Why Choose Fastener-Free Joining for Laser Cut Parts

Wondering why skip screws, bolts, or glue when joining laser cut parts? Fastener-free joining offers some solid benefits.

Cost Efficiency

You save money by cutting out screws, bolts, or adhesives. No extra hardware means fewer expenses and less waste.

Aesthetic Appeal

Without visible fasteners, your designs look cleaner and more seamless. This is perfect for sleek, modern projects where every detail counts.

Time Saving

Assembly becomes much quicker and easier. Whether you’re a DIYer or a pro, fastener-free joints speed up your build and reduce frustration.

Material Versatility

These methods work well across a range of materials—metals, wood, acrylic, and more—giving you creative freedom.

Real Results

At HYCNC, many clients achieve smooth, professional results using fastener-free joining techniques. Their projects look sharp, sturdy, and polished without the clutter of hardware.

Fastener-free joining isn’t just a neat trick—it’s practical, stylish, and efficient for your laser cut projects.

Top Fastener-Free Joining Techniques for Laser Cut Parts

Tab-and-Slot Joints

Tab-and-slot joints use interlocking tabs and slots to create strong, secure connections. They’re best for materials like sheet metal, wood, and acrylic, especially if your material is 0.080 inches thick or more.

Design tips:

- Make tabs about 50% of the material’s thickness

- Account for laser kerf by reducing slot sizes by 0.008 to 0.015 inches

Pros: Strong and easy to put together

Cons: Only work well along flat edges

Snap-Fit Joints

Snap-fit joints rely on elastic latches or hooks that snap into place, making assembly quick and often reversible. These are great for flexible materials such as thin aluminum or plastics.

Design tips:

- Design hooks with notches matching your material’s thickness

- Test how much your parts deflect to avoid breakage

Pros: Fast assembly and can be taken apart

Cons: Need really precise dimensions for a good fit

Finger Joints

Finger joints use interlocking fingers to join pieces at right angles, ideal for wood, acrylic, or other rigid materials.

Design tips:

- Adjust slot widths to include laser kerf

- Use dogbone fillets on corners to avoid sharp angles that can snag or weaken the joint

Pros: High strength and accuracy

Cons: Can be tricky for beginners to design

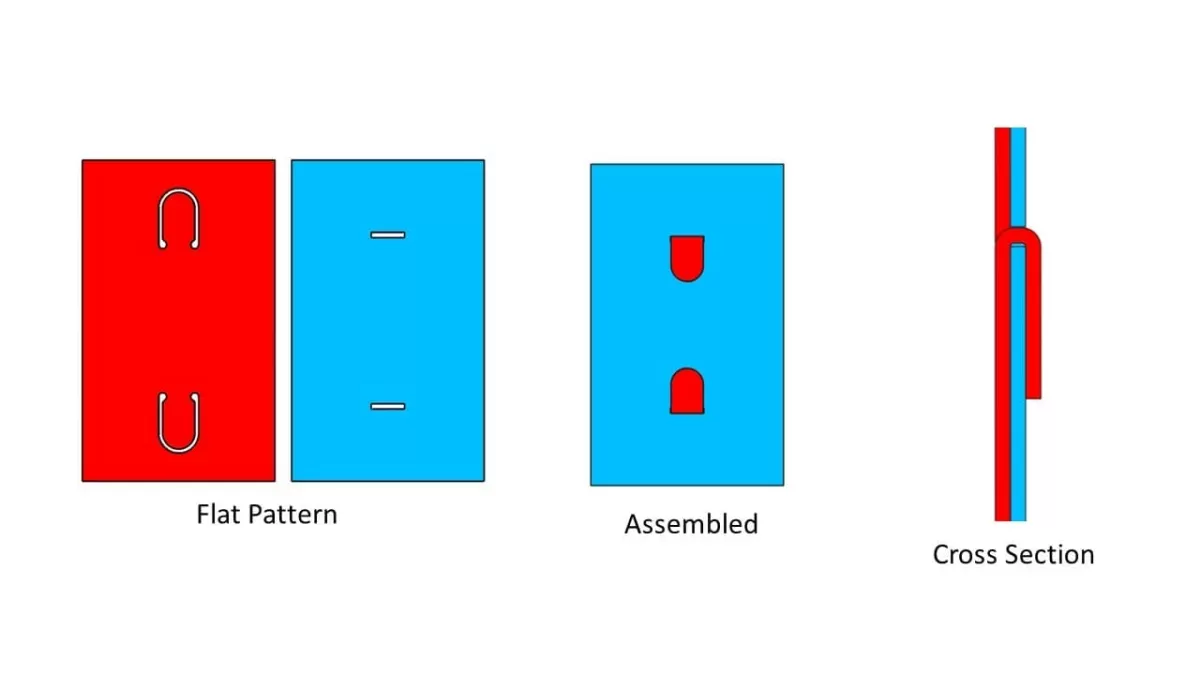

Bent Tab Joints

Bent tab joints involve folding tabs after fitting them through slots, creating permanent or semi-permanent connections. They’re perfect for thin metals like 2024 or 5052 aluminum.

Design tips:

- Add small holes at tab ends to make bending easier

- Use pliers for precise bends

Pros: Versatile and lasting joints

Cons: Not as strong when pulling parallel to the bend

Hammer Joints

Hammer joints are wedge-driven tenon and mortise connections mostly used for wood, especially in furniture or plywood sculptures.

Design tips:

- Design smooth, continuous outer contours for a tight fit

- Replicate these shapes accurately in your CAD file

Pros: No glue or fasteners needed, and parts are recyclable

Cons: You’ll need a hammer or mallet to assemble

Each method offers unique benefits depending on your material and project needs. Choosing the right fastener-free joint along with precise laser cutting will help you get seamless, professional results.

Design Considerations for Fastener-Free Joints

When designing fastener-free laser cut joints, keeping a few key points in mind can make a big difference.

- Account for laser kerf: The laser removes a small amount of material during cutting, so you need to reduce slot sizes for a tight fit. For example, subtract about 0.1 mm for a 3 mm thick material to avoid loose joints.

- Consider material thickness: Thicker materials (0.080 inches and up) work best with tab-and-slot joints, while thinner sheets are better suited for bent tab designs.

- Test fit before final assembly: Always do a dry run to check alignment and tolerances. This helps catch any issues early.

- Use proper file formats: Submit vector files like DXF, AI, or EPS when ordering laser cutting from HYCNC. These formats ensure precise cuts and cleaner joints.

- Keep designs simple: Avoid overly detailed or fragile shapes to prevent material deformation or burn marks during cutting.

These steps help ensure your laser cut parts fit perfectly and create strong, seamless fastener-free joints.

Step-by-Step Guide to Designing Fastener-Free Joints

Step 1: Choose Your Material

Pick the right material based on your project — aluminum, wood, acrylic, or something else. Think about strength, flexibility, and appearance.

Step 2: Select the Joint Type

Decide on a joint style that fits your material and strength needs. Options include tab-and-slot, snap-fit, finger joints, bent tabs, or hammer joints.

Step 3: Design in CAD Software

Use AutoCAD, Onshape, or similar CAD tools to create your design. Don’t forget to adjust for laser cutting kerf — typically reducing slot sizes slightly to get tight fits.

Step 4: Upload Your Design to HYCNC

Submit your CAD file (DXF, AI, or EPS formats) to HYCNC’s instant quoting tool. Their precision CNC service will handle the laser cutting with quick turnaround.

Step 5: Test and Finalize

Assemble the parts to check fit and alignment. Make any needed tweaks before final production for smooth, fastener-free assembly.

Common Challenges and How to Overcome Them

When working with fastener-free laser cut joints, a few common issues can pop up. Here’s how to handle them:

-

Burned edges

Laser cutting can sometimes leave dark, burned edges that affect joint fit and appearance. Lightly sand these areas with 80-grit sandpaper, then clean with a solvent like isopropyl alcohol. This helps ensure smooth, clean joints that fit well.

-

Loose joints

If parts don’t fit snugly, it’s often due to not compensating properly for laser kerf. Adjust your slot sizes by reducing them slightly, usually about 0.1 mm for 3 mm thick material, or tighten your design tolerances to get a better fit.

-

Material limitations

Some joints don’t work well with very thin materials. For example, finger joints require at least 0.080 inches thickness. For thinner sheets, bent tab joints can be a stronger alternative.

-

Assembly errors

Misplacing parts or mixing components leads to wasted time or failed assemblies. Keep your workspace organized, label each part clearly, and follow a checklist to avoid mix-ups.

By anticipating these challenges and making simple adjustments, you can get strong, hassle-free fastener-free laser cut joints every time.

Why Choose HYCNC for Your Laser Cut Projects

When it comes to laser cut parts, precision matters—and that’s where HYCNC shines. Their laser cutting services deliver seamless, fastener-free parts with tight tolerances, making assembly easier and designs cleaner. Whether you’re working with metals, wood, or acrylic, HYCNC supports a wide range of materials and thicknesses perfect for tab-and-slot, snap-fit, and other fastener-free joints.

They also offer instant quoting on your designs, so you can get fast, transparent pricing without any guesswork. Plus, with turnaround times as quick as 2 to 4 business days, your project keeps moving without delays.

Ready to experience quality laser cut parts built for easy assembly? Upload your design to HYCNC’s platform today for a free, no-obligation quote and get started on your next project.

For more insight on laser cutting and design tips, check out design tips for CNC milled low volume parts.

FAQs

What materials work best for fastener-free laser cut joints

Materials like wood, acrylic, and thin sheet metals (such as aluminum) work great for fastener-free joints. Each material suits different joint types—acrylic and wood are ideal for finger and tab-and-slot joints, while thin metals are perfect for bent tab and snap-fit joints. For detailed info on laser cut aluminum, check out HYCNC’s laser cut aluminum materials guide.

How do I account for laser kerf in my designs

Laser kerf is the width of material the laser removes during cutting. You should reduce slot sizes and adjust tabs by about 0.1 mm for every 3 mm of material thickness to ensure a tight fit. Always test fit your parts, and consider kerf compensation when designing in CAD software.

Can snap-fit joints be used for metal parts

Yes, snap-fit joints can be used with flexible thin metals like aluminum, but they require precise tolerances and careful design because metals don’t flex like plastics. Make sure to test the deflection and fit before final cutting.

What tools do I need for assembling bent tab joints

You’ll mainly need pliers or small bending tools to fold the tabs after insertion. Sometimes, adding small holes at tab ends makes bending easier. For precise bends, use needle-nose pliers or specialized sheet metal bending tools.

How can HYCNC help with my laser cutting project

HYCNC offers precise laser cutting with quick turnaround times, supporting a wide range of materials and thicknesses ideal for fastener-free joints. Their instant quoting tool makes it easy to upload your design and get started. Whether it’s tabs, snap-fits, or finger joints, HYCNC helps bring your seamless laser cut designs to life efficiently.