What Is Arc Stick Welding

Arc welding, also known as stick welding, is one of the oldest and most widely used welding methods. It involves using a consumable electrode coated in flux to create an electric arc between the electrode and the base metal. This arc generates intense heat, melting both the electrode and the metal surfaces to join them together once cooled.

Process overview

- A welding power supply generates an electric current.

- The electrode is held close to the metal, forming an arc.

- The heat melts the electrode and the metal edges.

- The flux coating burns, creating a shielding gas that protects the weld from contamination.

- The molten metal solidifies, forming a strong joint.

Key features and benefits

- Versatile and can weld thick metals, even outdoors or in windy conditions without shielding gas.

- Equipment is relatively simple and portable.

- Works well on a variety of metals, including steel and cast iron.

- Cost-effective, making it a favorite for general fabrication and repair jobs.

- Great for heavy-duty and structural welding applications.

Limitations

- Produces more spatter and slag, needing cleanup after welding.

- Not ideal for thin metals due to potential burn-through.

- Requires more skill for a clean, precise weld.

- Welding speed is slower compared to MIG welding.

- Limited precision compared to TIG welding, less suited for detailed projects.

Best applications for Arc welding

- Outdoor jobs like construction and heavy equipment repair.

- Maintenance and repair on steel structures.

- Welding thick, heavy metal pieces where speed and portability matter.

- Projects where cost control is more important than weld aesthetics.

- Ideal for beginners in CNC welding techniques looking for a durable entry-level method.

Arc welding remains a reliable and economical choice for many metal fabrication welding needs, especially when working with thick metals or in challenging environments.

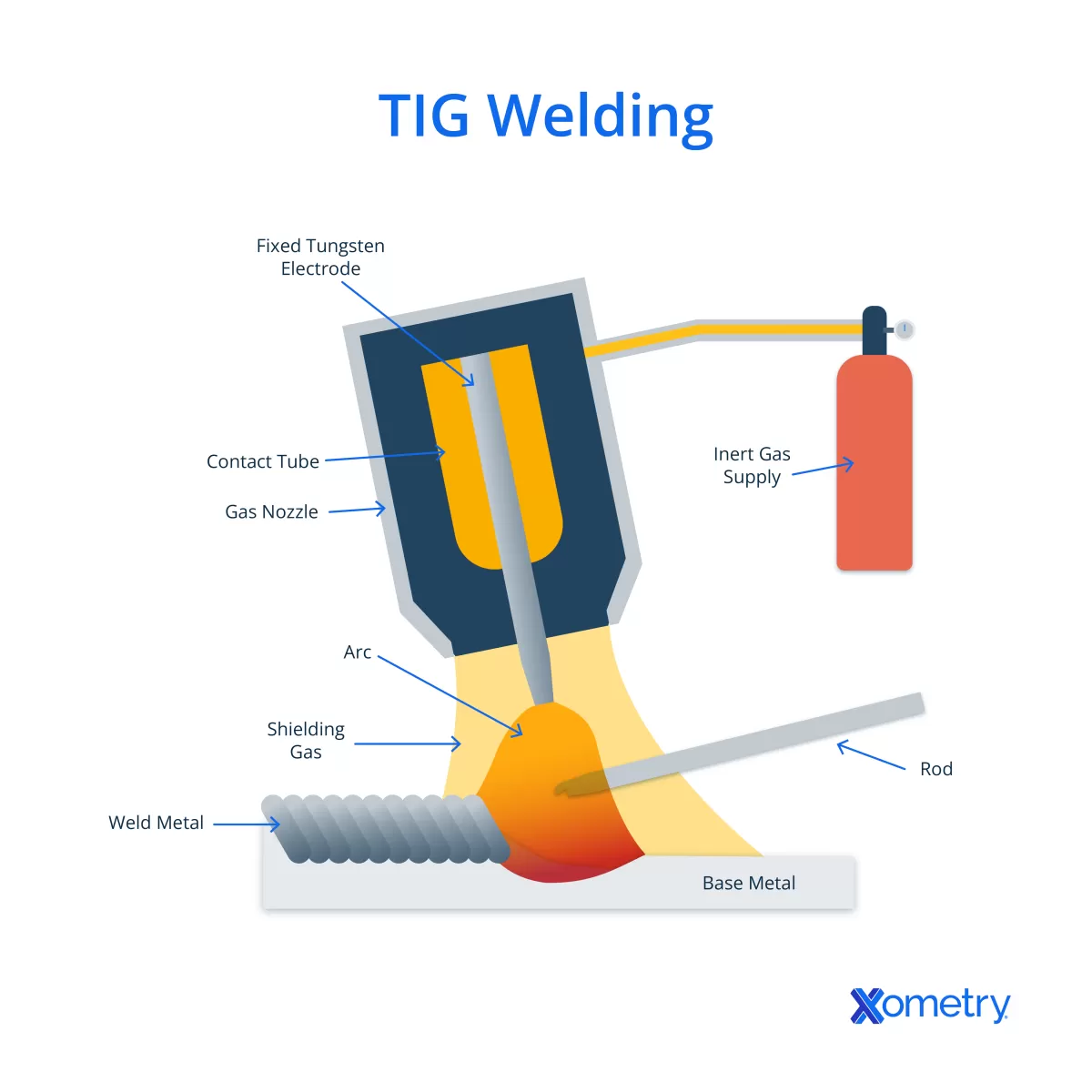

What Is TIG Welding

Definition and Process

TIG welding, short for Tungsten Inert Gas welding, uses a non-consumable tungsten electrode to create the weld. It involves feeding a separate filler metal into the weld pool while a shielding gas, usually argon, protects the weld from contamination. The process gives the welder precise control over heat and filler material, making it ideal for detailed work.

Key Features and Benefits

- Precision: TIG welding offers excellent control, allowing for clean, high-quality welds with minimal spatter.

- Versatility: It works well on thin metals and a variety of materials, including stainless steel, aluminum, and copper alloys.

- Aesthetic Finish: Produces neat, smooth welds that require less cleanup and polishing.

- Strong Welds: TIG creates durable joints that are corrosion-resistant and less prone to cracking.

Limitations

- Slow Process: TIG welding is generally slower compared to MIG or stick welding, which can increase project time.

- Skill Required: It requires a higher skill level and more practice to master since the operator must control the torch, filler rod, and foot pedal simultaneously.

- Cost: Equipment and shielding gases can be more expensive than other types, raising the initial investment.

- Not Ideal for Heavy-Duty: TIG is less suited for thick or dirty metals and outdoor environments due to sensitivity to contamination.

Best Applications for TIG Welding

- Precision work on thin metals, especially aluminum and stainless steel.

- Projects where weld appearance matters, like art pieces, bike frames, and aerospace components.

- Welding tasks requiring strong, clean welds without much post-weld finishing.

- Ideal for CNC parts that require tight tolerances and detailed welds.

For those in CNC machining and sheet metal fabrication aiming for quality and accuracy, TIG welding offers unmatched control. But if speed or thicker metals are a priority, another method might suit better. You can check out our detailed comparison of MIG vs TIG welding for more insight.

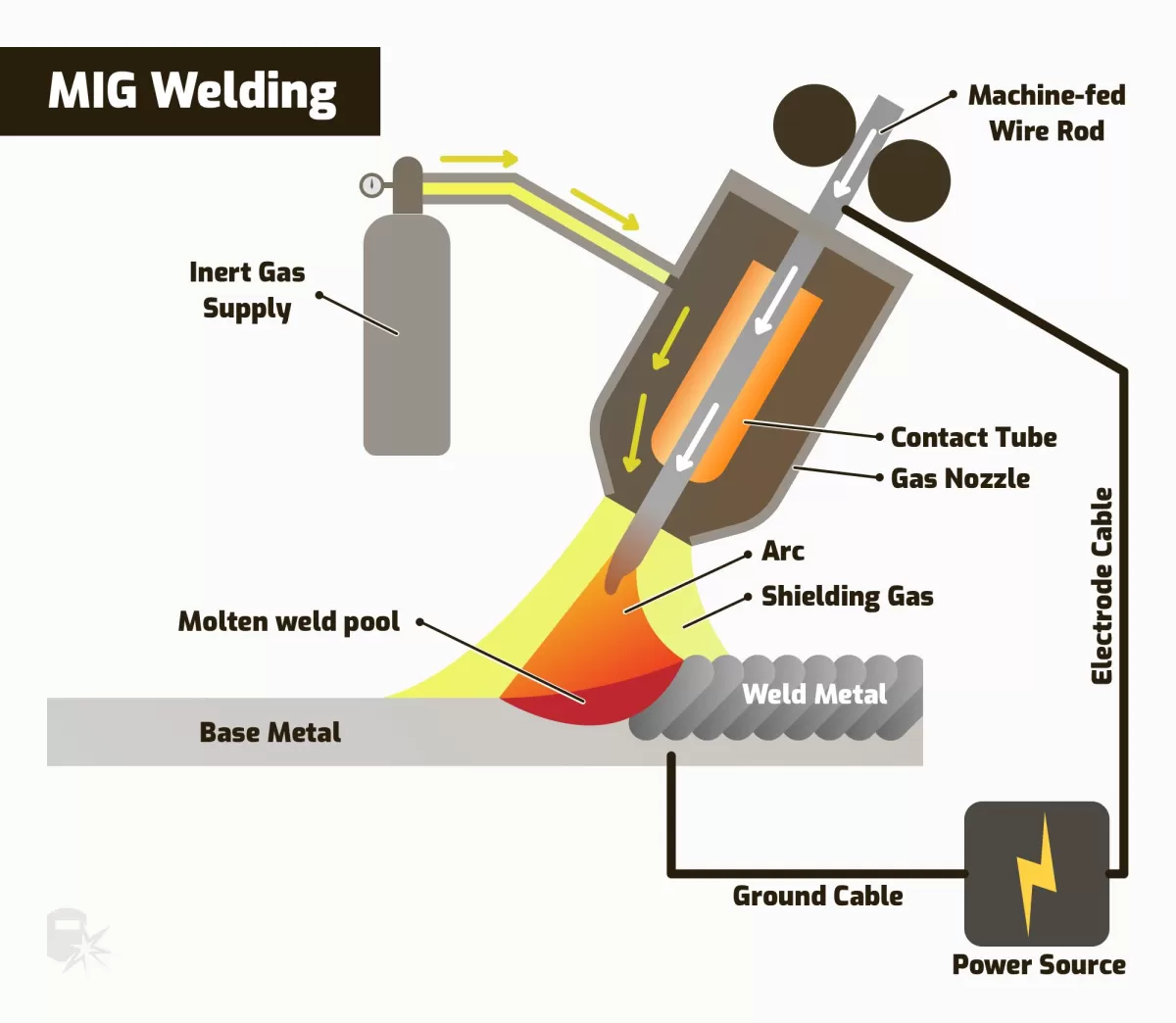

What Is MIG Welding

MIG welding, or Metal Inert Gas welding, is a popular process that uses a continuous wire electrode fed through a welding gun. It also relies on a shielding gas—usually argon or a mix of argon and carbon dioxide—to protect the weld from contamination. This method makes it easier to join metals quickly and cleanly.

Definition and Process

In MIG welding, the wire acts like both the electrode and the filler material. As the wire melts, it fuses the base metals together. The shielding gas flows around the weld area to keep it free from rust and other impurities. This results in a smooth, strong weld with less spatter compared to arc welding.

Key Features and Benefits

- Fast Welding Speed: MIG welding is one of the quickest welding options available, which helps save time on larger projects.

- Easy to Learn: Because the wire feeds automatically, it’s beginner-friendly and ideal for consistent welds.

- Clean Welds: Minimal slag and spatter mean less cleanup after welding.

- Works on Various Metals: Great for steel, stainless steel, and even aluminum if you use the right shielding gas and wire.

Limitations

- Less Ideal Outdoors: Shielding gas can blow away in windy conditions, making welds weaker.

- More Equipment Needed: You’ll need a gas tank and regulator in addition to the welder, adding cost and complexity.

- Not as Precise as TIG: If you need highly detailed or clean welds, MIG is less precise than TIG welding.

Best Applications for MIG Welding

- Sheet metal fabrication and automotive repairs where speed and efficiency matter.

- Welding thicker materials in manufacturing and heavy-duty metal fabrication.

- Aluminum welding jobs when paired with the right gas and wire.

- CNC welding techniques that demand speed without sacrificing decent weld quality.

If you want a fast, reliable welding process with clean results, especially for metal fabrication or CNC machining projects, MIG welding is a solid choice.

Arc vs TIG vs MIG A Side-by-Side Comparison

Here’s a quick look at how arc (stick), TIG, and MIG welding stack up against each other, especially for CNC projects and sheet metal fabrication.

| Feature | Arc (Stick) Welding | TIG Welding | MIG Welding |

|---|---|---|---|

| Process | Manual electrode melts metal | Uses tungsten electrode + gas | Uses wire feed + shielding gas |

| Precision | Moderate | High precision and clean welds | Good precision but less than TIG |

| Speed | Slower | Slowest | Fastest |

| Cost | Low equipment cost | Higher due to gas and setup | Moderate, more consumables |

| Skill Level | Moderate to high | High skill needed | Easier to learn, user-friendly |

| Materials | Steels, iron, less on aluminum | Steel, stainless, aluminum well | Steel, aluminum, stainless |

| Best for | Heavy-duty repairs and thick metal | Detailed, thin metals, critical welds | Production work, fast fabrication |

Key Differences

- Arc welding is tough and versatile, great for outdoor or thick metal jobs but not ideal for fine or aesthetic work.

- TIG welding excels in precision and neat welds, perfect for CNC machining parts where look and accuracy matter.

- MIG welding balances speed and ease, making it the go-to for many sheet metal fabrication jobs and high-volume CNC projects.

Choosing Based on CNC Project Needs

- If your CNC job needs speed and you’re working with stainless steel or aluminum regularly, MIG welding is your best bet.

- For projects requiring fine detail and top-notch surface finish, like custom metal art or delicate parts, go with TIG welding precision.

- When working on heavy-duty metal fabrication or outdoor repairs where cost and equipment simplicity are important, arc welding applications shine.

Each method has its place depending on your project’s priority—speed, strength, or precision. Knowing these differences will help you pick the right welding process that matches your CNC machining and metal fabrication goals.

Which Welding Method Is Right for Your CNC Project

Choosing the right welding method for your CNC project depends on your skill level, the type of work, and the results you want. Here’s a quick guide to help you decide.

For Beginners and Hobbyists

If you’re just starting out or working on small DIY projects, arc (stick) welding is a solid choice. It’s straightforward, affordable, and doesn’t require too much setup. Stick welding works well with thick metal pieces and can be done outdoors without a lot of fuss about shielding gases. Just keep in mind that it might take some practice to get clean welds.

For Precision and Aesthetics

When your CNC project calls for clean, precise welds—especially on thin materials or aluminum—TIG welding is the best pick. TIG welding gives you full control over the weld bead and produces neat, smooth results. This makes it ideal for detailed metal fabrication where appearance matters. It is slower and takes more skill but delivers high-quality, lasting welds with minimal cleanup.

For Heavy Duty and Cost-Effective Solutions

If speed and efficiency are what you need, especially for larger volume work like sheet metal fabrication, MIG welding shines. It’s faster than TIG and stick welding and easier to learn. MIG welding delivers strong welds that are good for thick metals and heavy-duty applications in CNC machining. It uses a shielding gas that protects the weld, helping reduce defects and rework.

HYCNC’s Expertise in Welding for CNC

At HYCNC, we understand that every CNC project has unique welding needs. Our team combines experience with advanced CNC welding techniques to help you choose and apply the right method. Whether you need precision TIG welds or cost-effective MIG solutions, we support your project from start to finish. For more on quality welding in CNC projects, check our insights on welding tips for laser and waterjet cut parts.

By matching the welding process to your project’s needs, you save time, reduce costs, and get the finish you’re aiming for.

Tips for Optimizing Welding in CNC Projects

Getting the best results when welding for CNC machining or sheet metal fabrication means paying attention to a few simple but important steps. Here’s how I recommend optimizing welding in your CNC projects:

-

Choose the Right Welding Method: Match the welding process (arc, TIG, or MIG) to your material and project needs. For example, use TIG welding for precision and aesthetics, MIG for speed and volume, and arc welding for simple, heavy-duty work.

-

Use Proper Shielding Gas: Shielding gas protects welds from contamination. For MIG and TIG, opt for the right mix based on metal type—argon for aluminum or stainless steel, and argon-CO2 blends for mild steel.

-

Select the Correct Electrode or Wire: Quality welding electrode types or wire size and composition must fit your material thickness and type. This improves weld strength and reduces defects.

-

Control Heat Input: Avoid warping or burning through your workpiece by adjusting amperage and welding speed. CNC projects often involve thin metals that need gentle heat control.

-

Maintain Clean Surfaces: Remove rust, oil, and dirt before welding. Clean metal helps prevent weak or porous welds that compromise metal fabrication welding quality.

-

Practice Consistent Technique: Consistent welding angle, speed, and distance lead to uniform weld beads. This consistency is key in a CNC environment where precision counts.

-

Pre-plan Your Weld Path: Using a CNC approach means pre-planning TIG or MIG welding paths can save time and improve accuracy in complex fabrications.

Following these tips will improve your welding quality and efficiency, making your CNC machining and welding projects stand out with strong, clean, and reliable joints.