Are you looking to master the sheet metal fabrication process but unsure where to start? Choosing the right materials and understanding key applications can transform your project’s success, whether you’re building car parts or aerospace components.

As a manufacturing expert, I’ve seen how the right fabrication approach saves time, cuts costs, and delivers precision. This guide, backed by real-world insights, breaks down the sheet metal fabrication process, explores top materials like steel and aluminum, and highlights diverse applications across industries.

At HYCNC, we’ve perfected CNC sheet metal fabrication to deliver flawless results. Ready to dive into the ultimate resource for creating high-quality metal components? Let’s get started!

What Is Sheet Metal Fabrication

Sheet metal fabrication is the process of cutting, shaping, and assembling thin metal sheets into finished products or components. It plays a crucial role in various industries by transforming flat metal pieces into complex parts used in everything from cars and airplanes to electronics and construction materials.

Precision matters a lot in sheet metal fabrication. Even small errors can lead to parts that don’t fit properly or fail under stress. With high precision, manufacturers can ensure consistency, reduce material waste, and improve the overall quality of the metal components. This is especially important in applications like aerospace or medical equipment, where tight tolerances and exact specifications are critical.

In short, sheet metal fabrication combines skilled craftsmanship with advanced technology to create reliable, durable metal parts for countless uses.

Key Sheet Metal Fabrication Processes

Sheet metal fabrication involves several core processes that transform raw metal sheets into precise, functional parts. Here’s a quick look at the main steps:

Cutting

This is the first and crucial step. Common cutting techniques include:

- Laser cutting: Uses focused light to create clean, precise cuts, ideal for complex shapes.

- CNC turret punch press: Efficient for punching repetitive holes or patterns.

- Waterjet cutting: Uses high-pressure water mixed with abrasive material for cutting without heat distortion.

Learn more about cutting options in our guide on the best way to cut sheet metal.

Bending

After cutting, sheet metal is bent into shape using machines called press brakes. This process needs precision to create accurate angles and curves without damaging the material. For a deeper dive, check out our page on metal bending.

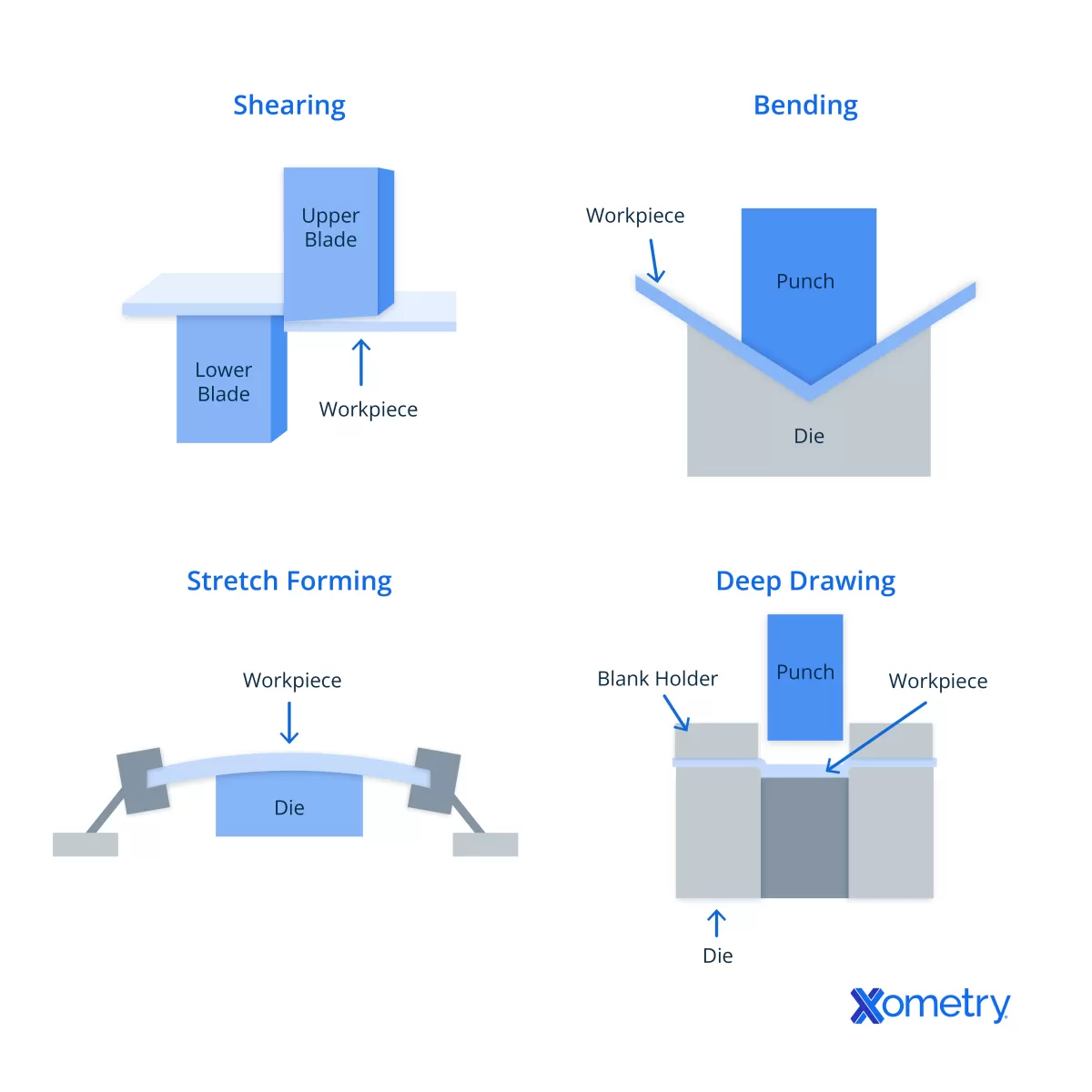

Forming and Shaping

These methods help shape the metal beyond basic bends:

- Rolling: Bends sheets into cylinders or curves.

- Stamping: Presses designs or shapes into metal using dies.

- Progressive die molding: Combines multiple forming steps in a single press cycle for faster production.

Joining and Assembling

Once formed, pieces are joined by:

- Welding: Fusing metals together for strong, permanent bonds.

- Riveting: Mechanical fastening for durability when welding isn’t ideal.

- Fastening: Using screws, bolts, or adhesives as needed.

Finishing

The final appearance and protection come from surface treatments like:

- Powder coating: Adds a durable, colorful finish.

- Anodizing: Increases corrosion resistance, especially on aluminum parts.

CNC Technology Integration

Modern sheet metal fabrication heavily relies on CNC (computer numerical control) technology. CNC machines control cutting, bending, and forming with unmatched precision and repeatability, improving quality and reducing waste. This integration is key for meeting today’s demanding manufacturing standards.

Common Materials in Sheet Metal Fabrication

When it comes to sheet metal fabrication, choosing the right material is key. Here’s a quick look at the most common metals and what makes them stand out:

-

Steel

Steel is strong, affordable, and versatile. It’s widely used in construction, automotive parts, and heavy machinery. Its durability and easy weldability make it a top choice for many industrial metal fabrication projects.

-

Stainless Steel

Known for its corrosion resistance and sleek finish, stainless steel is popular for applications requiring hygiene and rust-proof qualities. You’ll often see it in food processing, medical equipment, and outdoor structures.

-

Aluminum

Aluminum is lightweight and corrosion-resistant, which makes it ideal for aerospace, automotive, and electronics cases. It’s easy to shape and bends well, perfect for complex designs in the CNC metal fabrication world.

-

Titanium

Titanium stands out in aerospace and high-performance industries due to its exceptional strength-to-weight ratio and corrosion resistance. It’s more expensive but offers long-term durability where weight savings are critical.

-

Other Materials

Copper, brass, and nickel alloys also have their place. Copper is great for electrical applications thanks to its conductivity. Brass offers good machinability and looks great in decorative features. Nickel alloys shine in high-temperature environments.

How We Choose the Right Material

Material selection depends on balancing:

- Strength needs

- Weight considerations

- Corrosion resistance

- Cost constraints

Thanks to CNC precision, we expertly handle all these materials, delivering consistent, high-quality custom metal components tailored to your specific project needs.

Applications of Sheet Metal Fabrication

Sheet metal fabrication plays a key role across several industries in the U.S., thanks to its versatility and precision. Here’s where you’ll commonly find it:

-

Automotive: Used for making body panels, exhaust systems, chassis parts, and brackets. The strength and flexibility of sheet metal help meet safety and design needs.

-

Aerospace: Crucial for manufacturing wings, fuselages, and structural supports. Materials like aluminum and titanium are shaped with precision to meet strict standards.

-

Construction: Structural components, roofing, and HVAC systems rely on durable sheet metal parts that resist weather and provide long-term support.

-

Electronics: Enclosures and heat sinks are crafted to protect devices and manage heat efficiently, using materials like aluminum and copper.

-

Medical Equipment: Casings for devices, surgical instruments, and hospital furniture often use sheet metal for durability and easy sterilization.

-

Custom Projects: From signage to industrial equipment, sheet metal fabrication allows for tailored solutions that match unique client needs.

These applications benefit greatly from CNC metal fabrication, which ensures consistent quality and tight tolerances across all parts.

Benefits of CNC in Sheet Metal Fabrication

Using CNC technology in sheet metal fabrication brings clear advantages. First, it offers unmatched precision and repeatability—meaning every cut, bend, or form matches the design perfectly every time. This consistency is key for producing reliable parts, especially when tight tolerances matter.

CNC also boosts cost-efficiency by reducing waste. Automated machines optimize material use, minimizing scrap metal and saving money. Plus, faster setups and fewer errors mean less downtime and lower labor costs.

Another big win is the ability to handle complex designs easily. CNC metal fabrication can create detailed shapes and intricate bends that are tough with manual methods. This flexibility opens doors for custom metal components and innovative projects.

In short, CNC services in sheet metal fabrication deliver quality, save money, and expand possibilities—all essential for today’s industrial metal fabrication needs.

Choosing the Right Fabrication Partner

Picking the right partner for your sheet metal fabrication needs comes down to a few key factors:

- Experience: You want a team familiar with a wide range of projects and materials.

- Equipment: Advanced machinery like CNC metal fabrication tools ensures precision and efficiency.

- Material expertise: Knowing how to work with steel, aluminum, stainless steel, and specialty metals is critical.

- Turnaround time: Timely delivery keeps your project on track and your costs down.

At HYCNC, we bring together all these strengths. Our state-of-the-art CNC technology guarantees consistent precision and repeatability. We back up our work with strict quality assurance, so you get reliable, high-quality results every time. Plus, we tailor solutions to your specific needs, no matter how complex your custom metal components may be.

Ready to get started? Contact us for a free consultation or a detailed quote—we’re here to support your project from start to finish.

Explore our sheet metal fabrication services today to see how we can help.