to corrosion risks.

- Exposure to harsh environments: Saltwater, chemicals, or outdoor conditions can accelerate corrosion without passivation.

In short, passivation is a crucial step whenever you want to maintain stainless steel’s durability and corrosion resistance in the long run.

Industry Standards and Testing Methods

Key Standards for Passivation

When it comes to stainless steel passivation, following industry standards ensures consistent corrosion resistance and quality. In the U.S., the most recognized standards include ASTM A967 and AMS 2700. These standards outline the proper procedures for cleaning and passivating stainless steel to rebuild the crucial chromium oxide layer that protects the surface.

- ASTM A967 focuses on the accepted methods and requirements for chemical treatments, covering both nitric acid and citric acid passivation.

- AMS 2700 provides detailed passivation controls for aerospace-grade stainless steel, ensuring high reliability especially where corrosion resistance is critical.

Adhering to these standards helps prevent premature corrosion and extends the lifespan of stainless steel parts in various environments.

Testing Passivation Quality

After passivation, it’s essential to verify that the process was successful and that the stainless steel surface has adequate corrosion resistance. Common testing methods include:

- Water Break Test: A quick visual check to see if the surface repels water evenly, indicating a clean, passive surface.

- Copper Sulfate Test: Detects free iron contamination on the surface which can lead to rust if not removed.

- Salt Spray Test: Simulates harsh environments to check corrosion resistance over time.

These tests help ensure that stainless steel parts, especially those CNC machined and surface-finished, meet corrosion prevention requirements before reaching customers.

By following these standards and testing methods, manufacturers in the U.S. can deliver stainless steel products with reliable, long-lasting performance.

Challenges and Best Practices in Passivation

Common Challenges

Passivating stainless steel isn’t always straightforward. Here are some common hurdles we see:

- Surface Contamination: Oils, dirt, or machining residues can block the passivation process, leading to poor corrosion resistance.

- Improper Chemical Use: Using the wrong acid type or concentration (nitric vs citric) can weaken the chromium oxide layer instead of strengthening it.

- Incomplete Rinsing: Leftover chemicals on the surface can cause staining or speed up corrosion later on.

- Incorrect Timing: Too short or too long exposure to passivation acids can affect the quality of the protective layer.

- Inconsistent Inspection: Without proper testing, weak spots might go unnoticed and cause failure over time.

Best Practices for Effective Passivation

To get the best out of stainless steel passivation, follow these key tips:

- Clean Thoroughly First: Remove oils and debris completely before passivation begins.

- Choose the Right Acid: Nitric acid works well for many, but citric acid is a safer, environmentally friendly alternative that’s popular in US manufacturing.

- Follow Proper Standards: Stick to ASTM A967 or AMS 2700 guidelines for reliable results and consistent quality.

- Control Process Parameters: Monitor acid concentration, temperature, and timing closely to avoid damaging the steel surface.

- Rinse Properly: Use clean, deionized water to rinse thoroughly and prevent chemical residue.

- Test Passivation Quality: Perform regular checks using water-break tests or electrochemical methods to confirm the protective layer is intact.

By addressing these challenges and using proven best practices, you’ll boost corrosion resistance, improve stainless steel surface finishing, and extend the life of your parts — especially when paired with reliable CNC machining surface treatment.

Why Choose HYCNC for Stainless Steel Passivation

HYCNC’s Expertise in CNC Machining and Passivation

At HYCNC, we bring together advanced CNC machining and expert stainless steel passivation to deliver high-quality, corrosion-resistant parts. Our team understands that stainless steel surface finishing isn’t just about shaping metal—it’s about protecting it. We use proven passivation processes to enhance the chromium oxide layer on your parts, ensuring long-lasting corrosion resistance.

Benefits of Partnering with HYCNC

When you choose HYCNC, you get more than just machining services. We offer:

- Integrated CNC machining and passivation for streamlined surface treatment

- Compliance with key industry standards like ASTM A967 and AMS 2700 to guarantee quality

- Customized solutions tailored to your specific corrosion prevention needs

- Faster turnaround times without cutting corners on quality

- Local support that understands the requirements of U.S. industries

Our combined expertise saves you time and reduces risks, delivering parts ready to perform in demanding environments.

Case Study HYCNC’s Passivation Success

One recent project involved producing stainless steel components for a Midwest manufacturing client needing enhanced corrosion resistance. Through our careful application of citric acid passivation following CNC machining, we extended the parts’ lifespan significantly. The result was a reliable, high-performance product that reduced maintenance costs and met strict quality standards. This success highlights why customers trust HYCNC for both machining and stainless steel passivation.

Interested in learning about our CNC machining capabilities? Check out our detailed services on mild steel tube processing for more on how we handle various steel materials with precision.

FAQs

What is stainless steel passivation?

Passivation is a chemical treatment that removes free iron and contaminants from the stainless steel surface. This process boosts corrosion resistance by forming a protective chromium oxide layer.

Why is passivation important for stainless steel?

It helps prevent rust and corrosion, extending the life of stainless steel parts, especially in harsh environments or when high cleanliness is required.

How does nitric acid passivation compare to citric acid passivation?

Nitric acid passivation is traditional and effective but uses stronger chemicals. Citric acid is a safer, more environmentally friendly alternative with similar corrosion prevention results.

When should stainless steel be passivated?

Passivation is necessary after machining, welding, or whenever the surface has been exposed to contaminants that might reduce corrosion resistance.

What standards ensure quality passivation?

Key industry standards include ASTM A967 and AMS 2700, which outline proper procedures and testing to verify passivation quality.

Can CNC machining and passivation be combined?

Yes. After CNC machining stainless parts, passivation ensures the surface finishing enhances corrosion resistance and longevity.

For more information about related steel materials and surface treatments, check out our pages on mild steel tube and laser cut steel.