Are you torn between spot welding and tack welding for your next fabrication project? Choosing the right welding technique can make or break your project’s quality and efficiency. As experts in CNC machining and metal fabrication, we at HYCNC understand the importance of picking the perfect method for your needs. In this guide, we’ll break down the key differences, applications, and advantages of spot weld vs tack weld, giving you clear, actionable insights to ensure success. Dive in to discover which technique is right for you!

What is Spot Welding

Definition

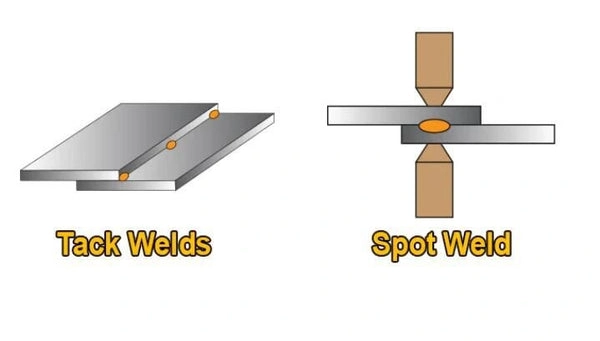

Spot welding, also known as resistance spot welding, is a metal joining method that uses heat generated by electrical resistance to fuse two or more metal sheets at localized points. This process involves pressing electrodes on either side of the materials and passing a high current through them, which creates heat and welds the metals together at these specific spots.

Process

The spot welding process is quick and efficient:

- Metal sheets are clamped between two copper alloy electrodes.

- A strong electrical current flows through the electrodes, heating the metal where they contact due to resistance.

- The heat melts the metal locally, creating a weld nugget as the materials fuse.

- The weld solidifies under pressure when the current is turned off.

This precise control prevents excessive heat spread, reducing distortion and damage to surrounding areas.

Applications

Spot welding is commonly used in manufacturing where rapid, strong joints are required, especially in:

- Automotive industry for assembling car bodies and frames.

- Sheet metal fabrication for household appliances.

- Electrical equipment manufacturing.

It’s ideal for joining thin sheets of steel or aluminum where multiple weld spots create a strong, uniform bond.

Advantages

- Speed: Very fast process ideal for mass production.

- Cost-effective: Minimal consumables and energy-efficient.

- Consistent quality: Provides reliable, repeatable welds.

- Clean and precise: No filler materials or gases needed means fewer contaminants.

- Minimal distortion: Localized heat reduces warping of thin sheets.

Disadvantages

- Limited thickness: Best suited for thin sheets; thicker metals may require other techniques.

- Material restrictions: Works primarily on conductive metals like steel and aluminum.

- Equipment cost: Initial investment in spot welding machines can be high.

- Surface preparation: Requires clean, smooth surfaces for optimal weld quality.

- Access constraints: Electrodes must have direct access to weld area, limiting flexibility for complex shapes.

Spot welding remains a staple in industries where speed and precision matter, especially when working with lightweight sheet metal assemblies.

What is Tack Welding

Definition

Tack welding is a technique where small, temporary welds hold metal pieces together in place before the final welding process. Think of it as a quick, light stitch to keep parts aligned during assembly.

Process

During tack welding, a welder applies short bursts of heat to create tiny weld spots at key points. This holds the materials steady while allowing for adjustments before completing the full weld. It’s commonly done with MIG, TIG, or stick welding equipment depending on the project.

Applications

Tack welding is widely used in metal fabrication and automotive repairs to position components accurately. It’s great for sheet metal joining, frame assembly, or anytime you need to hold parts temporarily without full fusion.

Advantages

- Keeps parts aligned and stable during setup

- Allows for easy corrections before permanent welding

- Saves time in complex assemblies

- Minimal heat distortion compared to continuous welds

Disadvantages

- Tack welds are not designed for strength; they can break under stress

- Poor quality tacks may cause gaps or weak points if not replaced with full welds

- Requires follow-up welding for a permanent join

- May slow down workflow if used excessively or improperly

Tack welding is a handy, temporary weld solution that plays a crucial role in keeping metal parts in place before the final, stronger welds are applied.

Key Differences Between Spot Welding and Tack Welding

Purpose

Spot welding is designed to create strong, permanent joints by fusing metal sheets together at specific points. It’s commonly used for final assembly in industries like automotive and sheet metal fabrication. Tack welding, on the other hand, is mostly a temporary weld used to hold parts in place before the full weld is completed. It helps with alignment and prevents movement during the welding process.

Equipment

Spot welding relies on resistance spot welding machines. These use electrodes to pass current through metal sheets, generating heat to fuse them. Tack welding can be done using various welding methods, including MIG, TIG, or stick welding, depending on the material and application. The equipment for tack welds is usually more versatile but less specialized than spot welding machines.

Material Compatibility

Spot welding works best on thin sheets of metal like steel or stainless steel, often 0.5 mm to 3 mm thick. It requires materials that conduct electricity well for effective heat generation. Tack welding is more flexible with materials and thicknesses since it’s a manual process and can be adjusted depending on the welding method used.

Speed and Automation

Spot welding is fast and easily automated, making it ideal for high-volume production lines like automotive manufacturing. Its process is repeatable and consistent. Tack welding is generally slower and manual, suited for smaller projects or where precise positioning of parts is needed before full welding.

Strength

Spot welds provide a solid, permanent connection with high shear strength, suitable for load-bearing joints. Tack welds are weaker by design since they act as placeholders; they are not intended to carry structural loads on their own.

Table Comparison

| Feature | Spot Welding | Tack Welding |

|---|---|---|

| Purpose | Permanent joints | Temporary alignment |

| Equipment | Resistance spot welding machine | MIG, TIG, Stick welders |

| Material Compatibility | Thin sheet metals, conductive | Various metals, flexible |

| Speed | Fast, automated | Slower, manual |

| Strength | High, permanent | Low, temporary |

| Typical Application | Automotive, mass production | Fabrication setups, fit-up |

These differences show why spot and tack welding each have their place in metal fabrication. Choosing between them depends on your project’s goals, materials, and workflow.

For more on welding quality and avoiding defects, check out this detailed guide on solutions to common defects in spot welding and tips on preventing cracking in tack welds.

When to Use Spot Welding vs Tack Welding

Spot Welding

Spot welding is your go-to when you need a strong, permanent bond between sheet metals, especially in automotive and appliance manufacturing. It works best on thinner metals like steel and stainless steel. Use spot welding when speed and production automation matter because it’s fast and often automated, making it perfect for large-scale projects. If your goal is to join parts firmly and cleanly with minimal distortion, spot welding is the right choice.

Tack Welding

Tack welding shines when you need to hold metal pieces temporarily in place before final welding. It’s commonly used during the fit-up phase in fabrication or metal assembly to ensure alignment. Tack welds are smaller, quicker, and easier to remove if adjustments are needed. Use tack welding for complex assemblies, larger materials, or when you want to reduce welding distortion by controlling heat input. It’s practical for situations where precision and the option to reposition are key.

Case Study How HYCNC Uses Precision CNC Machining

At HYCNC, precision CNC machining plays a vital role in improving both spot welding and tack welding results. By delivering accurate, laser-cut parts and precisely located features, CNC machining ensures perfect fit and alignment before welding. This reduces errors and the need for rework, minimizing distortion and improving weld quality.

For example, when fabricating automotive parts, HYCNC’s CNC services help align components precisely, so spot welds can be placed consistently. For tack welds, precise machining allows temporary joints that hold tight, making the final welding process smoother and more efficient.

Learn more about improving weld fit-up with CNC machining here: Save Time with Locating Features for Weldments

How HYCNC Enhances Welding with CNC Precision

At HYCNC, we take welding to the next level by combining precision CNC machining with expert welding techniques. Using advanced CNC equipment, we ensure every part is cut and shaped with perfect accuracy before it reaches the welding stage. This exact fit means welds are stronger, cleaner, and more consistent.

Here’s how HYCNC’s CNC precision helps improve welding outcomes:

- Better Weld Alignment: Accurate parts reduce gaps and misalignment, making spot welds and tack welds more reliable and easier to perform.

- Less Weld Distortion: CNC cutting produces uniform edges, minimizing heat distortion during welding, which keeps the metal stable.

- Faster Production: Precise components speed up welding setups and reduce rework, saving time and cost.

- Consistent Quality Control: Repeatable CNC processes ensure every piece meets tight tolerances, so the welding joints hold up under stress.

For industries like automotive and sheet metal fabrication, where strength and accuracy are critical, HYCNC’s integration of CNC machining with welding services delivers superior craftsmanship in every job. It’s a practical way to boost quality, reduce waste, and keep projects on track.

Practical Considerations for Choosing Between Spot and Tack Welding

When deciding between spot weld vs tack weld, several practical factors come into play. Understanding these will help you pick the best method for your project.

Cost

Spot welding usually requires specialized resistance welding machines, which can be pricey upfront but cost-effective for large production runs. Tack welding needs less equipment investment, making it more budget-friendly for small projects or repairs.

Skill Level

Spot welding is more automated and consistent, so it often needs less manual skill once the setup is done. Tack welding, however, depends heavily on the welder’s hands-on ability to place strong, accurate tacks to hold parts together before final welding.

Project Scale

For high-volume jobs like automotive or sheet metal fabrication, spot welding is ideal because it’s fast and repeatable. Tack welding shines in smaller projects, prototype work, or where parts need to be held temporarily before full welding.

Material Type

Spot welding works best with thin sheet metals and compatible materials like steel and aluminum alloys. Tack welding is more versatile and can be used on thicker metals or when joining dissimilar materials while prepping for further welding.

Quality Control

Because spot welding is highly consistent and automated, it offers better repeatability and less weld distortion, helpful in automotive welding and other precision sheet metal joining. Tack welding requires careful inspection since weak or poorly placed tacks can lead to warping or misalignment before permanent welding.

Choosing the right welding method depends on balancing cost, skill, scope, material, and quality needs to ensure efficient and strong fabrication.

Common Mistakes to Avoid

Spot Welding

- Overheating the metal: Applying too much current or holding the electrodes too long can burn through thin sheets, causing weak or damaged welds.

- Poor electrode maintenance: Dirty or worn electrodes reduce weld quality and consistency. Make sure to clean and dress electrodes regularly.

- Incorrect pressure: Too little pressure causes weak joints; too much can deform the parts. Getting the right balance is key.

- Misalignment: If the sheets aren’t properly aligned, the weld won’t hold well, leading to structural problems.

Tack Welding

- Using tack welds as permanent joints: Tack welds are meant to hold parts temporarily for alignment or fitting before the final weld. Relying on tack welds alone can lead to weak joints.

- Uneven tack spacing: Placing tacks too far apart can allow parts to shift during final welding, resulting in poor fit or distortion.

- Excessive heat input: Too much heat can warp thin materials or cause burn-through.

- Ignoring weld size: Tack welds should be just big enough to hold parts; making them too large wastes time and material.

Tips for Success

- Clean your workpieces: Removing rust, dirt, and oil ensures better weld quality.

- Use the right equipment settings: Match current, pressure, and duration to the materials and thickness.

- Keep parts aligned: Whether spot welding or tack welding, good fit-up is crucial.

- Regularly maintain your tools: Check electrodes for wear and replace when needed.

- Practice welds: Especially with tack welding, practice helps control heat and placement.

Following these points helps prevent common issues so your welds come out strong and reliable every time.

FAQs

What is the main difference between spot welding and tack welding

Spot welding uses electric resistance to join two metal sheets permanently at small points. Tack welding, on the other hand, creates temporary welds to hold parts in place before completing the full weld. So, spot welding is for final bonds, while tack welding is mostly for positioning and alignment.

Can tack welds be used as permanent welds

Technically, yes, but it’s not recommended. Tack welds don’t have the strength or durability of full welds like spot welding. They’re great for holding parts temporarily during assembly but usually need to be replaced by stronger welding later.

Which welding method is better for automotive applications

Spot welding is the go-to for automotive manufacturing, especially for joining sheet metal in car bodies. It’s fast, consistent, and works well with metals used in vehicles. Tack welding is used for fitting parts quickly and aligning panels before the final spot welds.

How does HYCNC’s CNC machining improve welding outcomes

HYCNC’s precision CNC machining ensures perfectly cut and aligned parts. This tight fit reduces weld distortion, improves weld quality, and speeds up both spot and tack welding processes. Their CNC services help metal fabricators achieve exact tolerances, which is crucial for high-quality welds.

What materials are best suited for spot welding vs tack welding

Spot welding works best on thin sheet metals like steel and aluminum often used in automotive and appliance industries. Tack welding is more flexible and works on a broader range of materials including thicker metal sections and mixed metals as a temporary join during fabrication.