Introduction to 3-Axis CNC Machining

3-axis CNC machining is a precise computer numerical control (CNC) process that moves tools along the X, Y, and Z axes for accurate cutting and shaping. It’s ideal for producing 2D and 2.5D geometries, making it perfect for components that don’t require complex multi-axis movement.

At HYCNC, we combine industry-leading expertise with advanced machinery and a firm commitment to quality. Our 3-axis CNC services serve diverse industries including aerospace, automotive, and medical, ensuring your custom CNC parts meet the highest standards every time.

Why choose us? Precision, affordability, and fast turnaround for your custom parts.

-

Precision CNC machining guaranteed -

Custom CNC parts tailored to your needs -

Cost-effective CNC machining solutions -

Reliable CNC prototyping services -

Expertise in aerospace and automotive CNC parts -

Serving customers searching for “CNC machining near me”

Applications of 3-Axis CNC Machining

Our 3-axis CNC machining services deliver precision and reliability across key industries. We specialize in aerospace components like brackets, panels, and structural parts, ensuring strict compliance with ISO certifications and industry standards. For the automotive sector, we produce engine parts, mounts, and custom fittings crafted with the finest accuracy. We also support medical device manufacturing by machining surgical tools and device components with exacting standards.

Industries Served

- Aerospace brackets, panels & structural components

- Automotive engine parts, mounts & custom fittings

- Medical surgical tools & device components

Typical Parts Produced

- Flat plates, housings, and molds

- Prototypes and small-batch production

- Custom CNC parts to exact specifications

Our Expertise

- Meeting ISO and industry-specific certifications

- Cost-effective 3-axis CNC machining for metals

- Custom solutions for aerospace and automotive parts

Explore more about our precise CNC machining services or discover why aerospace CNC machining demands precision like no other.

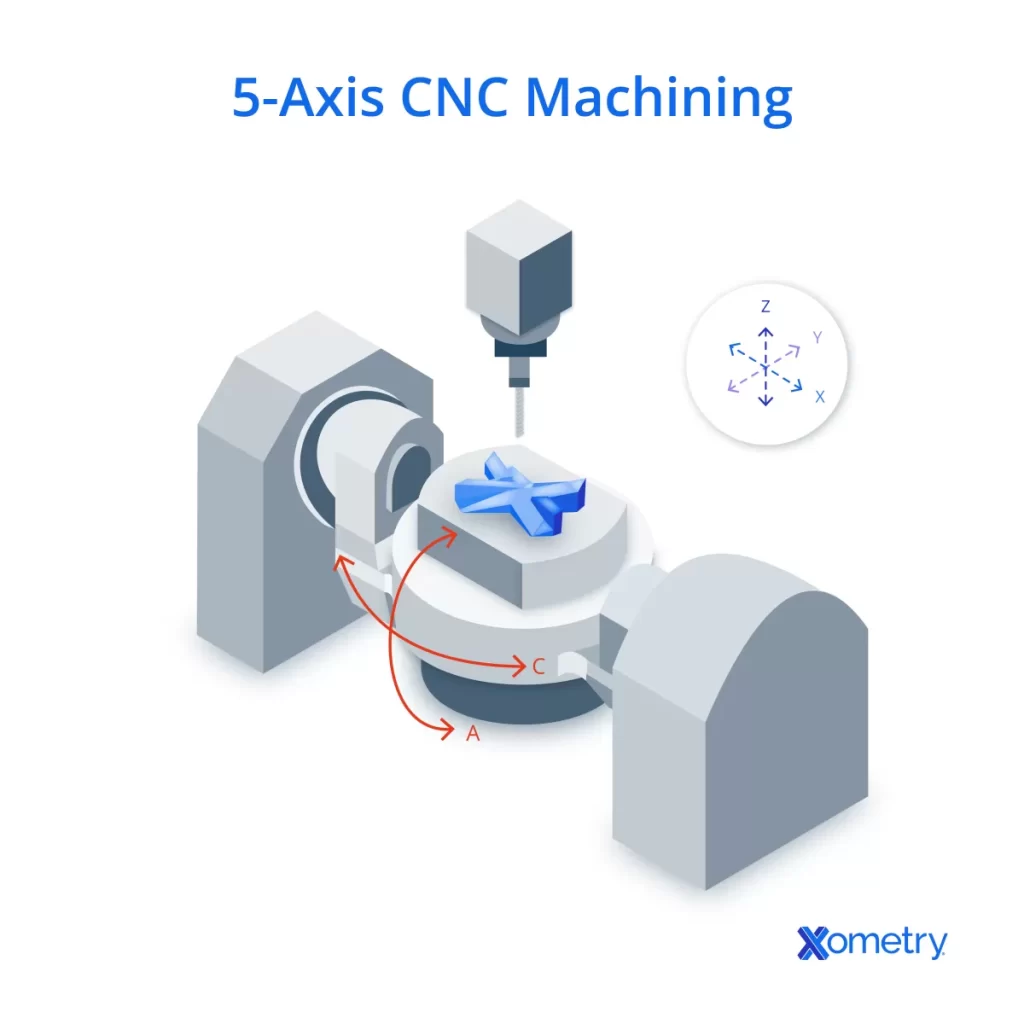

3-Axis vs 5-Axis CNC Machining: Which Is Right for You?

Understanding the key differences helps you choose the best CNC machining service for your project needs.

3-Axis CNC Machining

-

Operates on X, Y, and Z axes (three directions) -

Ideal for simpler parts and flat geometries -

Faster turnaround – great for cost-effective CNC machining

5-Axis CNC Machining

-

Adds two extra rotational axes for greater flexibility -

Best for complex geometries and intricate aerospace or automotive CNC parts -

Higher cost due to setup and machine complexity

When speed, cost, and simplicity are priorities, 3-axis CNC machining is often your best choice. Need help? At HYCNC, we offer free consultations to match the perfect 3-axis CNC services to your custom CNC parts and prototyping goals.

Why Choose HYCNC for 3-Axis CNC Machining

High-performance CNC machines delivering precision CNC machining and unmatched efficiency.

Engineers and machinists with decades of expertise in creating custom CNC parts and complex components.

Fast delivery tailored for the US market and worldwide clients needing reliable aerospace CNC machining & more.

From CNC prototyping to large-scale production — flexible to meet every project’s unique demands.

Rigorous inspections and strict adherence to machining tolerances guarantee top-quality results every time.

How HYCNC’s 3 Axis CNC Machining Process Works

We make precision CNC machining simple and clear. Here’s our step-by-step guide to turning your custom CNC parts into reality — with flexibility and support every step of the way.

Get Started with 3 Axis CNC Machining Today

Request a quote or reach out to our team to explore cost-effective, precision CNC machining solutions near you.

Competitive Pricing

Enjoy affordable CNC parts with fast lead times and no compromise on quality.

Proudly Local

Serving your local area with reliable 3-axis CNC services tailored to your needs.

Easy Contact

Use our online form, call or email to get fast replies for your CNC prototyping and custom parts.

FAQs About 3-Axis CNC Machining

What materials can HYCNC machine with 3-axis CNC?

At HYCNC, our 3-axis CNC machining expertly handles a wide range of metals including aluminum, steel, stainless steel, brass, copper, and titanium. We also work with select plastics suited for precision CNC prototyping and custom CNC parts, ensuring versatility for aerospace CNC machining and automotive CNC parts alike.

How does 3-axis CNC compare in cost to other methods?

3-axis CNC machining is one of the most cost-effective CNC machining methods, especially for simpler geometries and moderate production volumes. Compared to 5-axis CNC, it reduces equipment and programming costs, making it ideal for tight budgets without sacrificing precision and quality. Learn more about when to choose 3-axis vs 5-axis CNC machining.

What are the lead times for HYCNC’s 3-axis machining services?

We pride ourselves on quick turnaround times without compromising quality. Typical lead times range from a few days to two weeks depending on project complexity and volume. We are fully equipped to meet urgent demands and scale capacity for custom CNC parts or CNC prototyping work.

Can HYCNC handle large-scale production runs?

Absolutely. Our 3-axis CNC services are designed to support both small batch prototypes and high-volume production. We use robust CNC machining for metals and maintain strict precision machining standards to ensure consistency throughout every run.