What is Blind Riveting Definition and Mechanism Key Features Applications

Have you ever needed to fasten materials where you only have access to one side? That’s where blind riveting comes into play. Blind riveting, commonly known as pop riveting, is a mechanical fastening technique used when the back of the joint is inaccessible.

Definition and Mechanism

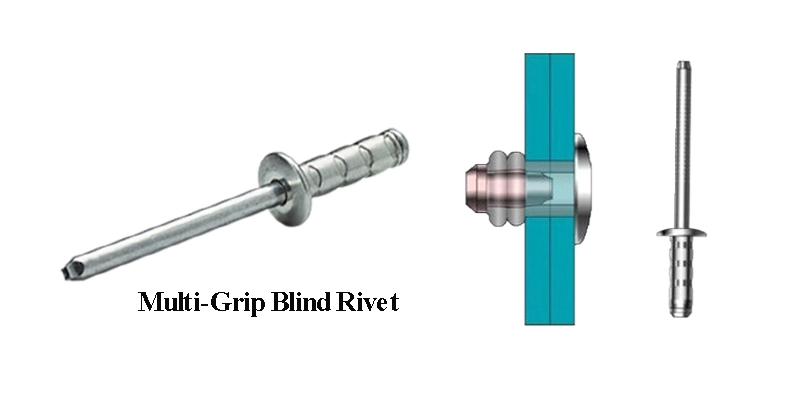

Blind riveting involves inserting a hollow rivet with a mandrel through pre-drilled holes in the materials to be joined. Using a specialized rivet installation tool or pop rivet gun, the mandrel is pulled, expanding the rivet body and pressing it firmly against the materials. Once the rivet deforms and clamps the materials, the mandrel breaks off, leaving a secure joint.

Key Features

- Access from One Side Only one side of the workpiece is needed, making it perfect for enclosed or hard-to-reach spaces.

- Quick Installation Rivets can be set rapidly with hand tools or pneumatic tools, boosting productivity.

- Wide Material Compatibility Commonly used on metals, plastics, and composites.

- Corrosion Resistance Available in aluminum, stainless steel, and other corrosion-resistant materials.

- Vibration and Shock Resistance The blind rivet provides steady, reliable fastening under stress.

Applications

Blind riveting is widely used across industries, including:

- Automotive Fastening panels and components where backside access is limited.

- Aerospace Attaching thin sheet metal panels and lightweight assemblies.

- Construction Joining sheet metal, roofing, and cladding materials.

- Electronics and Appliances Fastening enclosures and housings efficiently.

- Sheet Metal Fabrication Ideal for CNC machining fasteners in complex assemblies where speed and accessibility matter.

Blind rivets offer a practical and versatile solution when traditional solid riveting is not possible. Companies like HYCNC provide specialized CNC services to manufacture high-quality blind rivets suited for demanding applications in the US market.

What is Solid Riveting

Solid riveting is a traditional mechanical fastening method that uses a solid metal pin called a rivet to join two or more materials together. Unlike blind riveting, solid rivets require access to both sides of the materials being joined for installation. The rivet is inserted through aligned holes in the workpieces and then deformed or “upset” at the tail end by hammering or pressing to create a strong, permanent joint.

Mechanism

The solid rivet works by expanding the tail end to form a second head, locking the materials tightly together. This deformation process typically requires specialized tools such as pneumatic hammers, bucking bars, or CNC riveting machines. The solid nature of the rivet makes the joint exceptionally strong and resistant to shear and tensile forces.

Key Features

- Requires access to both sides of the workpieces

- Creates very strong, permanent joints

- Usually made from aluminum, steel, or copper alloys

- Can handle high-stress and heavy-duty applications

- Installation often involves specialized equipment

Applications

Solid riveting is widely used where maximum strength and durability are critical. Typical industries include:

- Aerospace: fastening aircraft skins and components

- Automotive: chassis and frame assembly

- Structural steel: bridges and heavy machinery

- Shipbuilding: hull and deck riveting

This method is preferred in applications where reliability and long-lasting joints matter most, especially in structural and safety-critical parts.

Blind Riveting vs Solid Riveting Key Differences

When it comes to choosing between blind riveting and solid riveting, understanding their core differences helps you pick the right fit for your project.

Installation Process

- Blind Riveting: Uses pop rivets that can be installed from one side of the workpiece, making it perfect when you don’t have access to both sides. The process is quicker and requires less specialized skill.

- Solid Riveting: Needs access to both sides because you have to hammer or press the rivet to form a strong joint. It takes more time and usually requires experienced hands or machines.

Strength and Durability

- Solid Rivets offer higher strength and are more durable, especially for heavy-duty applications like aerospace and automotive structural riveting. They handle stress and vibration better.

- Blind Rivets are generally less strong but good enough for lighter or medium-duty loads where ease of installation is a priority.

Cost and Efficiency

- Blind Riveting tends to be more cost-effective considering installation time and labor, especially for jobs where speed matters. Rivet installation tools for blind rivets are often simpler and less expensive.

- Solid Riveting can be costlier due to labor intensity, tooling, and sometimes the need for CNC machining fasteners or specialized equipment.

Accessibility and Versatility

- Blind Rivets excel in tight spaces or when only one side is accessible, making them very versatile across industries like sheet metal fabrication and general mechanical fastening.

- Solid Rivets are best if you need superior strength and have easy access to both sides of the material.

Quick Comparison Table

| Feature | Blind Riveting | Solid Riveting |

|---|---|---|

| Installation Method | One-sided | Two-sided |

| Strength | Moderate | High |

| Equipment Needed | Simple rivet gun | Hammer or press, skilled labor |

| Speed | Fast | Slower |

| Typical Applications | Sheet metal, automotive | Aerospace, heavy machinery |

| Cost | Lower installation cost | Higher installation cost |

| Accessibility | Fits tight or single-side access | Requires both sides access |

In , blind riveting is your go-to for quick, efficient fastening when access is limited. Solid riveting is the choice for strong, long-lasting joints, especially in demanding industries. Your project needs and budget will guide the best option.

Advantages and Disadvantages of Blind Riveting and Solid Riveting

Blind Riveting Advantages

- Easy Installation: Can be installed from one side, perfect for tight or hard-to-reach spots.

- Fast Process: Requires less time and skill compared to solid riveting, ideal for quick assembly.

- Versatile: Works well on a variety of materials like aluminum, steel, and plastic.

- Good for Thin Materials: Less risk of damaging thin sheets during installation.

Blind Riveting Disadvantages

- Lower Strength: Not as strong or durable as solid rivets for heavy-duty structural use.

- Potential for Loosening: Can loosen over time in high-vibration environments.

- Limited Reusability: Usually a one-time use fastener; cannot be removed cleanly.

Solid Riveting Advantages

- High Strength: Creates a very strong, permanent joint suitable for load-bearing applications.

- Durability: Excellent for aerospace, automotive, and heavy machinery where joint strength matters.

- Resistant to Vibration: Less likely to loosen under stress or vibration.

Solid Riveting Disadvantages

- Requires Access to Both Sides: Must be installed from both sides, which can complicate assembly.

- More Skill Needed: Installation often requires more technique and specialized tools.

- Longer Installation Time: Slower process compared to blind riveting, impacting efficiency for large projects.

Both blind rivets and solid rivets have clear strengths and weaknesses. Your choice depends on the project’s needs, access, and load requirements. For detailed machining fasteners and assembly tips, check out our resources on cold riveting.

Choosing the Right Riveting Method for Your Project

Picking between blind riveting and solid riveting depends on a few key factors tied to your specific project needs. Here’s what you should keep in mind:

Factors to Consider

- Accessibility: If you only have access to one side of the materials, blind riveting (also known as pop riveting) is your go-to option. Solid riveting requires access to both sides for proper installation.

- Strength Requirements: For high-strength, load-bearing joints, solid rivets usually perform better because of their superior durability and structural integrity.

- Material Thickness and Type: Thin sheets and softer materials often suit blind rivets well, while thicker metals might need solid rivets for a stronger bond.

- Cost and Efficiency: Blind riveting tends to be faster and less labor-intensive, making it ideal for projects on tight schedules or with limited manpower.

- Environment and Durability: Consider exposure to vibration, weather, or heat. Solid rivets hold up better under harsh conditions, making them a top pick for aerospace and automotive applications.

Industry Specific Recommendations

- Automotive and Aerospace: Solid riveting is often preferred for structural components due to strength demands. However, blind rivets are used for secondary or less critical components where quick installation is vital.

- Sheet Metal Fabrication and CNC Machining: Blind rivets are common for assembling sheet metal parts due to ease of use and speed.

- Maintenance and Repairs: Blind riveting is excellent for quick fixes or repair work where disassembly might be needed later.

How HYCNC Can Help

At HYCNC, we understand the distinct requirements each industry and project brings. Our CNC machining services provide precision fasteners tailored to your riveting choice, whether it’s solid rivets or blind rivets. We also offer expert guidance to help you select the best mechanical fastening method to optimize strength, cost, and efficiency. Plus, our quick turnaround and quality control ensure your rivets meet tight deadlines without cutting corners.

For sheet metal projects, you might find our insights on designing sheet metal using SolidWorks helpful to ensure your rivet holes and layouts are spot on.

Choosing the right rivet type sets the foundation for a solid, lasting assembly. Let HYCNC help you get it right the first time.

Practical Tips for Effective Riveting

Hole Preparation

Proper hole preparation is crucial for a strong, reliable rivet joint. Make sure to:

- Use the right drill size to match the rivet diameter

- Deburr holes after drilling to prevent damage to the rivet or material

- Ensure holes are clean and free of dust, oil, or debris to improve grip and prevent corrosion

Tool Selection

Choosing the correct rivet installation tool makes all the difference:

- For blind riveting, use a quality pop rivet gun designed for the rivet size and material

- For solid riveting, use a rivet hammer or pneumatic rivet gun suitable for the rivet type

- Check that tools are well-maintained and calibrated for consistent performance

Quality Control

To ensure long-lasting rivet joints, keep these points in mind:

- Inspect each rivet for proper setting — the head should be flush and secure without cracks or deformation

- Test joint tightness and alignment after installation

- Use non-destructive testing methods if needed for critical applications like aerospace or automotive riveting

- Establish a routine inspection schedule to catch wear or loosening early

Following these tips will boost your success whether using blind rivets or solid rivets, helping you achieve secure, durable fastening every time. For more on riveting techniques and CNC machining fasteners, check out practical resources on sheet metal design and fabrication.

FAQs

What is the main difference between blind riveting and solid riveting?

Blind riveting uses a rivet that can be installed from one side, making it ideal when you can’t access both sides of the materials. Solid riveting requires access to both sides to hammer or press the rivet in place, providing stronger joints.

Can blind rivets hold as much weight as solid rivets?

Generally, solid rivets offer higher strength and durability because they create a more permanent bond. Blind rivets are strong enough for many applications but may not match the heavy-duty strength of solid rivets.

Where are blind rivets commonly used?

Blind rivets are widely used in automotive repairs, HVAC systems, and light sheet metal fabrication where quick installation and limited access are factors.

What industries rely on solid riveting?

Solid riveting is favored in aerospace, construction, and structural applications where strength and safety are top priorities.

Do I need special tools for blind riveting?

Yes, blind riveting usually requires a rivet gun or rivet installation tool, often lightweight and easy to use. Solid riveting needs a hammer or pneumatic rivet gun and sometimes specialized machinery.

Are blind rivets reusable?

No, both blind rivets and solid rivets are generally permanent fasteners and aren’t designed for reuse once installed.

How do I choose between blind riveting and solid riveting?

Consider your project’s strength requirements, access to both sides of the materials, and installation speed. Blind riveting works best for quick fixes and limited access; solid riveting is better for permanent, heavy-duty needs.

Can CNC machining services help with rivet installation?

Absolutely. CNC machines can precisely drill holes for rivets or even produce custom rivets and fittings for your project, ensuring a perfect fit and high-quality fastening.

If you need more guidance on choosing or installing blind rivets or solid rivets, feel free to reach out!