Understanding ABS Acetone Smoothing

What Is ABS Acetone Smoothing

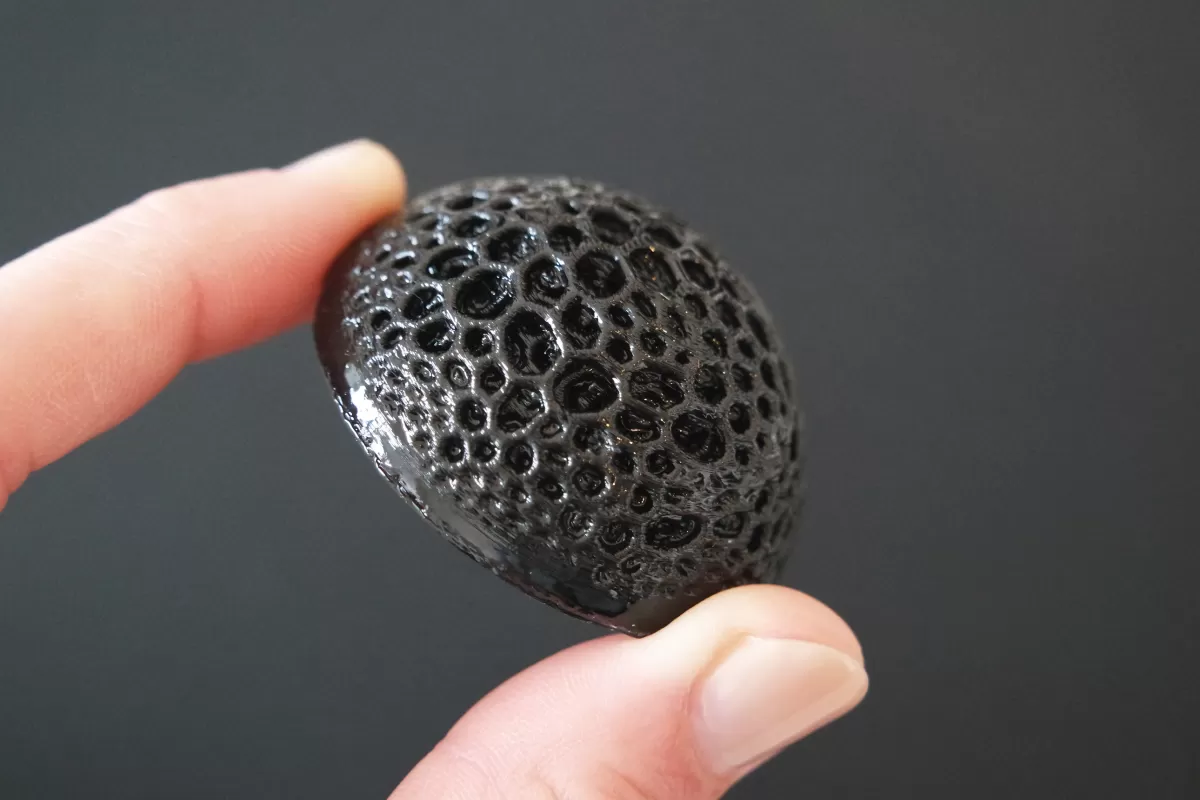

If you’ve ever noticed the rough layer lines on your ABS 3D prints, ABS acetone smoothing is a popular way to fix that. This process uses acetone, a common solvent, to slightly melt the outer surface of an ABS print. As the acetone evaporates, it smooths out those visible ridges, leaving your part with a glossy, professional-looking finish. It’s a simple but effective post-processing technique that enhances the visual quality and feel of your ABS prints.

Why Choose ABS for 3D Printing

ABS is a favorite among 3D printing enthusiasts and professionals because it’s sturdy, heat-resistant, and easy to post-process. Unlike other materials, ABS responds well to acetone vapor smoothing, which makes finishing smoother and faster. Its strength and durability also mean that smoothed parts can be used for functional prototypes, tools, or end-use applications without sacrificing performance.

Applications of Smoothed ABS Parts

Smoothed ABS parts aren’t just for looks—they have lots of real-world uses. You’ll find them in:

- Functional Prototypes where surface finish matters

- Consumer Products like phone cases or custom enclosures

- Automotive Parts requiring tough, heat-resistant surfaces

- Cosmetic Enhancements for parts used in robotics or gadgets

Smoothing ABS helps reduce friction on moving parts, improve paint adhesion, and increase overall durability. It’s a favorite finishing step in both home setups and professional 3D printing services for achieving that sleek, polished appearance.

Methods of ABS Acetone Smoothing

When it comes to ABS acetone smoothing, there are several methods you can use depending on your setup and the finish you want.

Acetone Vapor Smoothing

This is the most popular method. You expose your ABS print to acetone fumes in a closed container. The vapor gently melts the surface layer, reducing visible layer lines and giving a glossy finish. It’s great for smoothing complex shapes without losing detail.

Brush-On Acetone Smoothing

If you want more control, you can apply acetone directly with a brush. This works well for small areas or touch-ups but requires a steady hand. It’s quicker but less even than vapor smoothing.

Acetone Bath Smoothing

For a fully immersed approach, some dip their ABS parts in acetone briefly. This melts the surface quickly, but it’s riskier since too much exposure can warp or deform your print. Use with caution.

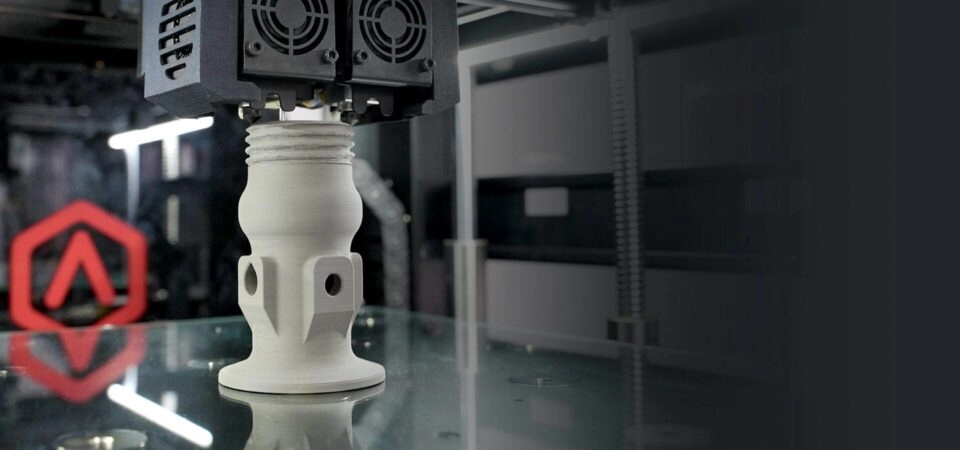

Professional Smoothing Equipment

For consistent and safe results, professional acetone smoothing machines are available. They control acetone exposure carefully and are a good choice for businesses or serious hobbyists looking for high-quality finishes without the guesswork.

Each method has its pros and cons, so choose the one that fits your project scope and safety comfort level.

Safety Precautions for ABS Acetone Smoothing

Why Safety Matters

When working with acetone for ABS acetone smoothing, safety isn’t optional. Acetone is a strong solvent that can cause health issues if inhaled or handled improperly. It’s highly flammable, so ignoring safety can quickly lead to accidents or injury. Protecting yourself ensures smooth results and a safe workspace.

Essential Safety Tips

- Work in a well-ventilated area to avoid inhaling harmful fumes. Outdoors or rooms with strong airflow are best.

- Wear protective gloves to keep acetone off your skin. It can cause irritation or dryness.

- Use safety goggles to shield your eyes from splashes or vapor.

- open flames or sparks since acetone vapors are extremely flammable.

- Store acetone properly in a cool, sealed container away from heat sources.

- Have a fire extinguisher nearby just in case.

- Use respiratory protection like masks if you’re exposed to acetone vapor for an extended time.

Common Mistakes to Avoid

- Don’t skip ventilation. The fumes can build up fast and cause dizziness or headaches.

- Never apply acetone directly from the bottle; always use controlled methods like vapor smoothing or a brush.

- Don’t leave acetone soaking too long—it can weaken your ABS part or distort details.

- Avoid mixing acetone with other chemicals without guidance; reactions can be unpredictable.

- Don’t dispose of acetone improperly; follow local hazardous waste rules.

By following these safety steps, you’ll keep your 3D printing post-processing on track without risking injury or damage.

Tips for Achieving the Best Results

Getting a smooth, glossy finish with ABS acetone smoothing takes some practice, but these tips can help you nail it every time.

Choose High-Quality ABS Filament

Start with good ABS filament. Cheap or inconsistent filament can lead to uneven surfaces and poor smoothing results. Look for reliable brands that offer consistent diameter and color, so your print layers bond well and respond better to acetone vapor smoothing.

Optimize Exposure Time

The key to a perfect finish is the right amount of acetone exposure. Too little won’t smooth out the layer lines; too much can warp or over-soften your print. I recommend starting with short exposure sessions (2–5 minutes) and inspecting your print often. Adjust exposure based on your print size and layer thickness for the best balance of smoothness and detail.

Post-Smoothing Care

After acetone smoothing, let your print dry fully in a well-ventilated area. Avoid touching the surface until it hardens again to preserve that shiny, professional look. If needed, you can lightly sand rough spots after drying or apply a clear coat for extra protection and shine.

When to Outsource to Professionals

If you’re working on a big project or want a flawless finish without the hassle, professional 3D printing services or CNC prototyping shops can do ABS acetone smoothing for you. They use controlled equipment to ensure consistent results and follow strict acetone safety precautions, saving you time and risk.

By following these tips, your ABS 3D printing post-processing will look cleaner, smoother, and more polished — just the way you want it.

Alternatives to Acetone Smoothing

If you’re looking for other ways to smooth your 3D printed ABS parts or working with different filaments, there are a few alternatives to acetone smoothing that work well.

Sanding and Polishing

A classic method is to sand your print gradually using fine-grit sandpaper, then polish it to get a smooth surface. This takes more time and effort but gives you great control over the finish without using any chemicals. It’s perfect if you want to avoid acetone altogether or work in a space with limited ventilation.

Liquid Coatings

Applying liquid coatings like epoxy resin or clear acrylic spray can also smooth out layer lines and add a glossy finish. These coatings create a protective layer that enhances durability and appearance. They’re especially useful for parts that will face wear or outdoor conditions.

Other Solvents for Non-ABS Filaments

Not all filaments respond to acetone. For example, PLA prints can be smoothed using solvents like ethyl acetate or specialized PLA smoothing solutions. These alternatives help soften the surface without damaging the print, but always check solvent compatibility with your filament type and use proper safety gear.

Choosing the right smoothing method depends on your filament, workspace, and the final look you want. Each approach has its strengths, so pick what suits your project best.

FAQs

What is ABS acetone smoothing used for

ABS acetone smoothing is a popular way to smooth out rough surfaces and visible layer lines on 3D printed ABS parts, giving them a glossy, finished look.

Is acetone smoothing safe for ABS 3D prints

Yes, when done with proper safety precautions. Acetone is flammable and gives off strong fumes, so work in a well-ventilated area and avoid open flames.

How long does acetone vapor smoothing take

Typically, vapor smoothing takes anywhere from 10 to 30 minutes depending on the size of the part and the desired smoothness.

Can I use acetone on other filaments besides ABS

No, acetone works best with ABS filament. Other filaments like PLA or PETG don’t respond well and may get damaged.

What’s the difference between vapor smoothing and brush-on acetone smoothing

Vapor smoothing uses acetone fumes to evenly smooth the entire part’s surface, while brush-on smoothing involves applying acetone liquid directly with a brush for spot treatment.

How do I avoid over-smoothing or warping my ABS part

Control exposure time carefully, use clean acetone, and avoid soaking the print. Practice on test prints before working on important parts.

Can I use professional 3D printing services for acetone smoothing

Yes, many professional services offer acetone smoothing to get perfect, glossy finishes without the hassle or safety concerns of DIY methods.

Are there alternatives to acetone smoothing for ABS prints

Yes, sanding and polishing, liquid coatings, or CNC machining can also improve surface finish if you want to avoid acetone use.

Got more questions about ABS acetone smoothing or 3D printing post-processing? Feel free to reach out for more tips!