What is Hot Chamber Die Casting

Hot chamber die casting is a manufacturing process used to create precise metal parts by injecting molten metal into a steel mold under high pressure. This method is especially suited for metals with low melting points, like zinc, magnesium, and certain alloys.

Here’s how it works step-by-step:

- The metal is melted in a heated holding furnace that’s connected directly to the casting machine.

- A device called a gooseneck arm dips into the molten metal and pulls it into a chamber.

- Then, under high pressure, the molten metal is forced into the mold cavity.

- Once cooled and solidified, the mold opens and the finished part is ejected.

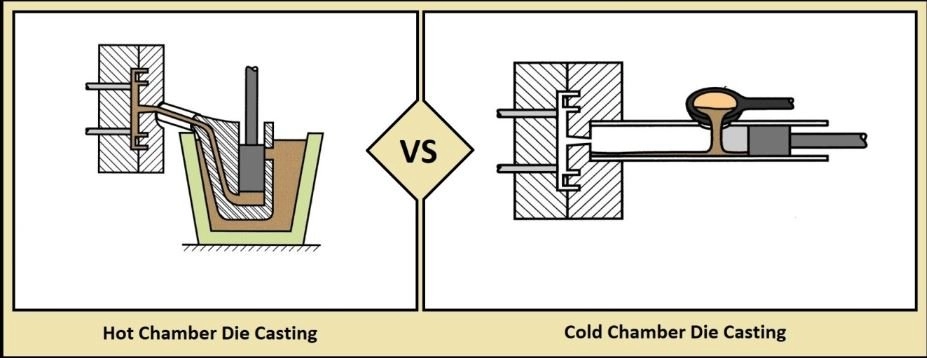

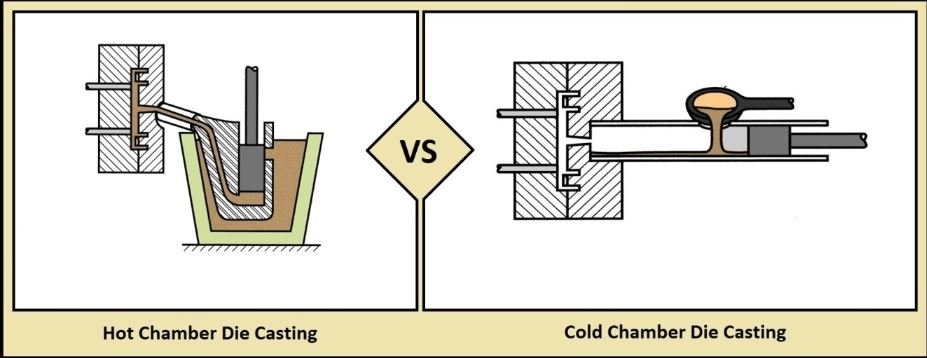

Compared to cold chamber die casting, hot chamber offers faster cycle times because the molten metal is always ready inside the machine. Cold chamber requires manually pouring molten metal into the injection chamber for each shot, making it slower and better suited for metals with higher melting points like aluminum.

In , hot chamber die casting is ideal for producing high volumes of small, detailed metal parts quickly and efficiently when working with low melting point alloys.

Materials Used in Hot Chamber Die Casting

Hot chamber die casting works best with low-melting-point metals because the process involves a gooseneck mechanism that sits inside a molten metal bath. This setup requires metals that won’t damage the machine or solidify too quickly. Common alloys used include:

- Zinc alloys: Popular for their strength, corrosion resistance, and excellent surface finish.

- Magnesium alloys: Known for being super lightweight and offering good mechanical properties.

- Tin alloys: Less common but useful for specialty parts needing wear resistance.

- Lead and other low melting point metals: Used for specific industrial applications.

These low melting point alloys reduce wear on the die and machine parts, leading to longer equipment life and less downtime. Plus, they allow for faster cycle times and greater precision in the final product. Zinc and magnesium alloys especially stand out because they provide a great balance of durability, weight savings, and cost-effectiveness — perfect for automotive die casting and electronics parts where quality and lightweight matter.

Advantages of Hot Chamber Die Casting

Hot chamber die casting offers several clear benefits that make it a popular choice for many manufacturers, especially in the U.S. market.

-

Fast Cycle Times

The hot chamber process is known for quick production cycles. Since the metal is melted inside the machine’s gooseneck, it can be injected rapidly into the die. This speeds up manufacturing and helps meet tight deadlines without compromising quality.

-

High Precision and Surface Finish

This method delivers highly detailed, smooth parts right out of the mold. You get consistent precision with minimal post-processing, which is ideal for parts like automotive components and electronics where fit and finish matter.

-

Cost-Effectiveness and Waste Reduction

Because the metal is reused inside the machine, scrap is lower compared to other casting methods. It’s efficient with material use, which saves money, especially when working with zinc die casting or magnesium die casting alloys.

-

Long Die Life

The lower temperatures involved in hot chamber die casting put less stress on the molds. This extends die life and reduces downtime and maintenance costs, making the process even more economical for high-volume production.

For a deeper dive into our die casting process options, check out our die casting services page.

Limitations of Hot Chamber Die Casting

Hot chamber die casting is great, but it does have some limits you should consider:

-

Limited to Low-Melting-Point Metals

This process mainly works with metals like zinc, magnesium, and some aluminum alloys. Metals with higher melting points, such as steel or copper, can’t be used because the machine parts could get damaged.

-

Potential Porosity Issues

Sometimes, trapped gases or shrinkage can cause tiny holes (porosity) in the cast parts. These can affect the strength and surface finish, so additional inspection or post-processing might be necessary.

-

Best Suited for Smaller Parts

Hot chamber die casting shines with smaller, intricate components due to its quick cycles and precision. However, it’s not the best choice for large or very thick parts, which usually require cold chamber die casting instead.

-

Project Suitability Considerations

If your project needs parts made from high-melting alloys or involves bulkier pieces, hot chamber die casting may not be cost-effective or practical. Knowing the size, metal type, and detail level helps decide if this method fits your needs.

For more insights on different casting processes, check our guide on what is die casting.

Applications of Hot Chamber Die Casting

Hot chamber die casting is widely used across various industries because it delivers fast, precise production of small to medium-sized parts. Here are some key applications where this process really shines:

Automotive Components

Many automotive parts like fuel system components, carburetors, and small brackets are made using hot chamber die casting. The process handles zinc die casting and magnesium die casting well, producing durable parts with great surface finishes.

Electronics Enclosures and Connectors

Because of its precision and ability to handle low melting point alloys, hot chamber die casting is ideal for making electronic housings, connectors, and cases. These parts need to be lightweight, strong, and have tight tolerances—perfect for this method.

Consumer Goods

From kitchen gadgets to hardware tools, hot chamber die casting creates metal parts that are both affordable and reliable. It’s popular for producing intricate shapes that require fine details and smooth surfaces.

Aerospace Lightweight Parts

In aerospace, keeping components light without sacrificing strength is key. Hot chamber die casting helps by producing lightweight metal parts, often using magnesium alloys, that meet strict quality standards.

Industry-Specific Solutions

Other specialized sectors like telecommunications, medical devices, and industrial machinery also benefit from hot chamber die casting for custom metal parts that require precision and repeatability.

These applications show why hot chamber die casting is a go-to process for precision metal parts, especially when speed and cost-efficiency matter.

Why Choose HYCNC for Hot Chamber Die Casting

When it comes to hot chamber die casting, HYCNC stands out with state-of-the-art machines designed for fast, precise production runs. Our advanced equipment handles high-pressure die casting with consistent quality, making sure your parts meet even the strictest standards.

We offer comprehensive services, including expert die design and top-notch CNC machining. This means you get a full package—from the initial design to the final finished part—under one roof, saving you time and hassle.

Quality control is at the heart of what we do. Our team uses precision engineering techniques and rigorous testing to ensure every batch is flawless, reducing waste and keeping your costs down.

Plus, HYCNC specializes in custom solutions tailored to your project. We’ve worked across many industries and can share proven case studies to help guide your next project toward success.

Choose HYCNC for reliable, high-quality hot chamber die casting that fits your needs and deadlines perfectly.

How to Get Started with HYCNC

Getting started with HYCNC for your hot chamber die casting needs is simple and straightforward. Here’s how we make the process easy and smooth for you:

-

Consultation Process

We begin with a detailed consultation to understand your project requirements, material preferences, and design goals. This helps us recommend the best die casting solutions tailored to your needs.

-

Requesting Quotes

After assessing your specs, we provide a clear, competitive quote with transparent pricing. No hidden costs—just straightforward info to help you plan your budget.

-

Design Collaboration and Prototyping

Work hand in hand with our engineers for design tweaks and prototyping. We use advanced CNC machining services to make sure your parts are precise and ready for production.

-

Contact and Call-to-Action

Ready to start? Reach out to us today through our website or give us a call. Our team is here to guide you from concept to finished part with expert advice and quick turnaround.

You can learn more about our full range of die casting services here or explore our metal casting capabilities here. Let’s bring your project to life with quality and precision.

FAQs about Hot Chamber Die Casting

What metals are used in hot chamber die casting?

Hot chamber die casting works best with low melting point alloys like zinc, magnesium, and certain aluminum alloys. These metals melt easily and flow well, making them ideal for the hot chamber process.

How does hot chamber die casting differ from cold chamber?

The main difference: hot chamber keeps the metal molten inside the machine, making it faster and better for low melting point metals. Cold chamber injects metal from an external furnace, which suits higher melting point metals like aluminum and copper.

Which industries benefit most from hot chamber die casting?

Industries like automotive, electronics, consumer goods, and aerospace rely on this process for precision metal parts that need fast production and good surface finish.

Why is hot chamber die casting cost-effective?

It offers quick cycle times, less metal waste, longer die life, and high precision—reducing overall production costs significantly.

How does HYCNC support hot chamber die casting projects?

HYCNC provides full services: from die design and prototyping to CNC machining and quality control. They work closely with you to deliver custom, precision parts that fit your project needs.