What Is a Tapped Hole in Machining

If you’ve ever wondered what exactly a tapped hole is in machining, you’re not alone. Simply put, a tapped hole is a pre-drilled hole in a metal or other material that has internal threads cut or formed inside it. These threads allow screws or bolts to securely fasten components together.

Definition

A tapped hole is created by cutting or forming internal helical grooves matching a specific thread size and pitch. This transforms a plain hole into one that can accept a threaded fastener, providing a strong, durable connection point in assemblies.

Difference with Threaded Holes

You might hear “tapped hole” and “threaded hole” used interchangeably, but here’s the nuance:

- Tapped Hole: Specifically refers to the hole after it has been drilled and internally threaded (typically by a tap tool).

- Threaded Hole: A broader term that includes tapped holes but also holes with threads formed by other means, like thread forming taps or inserts.

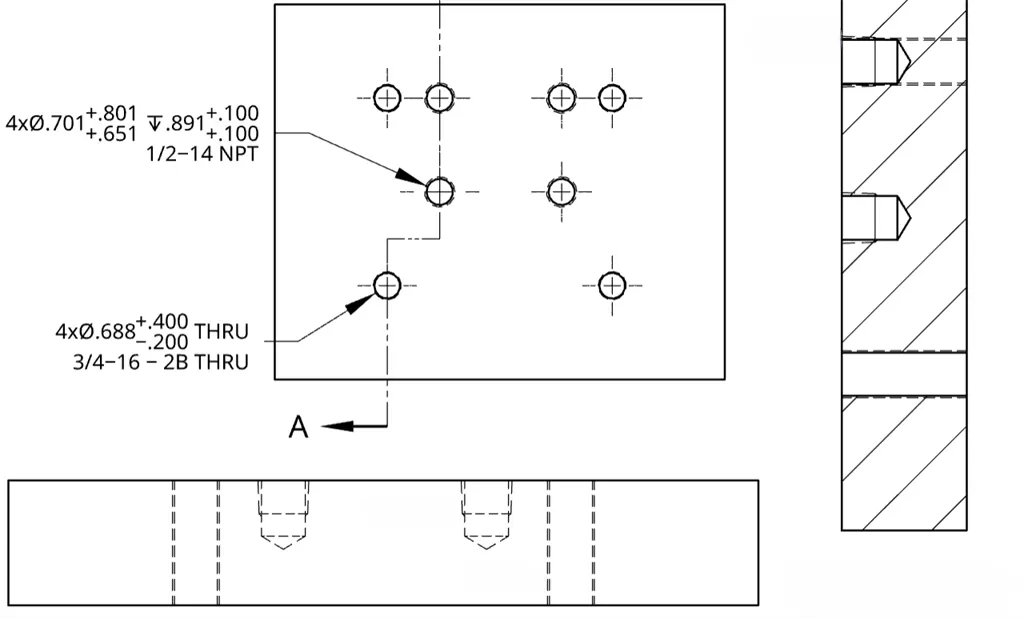

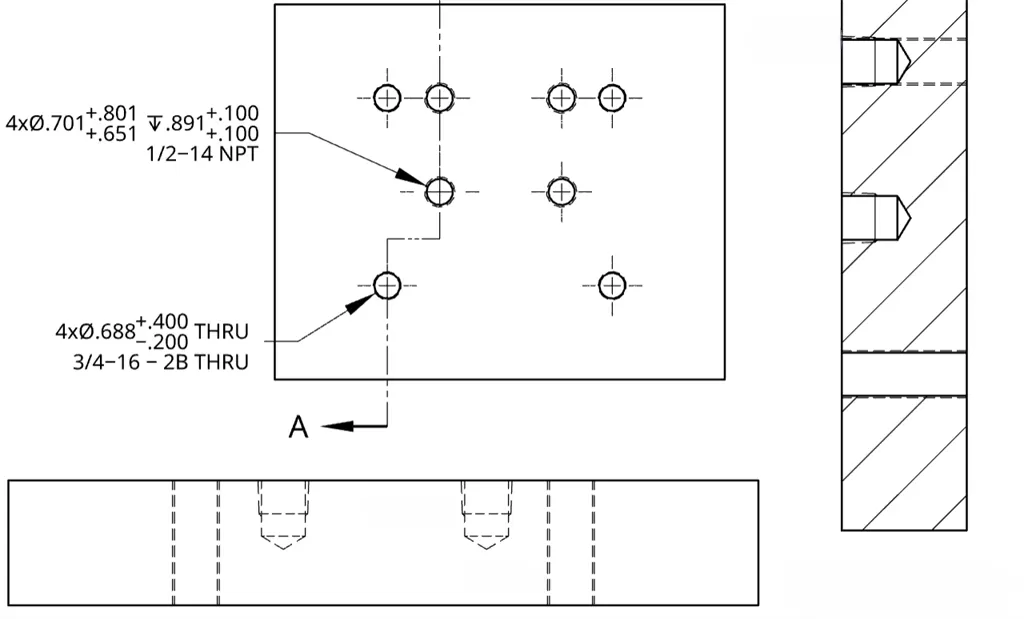

Key Characteristics

- Internal threads: Precise grooves inside the hole enabling screw engagement.

- Size specificity: Tapped holes are made to fit standardized fastener sizes based on thread standards.

- Strong fastening: They provide robust mechanical joints.

- Customizable depth: Can be through holes or blind holes, depending on design needs.

Understanding these basics helps when selecting the right approach for your project, whether for manual machining or CNC applications. For more on related CNC processes, check out our resource on what is CNC machining.

The Tapping Process How Tapped Holes Are Created

Creating tapped holes involves cutting internal threads into a pre-drilled hole, allowing screws or bolts to grip securely. Here’s a simple step-by-step guide to the tapping process:

-

Drill the Hole

Start by drilling a hole with the right diameter, usually based on a tap drill size chart. This ensures the threads will form correctly.

-

Choose the Tap

Pick the right tap for your material and thread standard. There are different types like taper taps or bottoming taps depending on the job.

-

Start Tapping

Insert the tap into the hole and begin turning it carefully, cutting threads as you go. Use cutting fluid if needed to reduce friction and improve thread quality.

-

Back Out and Clean

Reverse the tap every few turns to clear chips and prevent binding. Keep the hole clean to avoid thread damage.

Manual vs CNC Tapping

-

Manual Tapping

Done by hand, best for small jobs or prototypes. It requires steady hands and attention to avoid misalignment or tap breakage.

-

CNC Tapping

Automated tapping done by CNC machines offers higher precision and speed. It’s great for production runs and ensures consistent thread quality.

Importance of Alignment

Proper alignment during tapping is crucial. If the tap isn’t perfectly straight, threads can be uneven, causing fastener failure or stripped threads. Whether manual or CNC, always ensure the tap is aligned with the hole axis to get accurate, reliable internal threads.

Types of Taps and Their Applications

When it comes to creating tapped holes, using the right type of tap is key for a clean, strong thread. Here’s a quick overview of the common tap types and where you’d typically use them:

Common Tap Types

-

Taper Tap

Has a gentle taper, making it easier to start threading. Ideal for through holes or holes already drilled deeper than the tap length.

-

Plug Tap

Less tapered than taper taps, good for general-purpose threading in through holes. It balances ease of cutting and thread completeness.

-

Bottoming Tap

Designed for threading to the bottom of blind holes where the hole depth matches the thread length. Has almost no taper.

-

Thread Forming Tap

Instead of cutting, it displaces material to form threads. Best for ductile metals; it produces stronger threads and reduces chip buildup.

Material Considerations

Choosing the right tap depends on the material you’re tapping:

- Aluminum and softer metals: Thread forming taps work well because they minimize material removal and create strong threads.

- Steel and harder materials: Cutting taps like plug or taper taps are preferred to effectively remove chips and avoid tap breakage.

- Thin or brittle materials: Use taps with specialized coatings or precise geometry tailored to reduce stress and prevent damage.

Thread Standards

Tapped holes need to match specific thread standards for compatibility and strength. The most common standards include:

- Unified Thread Standard (UTS): Common in the U.S. for inch-based threads, used widely in automotive and manufacturing.

- Metric Thread Standard: Standard in international applications, using metric measurements.

- Specialty Threads: Such as Acme or pipe threads, used for specific mechanical or fluid sealing purposes.

Knowing the right tap type, material compatibility, and thread standard helps ensure your tapped holes meet the requirements for strength, fit, and performance.

For more on thread sizing and standards, check out our guide on threaded hole machining.

Benefits of Tapped Holes in CNC Machining

Tapped holes offer several key benefits that make them essential in precision CNC machining. Here’s why they matter:

Secure Fastening

Tapped holes provide strong internal threads, ensuring bolts and screws stay firmly in place. This secure hold is crucial for parts that experience vibrations or heavy loads.

Versatility

They can be customized for various thread sizes and types, making them useful across different materials and applications. Whether you need coarse or fine threads, tapped holes handle the job.

Space Efficiency

Compared to adding nuts or external threading, tapped holes save space in tight assemblies. This efficient use of space is ideal for compact designs common in automotive or aerospace parts.

Ease of Assembly

With tapped holes, assembly becomes quicker and simpler. Fasteners can be installed or removed easily without the need for extra components, speeding up maintenance and production.

Cost-Effectiveness

CNC tapping adds minimal manufacturing time, reducing overall costs. Plus, the reliability of tapped holes minimizes future repairs or replacements, making them a smart investment for long-term use.

These benefits highlight why tapped holes are a staple in CNC machining processes. For more about CNC techniques, check out our guide on what is CNC machining.

Applications of Tapped Holes Across Industries

Tapped holes play a vital role in many industries here in the U.S., offering strong, reliable fastening solutions wherever needed.

-

Automotive: From engine assembly to chassis construction, tapped holes provide secure attachment points for bolts and screws, ensuring parts stay together under high stress and vibration.

-

Aerospace: Precision and safety are critical. Tapped holes are used in aircraft components for lightweight but durable fastenings that hold together sensitive parts without compromising structural integrity.

-

Manufacturing: Tapped holes are everywhere—from heavy machinery to smaller industrial equipment. They help in assembling parts efficiently and allow for easy maintenance or replacement of components.

-

DIY and Prototyping: For hobbyists and engineers, tapped holes offer a convenient way to build prototypes or custom projects. They make it easy to fasten pieces reliably without complicated setups.

-

HYCNC Precision Delivery: At HYCNC, we specialize in precision CNC machining, ensuring every tapped hole meets exact specifications. Our CNC tapping process guarantees alignment, clean threads, and consistent quality—perfect for your production or prototyping needs.

No matter the project, tapped holes deliver versatility and strength across industries—something every U.S. manufacturer and builder depends on.

Challenges and Best Practices for Tapped Hole Machining

Tapped hole machining comes with its share of challenges, but knowing these upfront can save a lot of time and material.

Common Challenges

- Breakout or burrs: When the tap breaks through the bottom of the hole, it can cause rough edges or damage.

- Misalignment: Poor alignment leads to uneven threads, reducing fastening strength.

- Tool wear: Taps can dull quickly, especially with harder materials, affecting thread quality.

- Chip clogging: Metal chips can get stuck in the tap, causing jams or poor thread cutting.

- Tap breakage: Applying too much force or using the wrong tap can snap the tool inside the hole.

Best Practices

- Use the right tap drill size chart to pre-drill holes at the correct diameter.

- Choose taps suited for the material (e.g., thread forming taps for aluminum, cutting taps for steel).

- Maintain proper lubrication to reduce heat and wear.

- Ensure the hole is clean and free of debris before tapping.

- Use sharp, quality taps and replace them regularly to maintain precision.

- For CNC tapping, verify machine alignment and use the correct feed rate.

- When manually tapping, back off occasionally to clear chips and avoid binding.

Tips for Avoiding Breakout

- When tapping bottom holes, use bottoming taps carefully to control thread depth without going through.

- Avoid excessive feed pressure as it puts stress on the tap and material.

- Consider using a chamfer or countersink before starting the thread to guide the tap easily.

- Run test taps on scrap material to dial in speeds and feeds especially on unfamiliar materials.

Following these tips helps ensure clean, strong tapped holes that hold up in real-world applications across industries.

Tapped Holes vs Threaded Holes Key Differences

Tapped Holes Overview

A tapped hole is a hole drilled into a material that is then cut internally with threads using a tap. This allows bolts or screws to be fastened directly into the material without needing a nut. Tapped holes are common in CNC machining for creating strong, reusable connection points without extra hardware.

Threaded Holes Overview

Threaded holes, on the other hand, can refer more broadly to any hole with internal threads, including those created by tapping or by threading inserts like helicoils. Threaded holes might also include holes with pre-installed threaded inserts or thread forming taps used to displace material instead of cutting it.

Key Differences Table

| Feature | Tapped Holes | Threaded Holes |

|---|---|---|

| Creation Method | Cut with a tap inside a drilled hole | Often tapped or use threaded inserts |

| Requires Nuts | No | Sometimes, depending on application |

| Strength and Durability | Strong in standard materials | Can be reinforced with inserts |

| Flexibility | Limited to material’s thread strength | Inserts allow repair or upgrade |

| Common Use | Direct fastener connection | Can be for heavy-duty or repair tasks |

When to Choose Tapped Holes

- You want a clean, straightforward fastening method without additional parts.

- Space is tight, and using a nut is impractical.

- The base material is strong enough to hold a thread reliably.

- You need cost-effective, fast assembly in CNC machining projects.

For more on thread standards in machining and how tapped holes fit into precision work, check out our precision machining services and explore the basics of CNC machining to see how these holes come together in real-world applications.

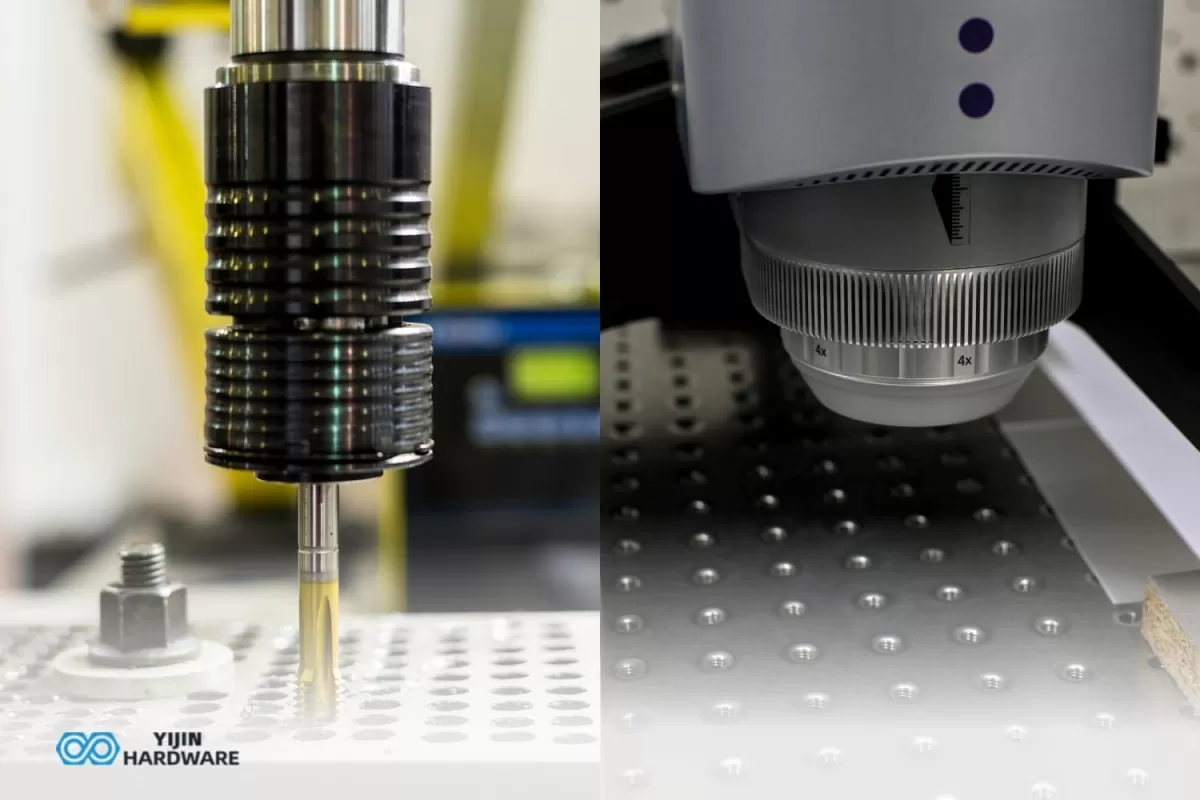

How HYCNC Ensures Precision in Tapped Hole Machining

At HYCNC, precision is at the heart of everything we do, especially when it comes to tapped hole machining. Our advanced CNC capabilities allow us to create highly accurate internal thread cutting, ensuring every tapped hole meets tight tolerances. Whether you need standard thread sizes or custom threads, our machines deliver consistently clean and precise results.

We don’t just rely on equipment — our strict quality control process keeps every tapped hole in check. From initial setup to final inspection, we use detailed measurements and thread standards in machining to guarantee reliable and defect-free threaded holes.

Every project is unique, so we offer custom solutions tailored to your specific needs, including choosing the right tap types like taper taps or thread forming taps. This flexibility helps us handle a wide range of materials and applications, from aerospace parts to automotive components.

If you’re looking for top-notch CNC machining services focused on tapped holes, HYCNC is ready to deliver precision and reliability every time. Contact us today to discuss your project and see how we can help you get the perfect tapped holes for your parts.