What is Die Casting Understanding the Basics

Die casting is a metal casting process where molten metal is forced into a mold under high pressure. This technique allows the creation of precise, complex parts with excellent surface finish and tight tolerances. Originally developed in the 19th century for making printing presses, die casting has evolved into a vital manufacturing method used across automotive, aerospace, and electronics industries.

Why does die casting matter? It supports high-volume production of durable, lightweight components while minimizing material waste. This combination of speed, precision, and efficiency makes die casting an essential choice for modern manufacturing needs.

At HYCNC, we combine our CNC processing expertise with advanced die casting capabilities. This integration helps us deliver high-quality, precision metal parts tailored to your specifications, ensuring both reliability and scalability for your projects. Learn more about our die casting services here.

How Does Die Casting Work The Process Explained

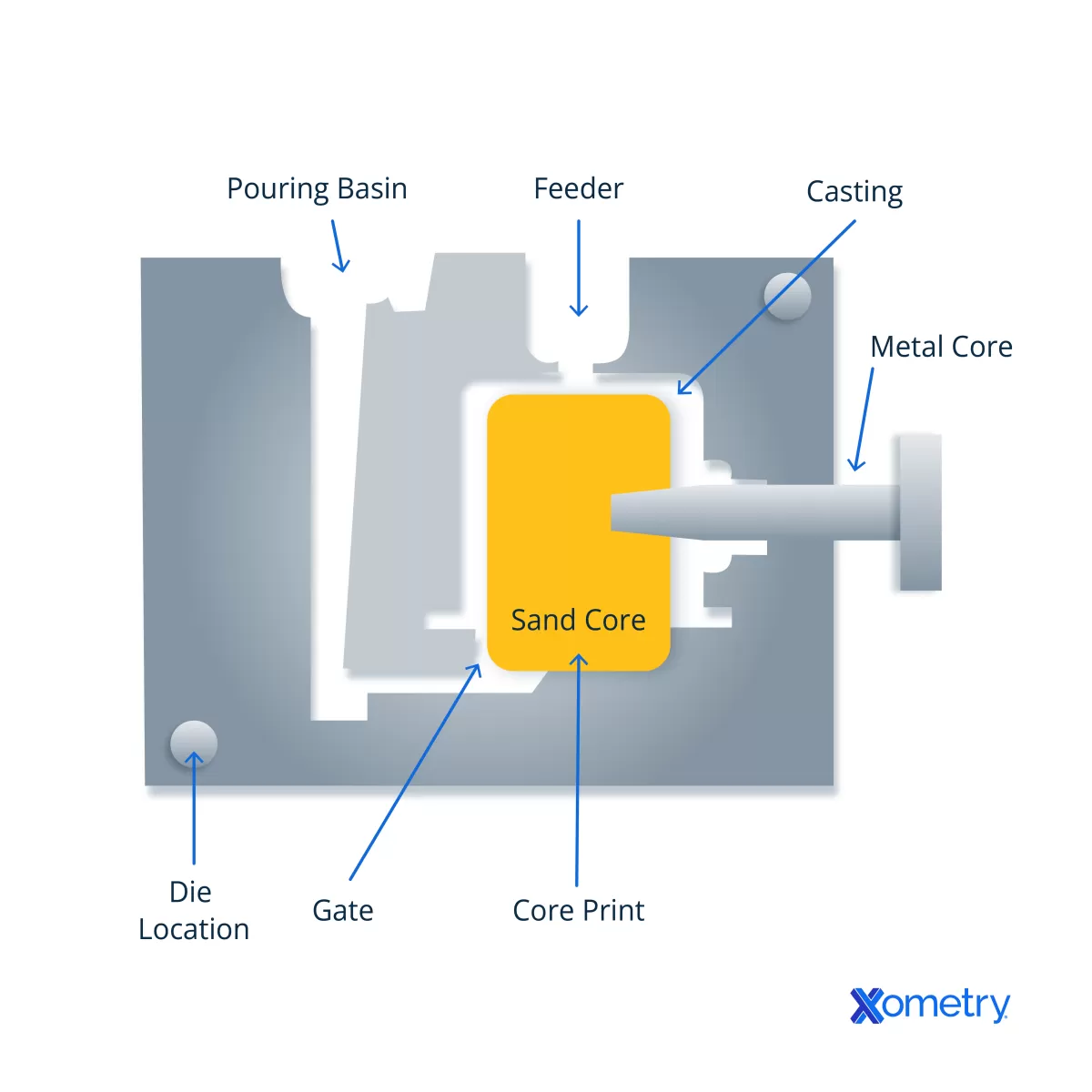

Die casting is a straightforward but precise process. Here’s a quick step-by-step rundown of how it works:

-

Mold Preparation and Clamping

First, a reusable steel mold (called a die) is cleaned and tightly clamped shut to handle high pressure.

-

Melting Non-Ferrous Metals

Metals like aluminum, zinc, and magnesium are melted down in a furnace. These non-ferrous metals are popular because they’re lightweight and corrosion-resistant.

-

High-Pressure Injection

The molten metal is then forced into the die at high pressure using a die casting machine. This pressure fills every part of the mold quickly, capturing fine details and complex shapes.

-

Cooling and Solidification

Once inside the mold, the metal cools down and solidifies into the part’s shape.

-

Part Ejection

After solidifying, the die opens, and ejector pins push the finished part out. The mold then closes again, ready for the next cycle.

Key components in this process include the furnace (to melt metal), the die casting machine (which injects metal under pressure), and the reusable molds themselves. These molds allow fast, accurate, and repeatable production runs.

Visual Aid Suggestion

Including a simple diagram can help you see each step visually—from melting and injection to cooling and ejection—making the process easier to understand.

Types of Die Casting

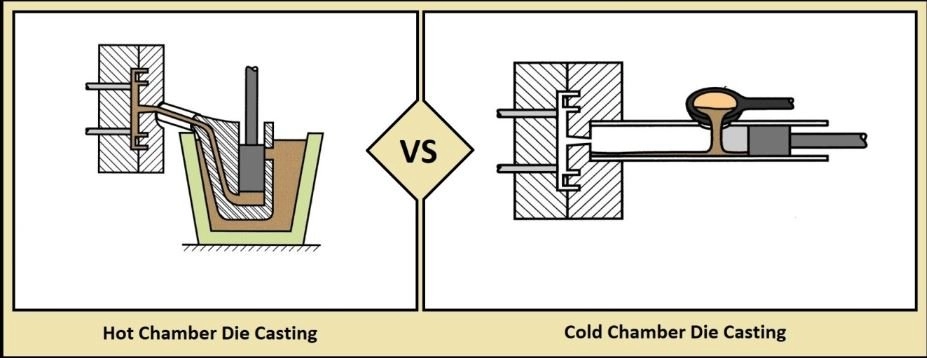

There are two main types of die casting, each suited for different metals and needs.

Hot Chamber Die Casting

- Best for low-melting-point metals like zinc and magnesium

- The furnace is built right into the machine, which means faster cycle times and efficient production

- Commonly used for smaller parts that need quick turnaround

Cold Chamber Die Casting

- Designed for higher-melting-point metals such as aluminum and copper

- The metal is melted in an external furnace and then injected into the die, making it ideal for corrosion-resistant and durable parts

- Often chosen when working with alloys that require higher temperatures

Besides these, there are other variants like vacuum die casting and squeeze casting. These advanced methods help improve strength and reduce defects, especially for critical applications.

At HYCNC, we’re equipped to handle both hot chamber and cold chamber die casting processes. This flexibility allows us to recommend the best casting method depending on your material needs and project requirements.

Materials Used in Die Casting

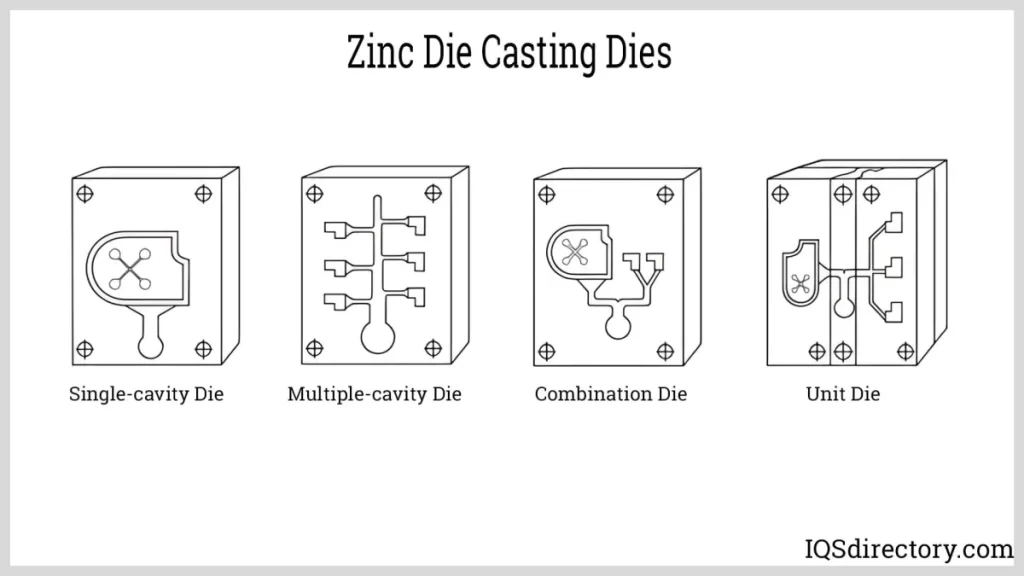

Die casting mainly uses non-ferrous metals, which are perfect for lightweight, durable parts. The most common choices are:

- Aluminum: Lightweight, corrosion-resistant, and great for automotive parts.

- Zinc: Offers high precision and is ideal for intricate designs.

- Magnesium: The lightest option, used when weight savings are key.

Alloys like Zamak 5 (a type of zinc alloy), AZ91D (a popular magnesium alloy), and various aluminum alloys are popular in industries like automotive and electronics.

When choosing materials, you want to balance:

- Strength

- Weight

- Cost-effectiveness

At HYCNC, we specialize in recommending the best material for your project based on these factors, ensuring you get a strong, affordable part that fits your exact needs.

Applications of Die Casting Across Industries

Die casting is everywhere, powering key parts in many industries thanks to its precision and strength.

- Automotive: From engine blocks and transmission housings to battery casings for electric vehicles, die casting helps create lightweight, durable components that stand up to tough conditions.

- Aerospace: It delivers lightweight parts for aircraft engines and landing gear, reducing weight without compromising safety or performance.

- Electronics: Die casting is perfect for making housings for smartphones, cameras, and connectors where precision and fine detail matter.

- Medical: The process produces highly accurate components for medical devices like pacemakers and surgical tools, where reliability is critical.

At HYCNC, we understand these demands well. With our expertise in CNC machining combined with die casting, we deliver quality parts tailored for automotive, aerospace, electronics, and medical sectors. Check out our die casting services to see how we support your industry needs.

Advantages of Die Casting

Die casting offers several big benefits that make it a go-to choice for many industries:

- High precision and tight tolerances: Die casting can achieve tight tolerances, usually between IT10 and IT15, so parts fit together perfectly with minimal adjustments.

- Excellent surface finish: Parts come out smooth and clean, which cuts down on finishing work like sanding or machining.

- Cost-effective for high-volume production: Once the mold is made, die casting allows fast, repeatable production with very little material waste, lowering overall costs.

- Durability and strength: Die-cast parts are strong, reliable, and great for products that need to withstand wear and tear.

- Sustainability: The process uses recyclable metals and is designed to reduce waste, supporting eco-friendly manufacturing practices.

These advantages explain why aluminum die casting, zinc die casting, and magnesium die casting are popular in automotive, aerospace, and electronics manufacturing. At HYCNC, we combine die casting with precise CNC machining to deliver quality parts that meet high standards and tight deadlines.

For more on our die casting and metal casting capabilities, check out our die casting services page.

Challenges and Limitations of Die Casting

Die casting comes with a few challenges you should know about. First, the initial tooling cost for molds is pretty high. Building these precise molds takes time and money upfront, which can be a barrier for small production runs.

Also, die casting mainly works with non-ferrous metals like aluminum, zinc, and magnesium. It’s not suitable for steel or other ferrous metals because of their higher melting points and different properties.

Another common issue is defects like porosity—tiny air pockets that can weaken parts. These defects can be minimized through techniques like vacuum die casting and strict quality control measures.

At HYCNC, we tackle these challenges head-on. Our expertise in mold design and rigorous quality checks helps reduce defects and improve part consistency. We focus on making sure your parts meet tight tolerances while keeping costs manageable—so you get reliable, high-quality die cast components every time.

Die Casting vs Other Casting Methods

When comparing die casting to other casting methods, there are a few things to keep in mind:

- Sand Casting is better for low-volume production and larger parts due to its flexibility and lower initial costs. However, it lacks the precision and surface finish of die casting.

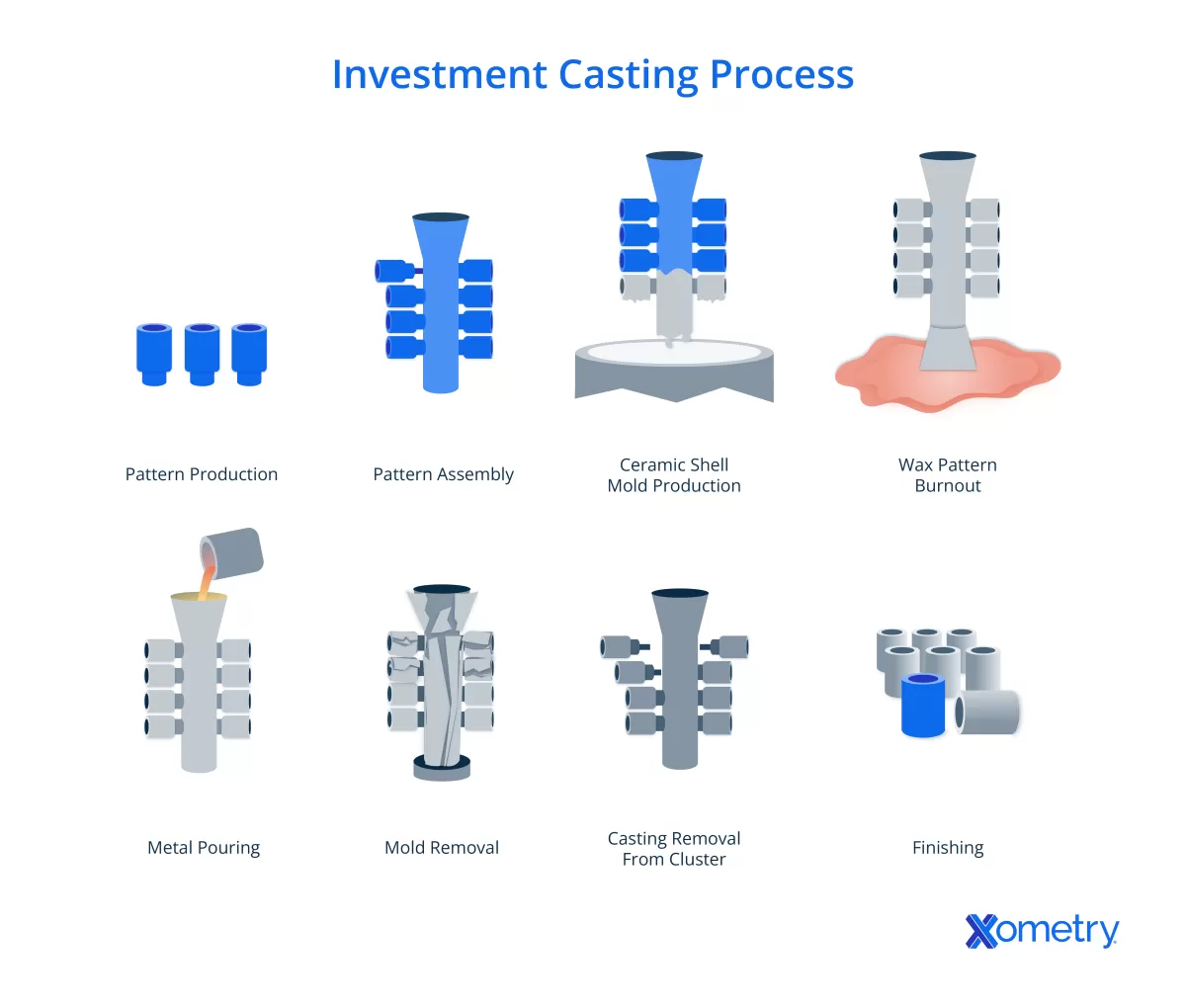

- Investment Casting offers very high precision and excellent detail, but it’s slower and more expensive, making it less ideal for large-scale runs.

Die casting stands out because of its speed, tight tolerances, and ability to produce complex parts consistently at scale. It delivers high-quality parts faster and with less post-processing than other methods, which is perfect for industries that demand precision and volume.

At HYCNC, we bring an edge by combining die casting with advanced CNC machining. This integration means parts not only have great surface finish and accuracy straight from the mold but can also be finely tuned with CNC processes. It’s a winning combo for clients needing complex, high-precision components delivered on time.

Learn more about how our die casting services complement our CNC machining capabilities to provide end-to-end manufacturing solutions.

Trends and Innovations in Die Casting

Die casting is always evolving, especially with the growing demand for lightweight and precision parts. One big trend is using lighter materials like aluminum, which is popular in electric vehicles such as Tesla’s Cybertruck. Aluminum helps cut weight and boost efficiency, which is crucial for EV performance.

Automation and smart technology are also changing the game. AI and robotics improve accuracy and speed in the die casting process, reducing errors and raising overall quality. These advancements make it easier to meet tight tolerances and deliver consistent parts.

Sustainability is becoming a top priority too. Recycling metals and adopting energy-efficient processes help reduce waste and lower environmental impact. This shift aligns with the push for greener manufacturing in the U.S. market.

At HYCNC, we stay ahead by integrating these innovations into our die casting services. Our use of advanced technologies ensures precise, durable parts with a focus on efficiency and sustainability to meet today’s standards.

How to Choose a Die Casting Service Provider

Picking the right die casting service provider is key to getting quality parts on time and within budget. Here are some important factors to consider:

- Experience and Expertise: Look for a provider with a proven track record in die casting, especially with materials like aluminum, zinc, and magnesium. Experience means fewer surprises and better results.

- Material Knowledge: The provider should understand different alloys and help you choose the best material based on your project’s strength, weight, and cost needs.

- Quality Control: Precision matters. Make sure they have strong quality control processes to catch defects like porosity early and deliver parts that meet tight tolerances.

- Scalability: Whether you need a small batch or high-volume production, your provider should be able to scale smoothly without compromising quality.

- Design for Manufacturability (DFM): A service that offers DFM support can save you time and money by optimizing your design for die casting before production starts.

At HYCNC, we combine comprehensive CNC machining and die casting services to give you the best of both worlds. We offer fast quotes, expert material advice, and reliable quality assurance to keep your project on track. For more on our die casting capabilities, check out our die casting services and related metal casting techniques.