The Zinc Die Casting Process Explained

If you’ve ever wondered how precision metal parts are made quickly and efficiently, zinc die casting is a major player. This process involves injecting molten zinc alloy into a steel mold—or die—under high pressure to create detailed, durable components.

Step by Step Breakdown

Here’s how zinc die casting typically works:

- Melting the zinc alloy: Zinc, often as zamak alloys, is melted at a controlled temperature.

- Injecting molten metal: The hot liquid metal is forced into a precision-machined steel die using high pressure.

- Cooling and solidifying: The metal cools rapidly inside the die, instantly forming the desired shape.

- Ejecting the part: Once solidified, the die opens, and the part is ejected for finishing.

- Trimming and finishing: Excess metal is removed, and parts get any additional surface treatment needed.

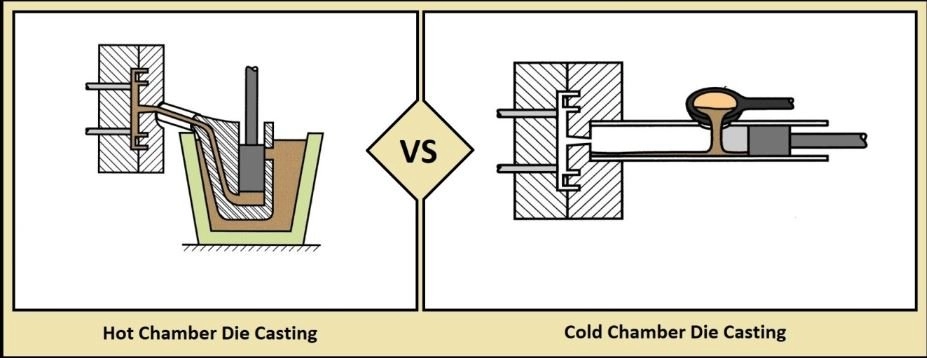

Hot Chamber vs Cold Chamber Die Casting

Zinc die casting primarily uses the hot chamber method, which is ideal because zinc melts at a relatively low temperature (~787°F or 419°C). In this process, the injection mechanism is submerged in molten zinc, allowing for faster cycles and less metal loss.

By contrast, cold chamber die casting is used for metals with higher melting points like aluminum or magnesium but is less common for zinc.

Why hot chamber is better for zinc die casting:

- Faster production speeds due to quicker injection

- Less wear on equipment since zinc alloy melts at low temperature

- More cost-effective for high-volume runs

Knowing these basics helps you understand how zinc alloy die casting delivers high precision parts efficiently. In upcoming sections, we’ll break down the key benefits and where this process shines most.

Key Benefits of Zinc Die Casting

Zinc die casting offers several advantages that make it a top choice for manufacturers across the U.S. Here’s why it stands out:

-

High Precision and Complex Geometries

Zinc alloy die casting allows for tight tolerances and intricate designs. This means you get parts with fine details and thin walls, perfect for applications where accuracy matters.

-

Cost Efficiency

The die casting process is fast and produces minimal waste. Plus, zinc melts at a lower temperature than aluminum or magnesium, reducing energy costs and speeding up production.

-

Strength and Durability

Despite being lightweight, zinc is strong and impact-resistant. It’s great for parts that need to hold up under stress, like automotive components or electronics housings.

-

Superior Surface Finish

Zinc casting delivers smooth, clean surfaces right out of the mold, cutting down on extra finishing work and saving time.

-

Eco Friendly

Zinc is 100% recyclable and uses less energy in production compared to other metals. This makes zinc die casting a greener choice for companies aiming to reduce their environmental impact.

-

Versatility

Whether you need consumer goods, medical devices, or telecommunications parts, zinc die casting adapts to a wide range of industries and product requirements.

These benefits combined make zinc die casting a smart, reliable choice for precision manufacturing in today’s fast-paced market.

Applications of Zinc Die Casting

Zinc die casting is widely used across many industries in the U.S. because of its strength, precision, and cost efficiency. Here are some key areas where zinc alloy die casting shines:

Automotive Industry

Zinc components are found in many automotive parts, like brackets, housings, and connectors. The ability to create thin wall casting with high precision makes zinc ideal for durable, lightweight car parts that meet strict quality standards.

Electronics

Zinc die casting is perfect for electronics housings that require excellent dimensional accuracy and a smooth surface finish. It protects sensitive parts while keeping production costs low, making it popular in everything from computers to home appliances.

Consumer Goods

From hardware to sporting equipment, zinc cast parts offer durability and a great look. Its versatility allows for complex shapes and designs that improve both function and style in everyday products.

Medical and Telecommunications

In medical devices and telecom equipment, precision manufacturing is critical. Zinc die casting delivers reliable components that meet high safety and performance standards, often used in connectors, housings, and structural parts.

Zinc die casting’s combination of strength, detail, and cost-effectiveness makes it a go-to choice in these industries and beyond.

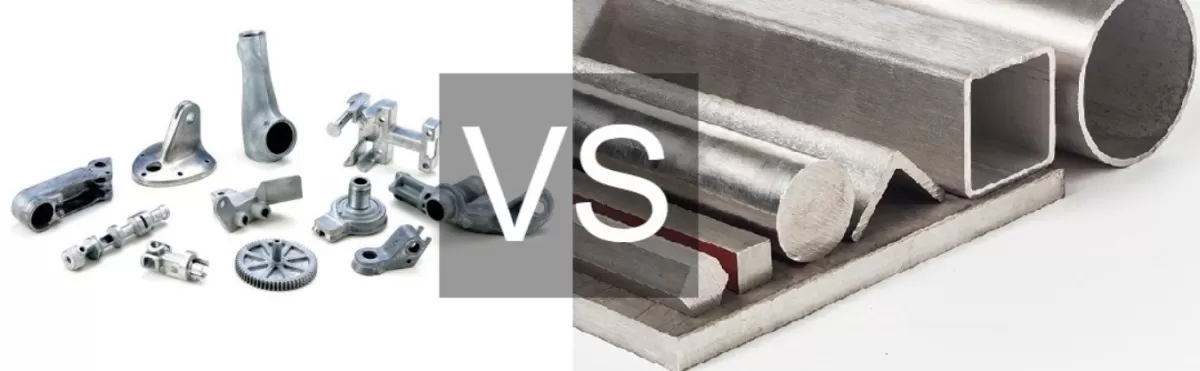

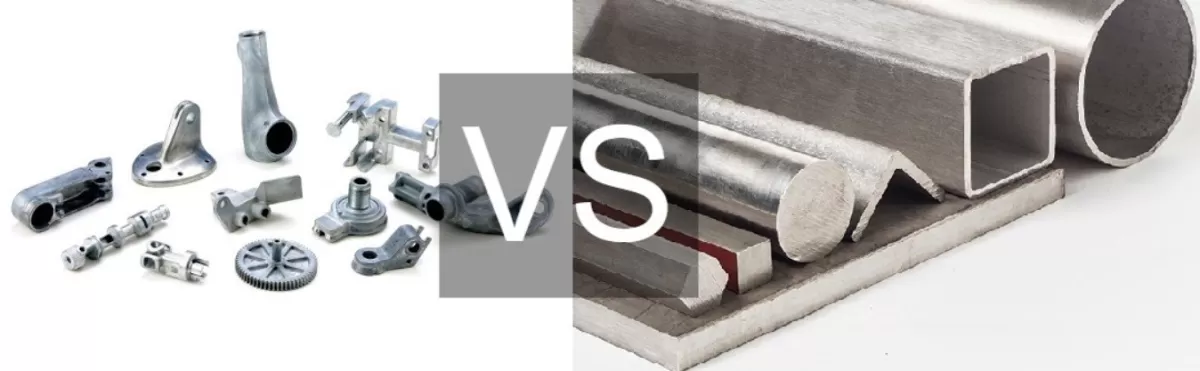

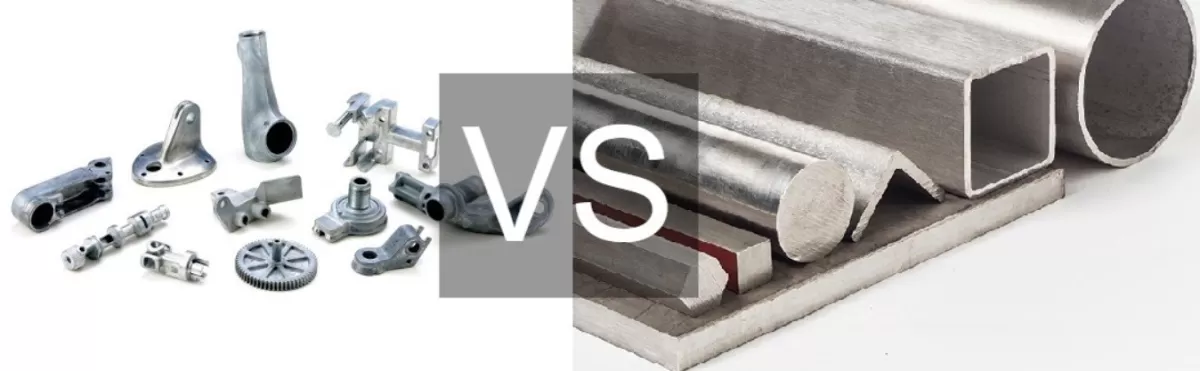

Zinc Die Casting vs Other Materials

When choosing the right material for your project, understanding how zinc stacks up against others like aluminum, magnesium, and plastics is key.

Zinc vs Aluminum

- Strength and Durability: Zinc alloys offer better strength and wear resistance than aluminum, making them ideal for parts needing more toughness.

- Precision: Zinc’s lower melting point allows for thinner walls and more detailed shapes with high precision.

- Cost Efficiency: Zinc is generally more cost-effective in high volume runs due to faster cycle times and less machining needed.

Zinc vs Magnesium

- Weight: Magnesium is lighter, which is a plus for applications where reducing weight matters (like aerospace).

- Strength: Zinc has higher strength and better corrosion resistance than magnesium, so it lasts longer in tough environments.

- Ease of Casting: Zinc’s hot chamber die casting process is faster and less expensive than magnesium’s cold chamber method.

Zinc vs Plastics

- Durability: Zinc parts are stronger, more heat resistant, and less prone to warping compared to plastic components.

- Surface Finish: Zinc offers a smoother, more attractive finish straight from the mold, reducing post-production work.

- Environmental Impact: Zinc alloys are recyclable and more eco-friendly than many plastics, aligning well with sustainability goals.

Choosing zinc die casting means balancing strength, precision, and cost — often delivering better value for a wide range of manufacturing needs here in the U.S.

Why Choose HYCNC for Zinc Die Casting

When it comes to zinc die casting, HYCNC stands out for several reasons tailored to the needs of U.S. customers.

Expertise in Precision Manufacturing

We specialize in precision manufacturing, using advanced CNC machining and high-pressure casting techniques. This means your parts meet tight tolerances and complex designs without compromise.

Custom Solutions

Every project is different. We offer custom zinc alloy die casting solutions—from thin wall casting to zamak alloys—so you get exactly what fits your application, whether it’s automotive components or electronics housings.

Commitment to Quality

Quality is our priority. We follow strict quality control standards to ensure durability and a superior surface finish on every piece. This reduces waste and keeps your budget in check.

Sustainability Focus

HYCNC is committed to eco-friendly casting. Zinc die casting at our facility focuses on reducing energy use and recycling scraps, supporting your sustainability goals without sacrificing performance.

Choosing HYCNC means getting reliable, cost-effective casting paired with expert service right here in the U.S.

Limitations of Zinc Die Casting

While zinc die casting offers many advantages, it’s important to know its drawbacks before deciding if it’s the right choice for your project.

Weight Considerations

Zinc alloys are heavier than materials like magnesium or some plastics. If your application requires extremely lightweight parts, zinc might not be the best fit.

High Initial Tooling Costs

The die casting process needs precise molds, which can be expensive upfront. This means zinc die casting is more cost-effective for medium to large production runs rather than small batches.

Temperature Limitations

Zinc melts at a lower temperature compared to aluminum or magnesium. While this makes it easier to cast, it also means zinc parts may not perform well in high-heat environments or applications requiring extreme thermal resistance.

Understanding these limitations helps ensure you get the best results when choosing zinc alloy die casting for your parts.

Future Trends in Zinc Die Casting

The zinc die casting industry is evolving fast with new tech and market demands shaping what’s next. Here are some trends you can expect to see:

Simulation Software

Advanced simulation tools are helping manufacturers predict how molten zinc alloys flow in the die casting process. This means fewer defects, faster turnaround, and optimized designs. Using simulation software cuts down trial and error, saving time and money while improving precision manufacturing.

Sustainability

With more focus on eco-friendly production, zinc die casting is becoming greener. Zinc alloys like zamak are fully recyclable, and manufacturers are adopting cleaner processes to reduce waste and energy use. Sustainability matters in the US market, so expect zinc casting companies to push even harder on reducing their carbon footprint.

New Applications

Zinc die casting keeps expanding beyond traditional sectors like automotive and electronics. Its versatility makes it a top choice for newer industries such as medical devices, telecom gear, and even lightweight smart home products. Thin wall casting and high-pressure casting advancements allow complex, durable, and cost-effective parts to be made for cutting-edge uses.

Staying ahead with these trends means getting better quality, more sustainable, and innovative zinc alloy die casting solutions for a wide range of needs.