What is Deburring and Why Does It Matter

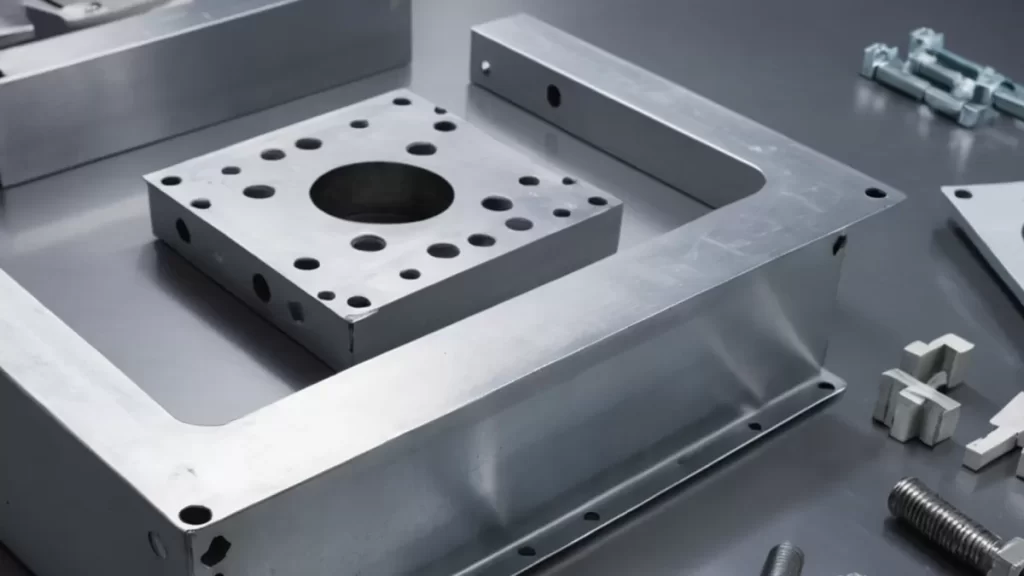

Deburring is the process of removing sharp edges, burrs, and unwanted material left on a part after machining. In CNC machining, deburring plays a crucial role in ensuring parts are safe to handle, fit precisely, and function reliably. Burrs can cause assembly problems, wear down other components, or create safety hazards. That’s why effective deburring is essential to maintain quality and performance in manufactured parts.

Many industries rely heavily on deburring, including:

- Aerospace – where precision and safety are critical for every component

- Automotive – to ensure smooth, reliable operation of engines and systems

- Medical Devices – for parts that require exact tolerances and biocompatibility

- Electronics – where tiny burrs can interfere with assembly or performance

- Metal Fabrication – to improve surface finish and prepare parts for coating or painting

At HYCNC, we understand that deburring is not just a finishing step—it’s a vital part of delivering quality CNC machined parts that exceed customer expectations.

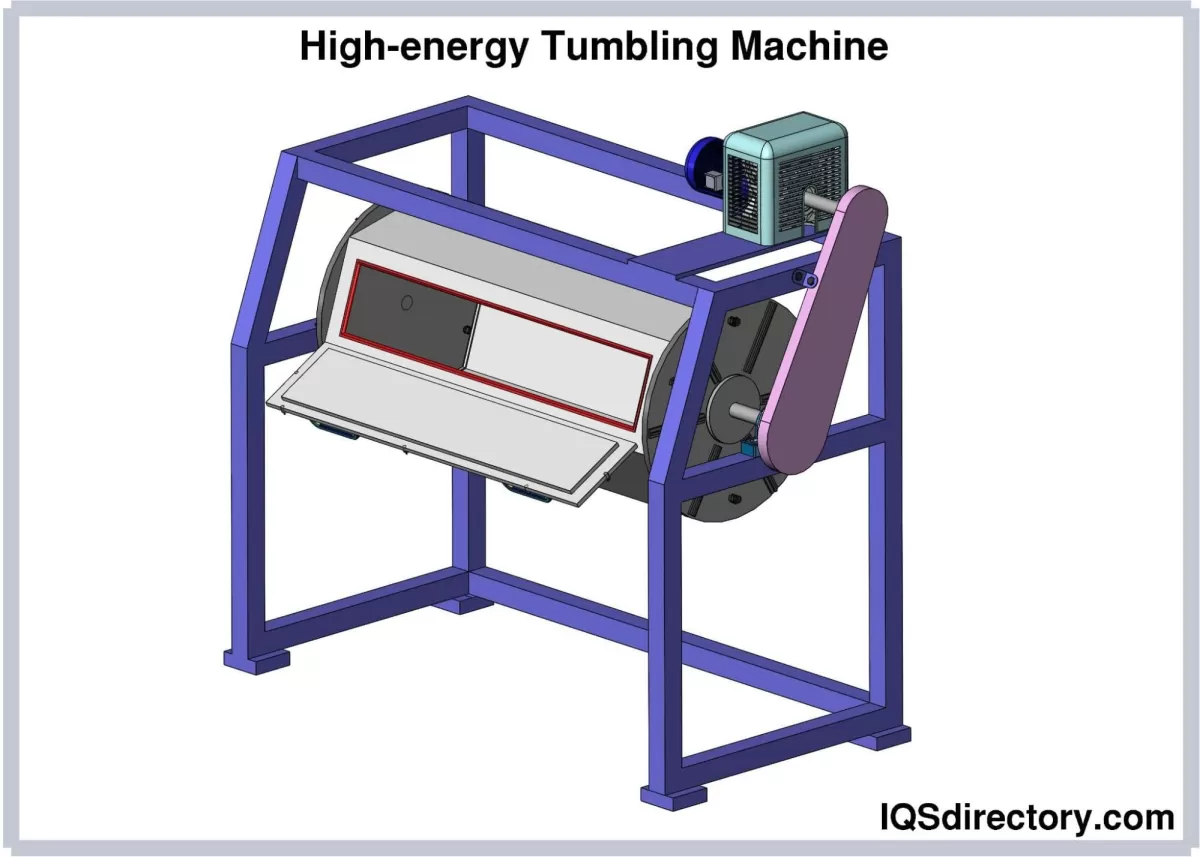

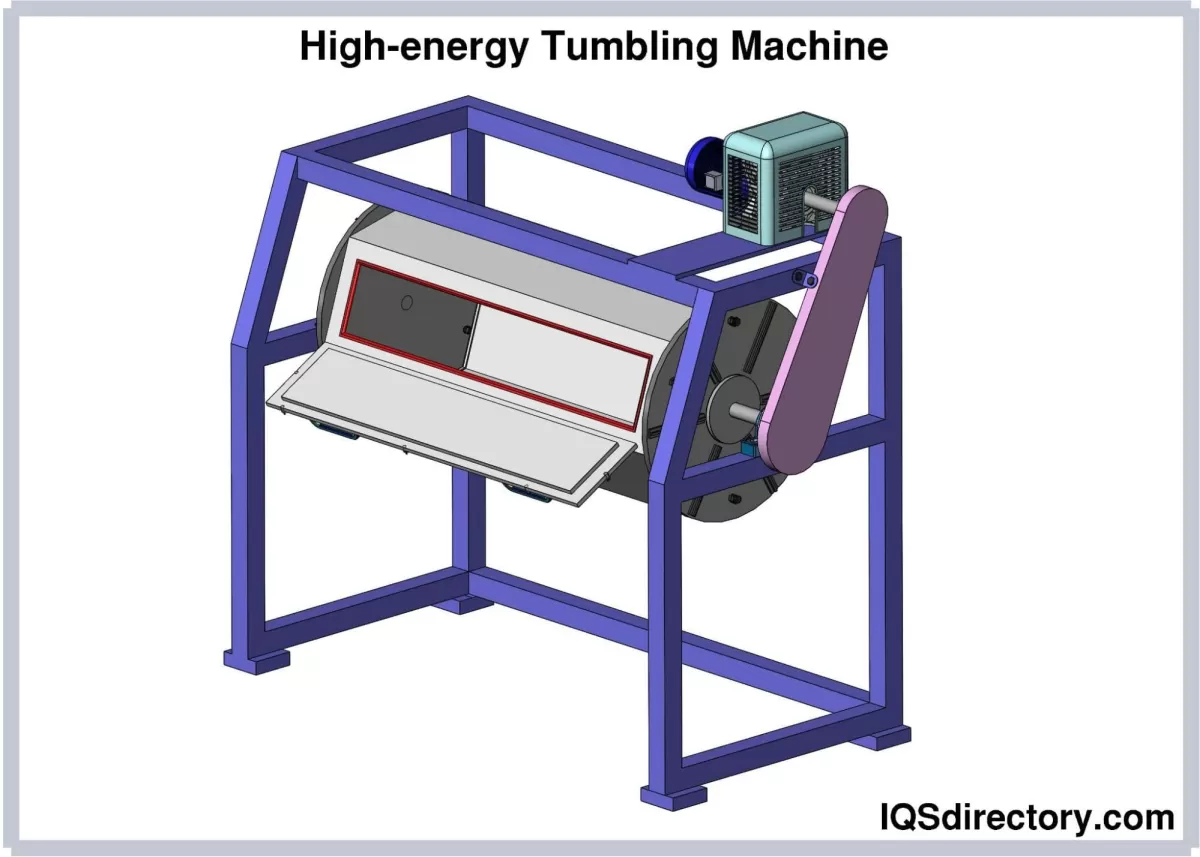

Tumbling Deburring Process and Key Features

Tumbling deburring works by placing a batch of parts into a rotating drum or vibratory machine along with abrasive media. As the drum rotates or vibrates, the media rubs against the part surfaces, gently removing burrs, sharp edges, and excess material. This process is widely used for smoothing and polishing, making it ideal for large batches of small to medium-sized parts.

Types of Abrasive Media Used

- Ceramic media: Durable and great for heavy deburring and surface finishing

- Plastic media: Softer, used for light deburring and polishing

- Steel media: Effective for tough materials like stainless steel

- Organic media: Biodegradable options for eco-friendly finishing

Key Features of Tumbling Deburring

- Handles multiple parts in one cycle, boosting batch productivity

- Works well on complex geometries as media reaches cavities and edges

- Can provide both deburring and surface smoothing in the same step

- Suitable for a range of materials including metals, plastics, and alloys

Advantages of Tumbling Deburring

- Efficient for high-volume deburring and surface finishing

- Reduces manual labor with bulk processing

- Offers consistent finish quality across all parts

- Versatile with many types of tumbling media available

Limitations of Tumbling Deburring

- Not ideal for very large or delicate parts that can be damaged in the process

- Can sometimes round sharp edges beyond desired specifications

- Cycle times can be longer compared to linear methods for small batches

- Less control on precise areas needing deburring compared to linear methods

Tumbling deburring is a proven metal finishing technique for batches where uniform finishing is key, but it needs careful media selection and process control to get the best results.

Linear Deburring Process and Key Features

Linear deburring uses sanding belts or brushes that move in a straight line to remove burrs from parts. The workpiece passes through or is held against the moving abrasive surface, smoothing edges and cleaning up rough spots. This process is common for parts with simple shapes or where precision along flat or straight edges is needed.

How Linear Deburring Works

- Parts contact a moving sanding belt or brush that runs in a linear path

- The abrasive media scrapes or buffs away burrs along edges or surfaces

- Pressure and speed can be adjusted depending on the material and burr size

- Often used in automated setups for consistent results on each piece

Key Features of Linear Deburring

- Suitable for parts with flat surfaces and straight edges

- Uses belts, brushes, or abrasive pads moving linearly

- Adjustable speed and pressure for different materials

- Can be integrated with CNC machines or standalone units

- Ideal for precision edge finishing

Advantages of Linear Deburring

- Delivers consistent, repeatable finishes

- Good for medium to high-volume production

- Precise control over deburring location and intensity

- Less aggressive than tumbling, preserving part details

- Easier to handle irregular burrs on edges and flat surfaces

Limitations of Linear Deburring

- Not ideal for complex 3D shapes or small parts with hard-to-reach burrs

- Limited effectiveness on internal burrs or very detailed features

- Can require more manual setup for varied part sizes or geometries

- May need multiple passes for heavy burrs, increasing cycle time

Linear deburring is a solid choice for straightforward, precision edge deburring in industries that require reliability and consistent surface finishing.

Tumbling vs Linear Deburring Side by Side Comparison

Part Size and Geometry

Tumbling deburring works best with small to medium parts, especially batches where parts can move freely inside a barrel or vibratory tumbler. It handles complex shapes well because the abrasive media reaches hard-to-access edges. On the flip side, linear deburring is great for larger, flat, or simple-shaped parts since it uses sanding belts or brushes moving along a fixed path. If your parts are long or consistent in shape, linear deburring offers better control.

Material Compatibility

Tumbling suits a wide range of metals and some plastics, but softer materials can get damaged if the abrasive media is too harsh. Linear deburring handles sensitive materials better because the force and pressure can be finely tuned. Materials prone to deformation or requiring precise finishing often benefit from linear methods.

Finish Quality

Tumbling delivers a uniform finish over the entire surface, smoothing out rough edges and burrs in batch processes. However, it might not achieve the same level of precision on delicate features compared to linear deburring. Linear deburring offers more precise, consistent edge finishing, especially on straight or simple profiles, making it ideal for parts needing tight tolerances.

Cost and Efficiency

Tumbling is cost-effective for large batches since multiple parts are processed simultaneously, reducing labor and cycle time per piece. Its upfront setup is simple with low operator involvement. Linear deburring often requires more operator time or complex automation, which can raise costs but provides better accuracy for smaller runs or specialized parts.

Automation and Labor Considerations

Tumbling is highly automated with minimal labor needed once the machine is loaded, great for high-volume production. Linear deburring can be automated but often needs careful setup and monitoring, especially when dealing with varied or complex parts. Labor input is generally higher, but the tradeoff is better control and finish consistency.

In short, choosing between tumbling vs linear deburring depends on your part size, material, finish needs, budget, and production volume. At HYCNC, we help you pick the right method to fit your project and get the best results.

When to Choose Tumbling Deburring with HYCNC

Tumbling deburring is a great choice when you need to process a large batch of small to medium-sized parts with complex shapes. It works well for parts that can tolerate some movement during finishing and need consistent edge smoothing or surface polishing. Industries like automotive, aerospace, and electronics often rely on tumbling to quickly remove burrs from metal, plastic, or mixed-material components.

At HYCNC, we optimize tumbling deburring by carefully selecting the right tumbling media and process parameters based on your part’s size, material, and geometry. Our expertise ensures that parts come out with smooth, uniform finishes while minimizing wear or damage. Plus, our automated tumbling setups handle big volumes efficiently, reducing labor time and keeping costs down. If you’re looking for reliable, consistent batch deburring, tumbling with HYCNC is a smart, cost-effective option.

When to Choose Linear Deburring with HYCNC

Linear deburring is a great fit for parts that need precise edge removal and consistent surface finishing, especially when working with long, straight edges or flat surfaces. If your project involves delicate materials or parts with sensitive features that require controlled abrasion, linear deburring with sanding belts or brushes is often the best choice.

Here are some ideal scenarios for choosing linear deburring with HYCNC:

- Parts with uniform edges, like metal sheets or plates

- Components requiring a smooth finish without altering the part’s shape

- Jobs needing fast changeover between different polishing or deburring steps

- Materials sensitive to aggressive tumbling media, like thin aluminum or stainless steel

- Small to medium-sized production runs where consistent repeatability is key

At HYCNC, we focus on precision linear deburring by using advanced CNC-controlled sanding belts and brush systems. This lets us tightly control pressure and speed, delivering even surface finish and sharp edge definition every time. Our process is designed to minimize part distortion and ensure durable, high-quality results that meet your exact specifications.

With our expertise in CNC machining and finishing, HYCNC tailors the linear deburring process to your unique needs—helping you achieve top-notch surface quality without extra hassle.

Choosing the Right Tumbling Media for Your Project

Picking the right tumbling media is key to getting the best finish and keeping your parts safe throughout the CNC deburring process. Tumbling media comes in several types, each designed for different materials and finishes.

Overview of Tumbling Media Types

- Ceramic media: Great for heavy-duty deburring and smoothing hard metals. It’s durable and cuts quickly.

- Plastic media: Softer and less aggressive, perfect for delicate parts that need a gentler touch.

- Steel media: Often used for heavy cleaning and burnishing, especially on tougher metals.

- Natural media: Like walnut shells or corn cob, used mainly for polishing and light cleaning.

Factors to Consider in Media Selection

- Material compatibility: Make sure the media won’t damage or react with the part’s metal.

- Part geometry: Complex shapes might need softer media to avoid missing tight spots or causing deformation.

- Desired finish: Rough tumbling media is best for fast deburring, while finer media works for polishing and smoothing.

- Batch size: Larger batches may benefit from more aggressive media to save time.

HYCNC’s Custom Media Selection Approach

At HYCNC, we don’t do one-size-fits-all. We evaluate your specific part material, shape, and finish needs to tailor the tumbling media mix. This custom approach ensures efficient deburring without compromising quality. Plus, we adjust media blends to optimize cycle times and surface finish based on your project goals, giving you the best bang for your buck.

How HYCNC Can Help You Decide

At HYCNC, we bring deep expertise in CNC machining and deburring, making it easier for you to choose the right process for your project. Whether you need tumbling deburring for batch parts or precise linear deburring for complex geometries, our team knows the ins and outs of each method.

We start with a thorough consultation to understand your part design, material, finish requirements, and budget. From there, we recommend a tailored deburring solution that balances quality, speed, and cost-efficiency. Our custom approach includes selecting the best tumbling media or linear finishing techniques to get the job done right.

Ready to improve your surface finishing and save time? Contact HYCNC today for a free consultation and let us help you find the perfect CNC deburring process for your next job. Reach us at [phone number] or visit our website to get started.