Are you struggling to choose between laser, MIG, or TIG welding for your CNC project? The right welding method can make or break your project’s precision, efficiency, and budget.

As a CNC machining expert, I’ve seen how the wrong choice can lead to costly rework or compromised quality. At HYCNC, we’re here to guide you with insights drawn from real-world experience in CNC welding.

In this guide, you’ll uncover the key differences, pros, and cons of laser vs. MIG vs. TIG welding, tailored to help you pick the perfect method for your needs.

Let’s dive in!

Understanding the Basics of Each Welding Method

Laser Welding

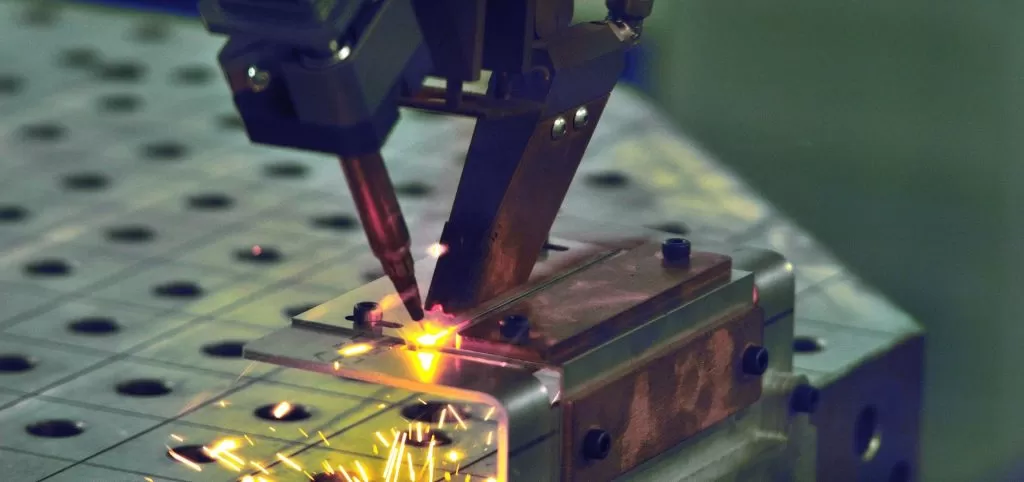

Laser welding uses a focused, high-energy laser beam to join materials with extreme precision. This method delivers intense heat in a very small area, allowing for clean, accurate welds with minimal distortion or heat-affected zones. It’s ideal for applications where fine detail and tight tolerances matter, such as in aerospace or medical device manufacturing.

MIG Welding

MIG (Metal Inert Gas) welding employs a continuous wire electrode fed through a welding gun, combined with a shielding gas to protect the molten weld pool from contamination. Known for its speed and adaptability, MIG welding is widely used in industries requiring strong, versatile joints—especially for thicker materials or high-volume production environments.

TIG Welding

TIG (Tungsten Inert Gas) welding utilizes a non-consumable tungsten electrode to create the arc, while a separate filler material is added manually if needed. This technique stands out for its exceptional control over the weld, producing clean, aesthetically pleasing results with precise heat input. TIG welding is particularly suited for thin materials and applications demanding high-quality finishes.

For more on different welding types and joints, check out our overview of the 5 basic types of welding joints.

Key Differences Laser vs MIG vs TIG Welding

Precision and Quality

Laser welding stands out for unmatched precision and causes minimal distortion, making it ideal for detailed work. MIG welding is better suited for strong, less intricate welds where speed matters more than finesse. TIG welding offers high precision and clean, aesthetically pleasing welds, perfect when appearance and quality are critical.

Speed and Efficiency

Laser welding is the fastest option for thin materials and high-volume projects, delivering quick, consistent results. MIG welding shines with thick materials and large-scale jobs thanks to its speed and continuous wire feed. TIG welding is the slowest because it relies heavily on manual control, making it less efficient for high-speed applications.

Material Compatibility

Laser welding is versatile—it works well on metals, plastics, and composites, expanding its use across industries. MIG welding is compatible with steel, aluminum, and stainless steel, making it a go-to for many metal fabrication needs. TIG welding excels with aluminum, magnesium, and copper alloys, offering superior control for these tricky metals.

Cost Considerations

Laser welding requires a high initial investment but benefits from low operational costs over time. MIG welding strikes a balance with moderate setup costs but tends to have higher operational expenses due to consumables. TIG welding often carries moderate to high costs both upfront and in ongoing use because of its complexity and slower speed.

Skill Level and Ease of Use

Laser welding is CNC-friendly and has a low learning curve, making it accessible for automation and consistent quality. MIG welding is easy to learn and semi-automatic, suitable for beginners and those needing fast production. TIG welding demands significant skill and experience to manage its precise control and produce clean welds.

For a deeper dive into welding methods, check out our detailed comparison on arc vs tig vs mig welding.

Applications in CNC Machining

Laser Welding in CNC

Laser welding is a top choice for CNC machining when precision matters. It’s ideal for industries like aerospace and medical where tiny, accurate parts are a must. Because it easily integrates with CNC systems, laser welding offers fast, automated production without sacrificing detail.

MIG Welding in CNC

MIG welding works great in CNC setups for projects needing strong, durable welds. It’s commonly used in automotive and construction parts where speed and strength are key. This method handles larger pieces well, making it a good fit for heavy-duty structural parts.

TIG Welding in CNC

TIG welding shines in CNC machining for artistic, thin, or delicate metal panels. It requires skilled operation but delivers clean, high-quality welds that look great and hold well. This makes TIG perfect for custom parts needing a flawless finish and precise control.

Pros and Cons of Each Welding Method

Laser Welding

Pros

- Highly precise with clean, minimal heat-affected zones

- Fast welding speeds, especially on thin materials

- Versatile, works well on metals, plastics, and composites

Cons

- High upfront equipment cost

- Limited penetration on very thick materials, not ideal for heavy-duty welds

MIG Welding

Pros

- Fast welding, great for large projects and thick metals

- Cost-effective both in setup and operation

- Versatile across a range of metals like steel and aluminum

Cons

- Less precise, with rougher welds compared to laser or TIG

- Produces spatter, which can mean more cleanup after welding

TIG Welding

Pros

- Delivers excellent weld quality with clean, smooth finishes

- Offers superior control, great for delicate or precise work

- Ideal for metals like aluminum and copper alloys

Cons

- Slower process due to manual control

- Requires more skill and experience to master

Each method has its strengths and weaknesses. Choosing the right one depends on your project’s precision needs, material type, and budget.

Choosing the Right Welding Method for Your Project

Factors to Consider

Picking the right welding method depends on a few key things:

- Material type and thickness: Some methods work better with certain metals or plastics. For example, TIG shines with aluminum and copper alloys, while laser welding handles a variety of metals and composites.

- Project scale and speed: If you’re working on big, thick parts, MIG welding is often your go-to for fast, strong welds. For thin, precision parts, laser or TIG welding is better, but TIG takes more time.

- Budget and skill availability: Laser welding has a higher upfront cost but low operating expenses. MIG is more budget-friendly but less precise. TIG means more expense and requires skilled operators.

Decision Matrix

Here’s a quick comparison to help you decide:

| Welding Method | Precision | Speed | Cost | Material Compatibility | Skill Level |

|---|---|---|---|---|---|

| Laser | Highest | Fastest | High initial, low ops | Metals, plastics, composites | Low-medium |

| MIG | Moderate | Fast | Moderate initial, higher ops | Steel, aluminum, stainless steel | Easy |

| TIG | High | Slow | Moderate-high | Aluminum, magnesium, copper alloys | High |

HYCNC’s Role

At HYCNC, we understand these nuances and tailor solutions to fit your project’s unique needs. Using our advanced CNC technology, we match the best welding method with your material, scale, and budget for maximum efficiency and quality.

Choosing the right welding process doesn’t have to be complicated—our expertise helps you get it right the first time.

Why Choose HYCNC for Your Welding Needs

At HYCNC, we bring deep expertise in laser, MIG, and TIG welding, so you get the right method for your project. Our advanced CNC technology ensures precision and efficiency, delivering consistent, high-quality results every time.

We don’t do one-size-fits-all. Instead, we provide tailored welding solutions that match your specific materials, budget, and project timeline. Whether you need tight, clean welds or fast, strong joins, we’ve got you covered.

Ready to get your welding project done right? Contact HYCNC for a consultation and let’s find the perfect fit for your needs.