What is a Die for Sheet Metal Stamping

If you’re wondering what a die for sheet metal stamping really is, here’s the straightforward answer: it’s a precision tool designed to cut, shape, and form sheet metal into specific parts.

At its core, a stamping die consists of three main components:

- Punch: The part that presses into the metal to create a shape or hole

- Die set: The base or cavity that the punch presses into, shaping the metal

- Press interaction: The machine that powers the punch and die, applying force to transform the metal

Together, these parts work seamlessly to deliver consistent, accurate shapes over and over again. This precision is crucial when you need high-volume, repeatable production, especially in industries like automotive and electronics where every inch matters. The die ensures each stamped part meets tight tolerances while streamlining manufacturing efficiency.

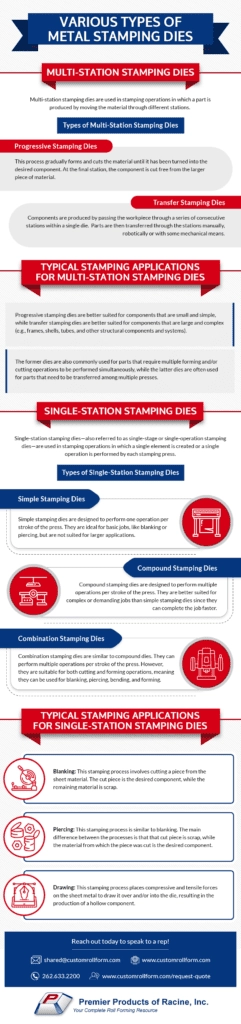

Types of Dies for Sheet Metal Stamping

Sheet metal stamping uses several types of dies, each suited for different production needs and part complexities.

-

Progressive Dies

These are perfect for high-volume jobs with complex parts. Multiple operations like cutting, bending, and punching happen in one continuous process as the sheet moves through the die, saving time and boosting efficiency.

-

Transfer Dies

Best for large, intricate components, transfer dies handle sequential operations by moving the part between different stations. This method is great when precision is crucial across multiple forming steps.

-

Line Dies

Line dies offer flexibility for smaller runs or custom jobs. They involve manual or semi-automatic handling and are suited when each operation is spaced out along a production line.

-

Compound Dies

These perform multiple cutting or forming actions in a single stroke, making them ideal for simpler parts that don’t need complex processing.

At HYCNC, we can manufacture all these die types tailored specifically to your project requirements. Whether you need precision progressive dies or flexible line dies, our CNC machining expertise ensures your die will meet high standards for performance and durability.

Key Design Considerations for Sheet Metal Stamping Dies

When designing a die for sheet metal stamping, several important factors come into play to ensure the tool performs well and lasts long.

Material Selection

Choosing the right material is critical. Durable tool steel or carbide is often used because they resist wear and keep the die sharp over time. This means fewer replacements and less downtime.

Bend Radius

Maintaining a minimum bend radius of 1 to 2 times the sheet metal’s thickness helps prevent cracking during forming. A tighter radius can cause material fatigue or breakage.

Hole Placement

Position holes at least 2 times the material thickness away from edges. This spacing reduces the risk of deformation or tearing near cutouts, ensuring stronger, quality parts.

Tolerances

Precision matters, but you have to balance it with cost. Typical stamping die tolerances range from ±0.001” to ±0.015”. Tight tolerances improve part accuracy but increase manufacturing costs.

Springback

Sheet metal tends to spring back slightly after bending due to its elasticity. Designing dies with springback in mind lets you compensate for this, delivering parts that meet exact specifications.

Working with Experts Like HYCNC

To get the best die design that fits your needs, it’s wise to collaborate with CNC experts like HYCNC. Their experience in tool design and CNC machining helps optimize everything—from tolerances to materials—saving you time and money while boosting performance.

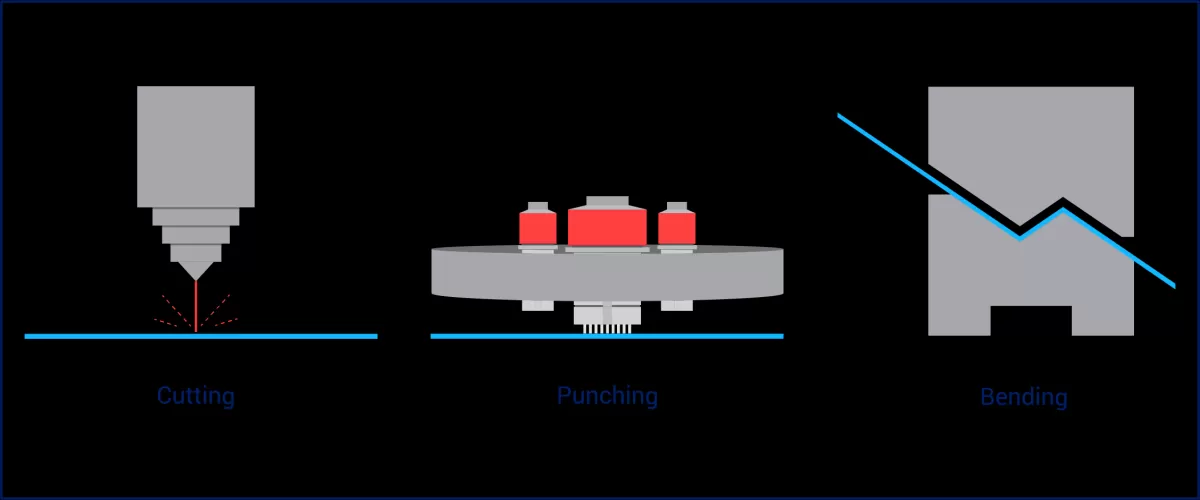

The Sheet Metal Stamping Process with Dies

Sheet metal stamping involves several key stages to turn flat metal sheets into precise parts. These stages include blanking, piercing, bending, forming, and coining. Each stage relies on specialized dies to shape and cut the metal accurately, keeping parts consistent and within tight tolerances.

- Blanking cuts the raw sheet metal into manageable pieces using a blanking die.

- Piercing punches holes or shapes out of the metal with piercing dies.

- Bending uses bending dies to form angles and curves without cracking the metal.

- Forming shapes the metal into 3D components through gradual die pressure.

- Coining adds fine details or embossing by pressing the metal between precise dies.

At every step, dies maintain precision and repeatability, ensuring each part matches the design exactly.

HYCNC’s advanced CNC technology takes die manufacturing to the next level by producing tools with tight tolerances and superior surface finishes. This precision helps reduce material waste, speeds up cycle times, and improves the overall quality of stamped parts—making it a smart choice for anyone needing dependable sheet metal stamping dies.

Benefits of Using High Quality Dies from HYCNC

Choosing high quality dies from HYCNC means better precision and consistent results, especially for complex sheet metal parts. Our dies deliver tight tolerances, so every piece matches your design perfectly, reducing errors and scrap.

Using our dies also cuts down material waste, helping you save on costs while keeping production lean. Faster cycle times are another advantage—our expertly crafted dies work smoothly with your presses, speeding up the stamping process and boosting overall efficiency.

Plus, we tailor custom stamping dies to fit industries like automotive, aerospace, and electronics, meeting their specific needs and tight industry standards. When you partner with HYCNC, you get durable, reliable sheet metal stamping dies that improve your production from start to finish.

Common Challenges in Die Design and How HYCNC Solves Them

Designing dies for sheet metal stamping comes with its share of challenges. At HYCNC, we understand these issues and tackle them head-on to deliver reliable, long-lasting tools.

Wear and Tear

Stamping dies go through a lot of stress. Using durable tool steels and carbide materials helps extend die life. We also use advanced simulation software to predict wear points before production starts, so we can reinforce weak spots and avoid unexpected failures.

Springback Control

Springback happens when metal tries to return to its original shape after forming, causing parts to be out of spec. Our engineers factor in material elasticity and refine die geometry precisely to minimize springback, ensuring parts come out accurate every time.

Optimizing Die Maintenance

A die’s performance naturally declines over time without proper upkeep. We help clients set up maintenance schedules and use wear-resistant coatings to keep dies running longer. Plus, our CNC technology makes repairing and refurbishing dies faster and more cost-efficient.

By addressing these common challenges with smart engineering and technology, HYCNC helps you keep your sheet metal stamping process smooth and productive.

How to Choose the Right Die for Your Project

Picking the right die for your sheet metal stamping job comes down to a few key factors:

- Material Type: Different metals like aluminum, steel, or copper behave differently during stamping. Your die needs to match the hardness, thickness, and flexibility of the material.

- Part Complexity: Simple parts might just need a compound die, while complex shapes with multiple steps require progressive or transfer dies.

- Production Volume: High-volume runs call for durable dies designed for repeated use and fast cycle times, whereas low volume might favor more flexible or customizable die options.

Partnering with a trusted CNC provider like HYCNC is crucial. We bring deep know-how in CNC die manufacturing and sheet metal fabrication tools to help tailor your die design to your exact needs. That means better precision, fewer costly mistakes, and quicker turnarounds.

Here’s how to work with HYCNC for your custom die solutions:

- Share your project details, including material specs and part drawings.

- Discuss your production goals and volume expectations.

- Collaborate on design options and get recommendations based on our experience.

- Review prototypes and iterate if needed before full production.

- Rely on our support for die maintenance and any adjustments down the line.

Choosing the right die and partner makes your sheet metal stamping project smoother, more efficient, and cost-effective. At HYCNC, we’re ready to help you find the perfect fit.

Why HYCNC for Your Sheet Metal Stamping Dies

When it comes to sheet metal stamping dies, HYCNC stands out because of our advanced CNC machining capabilities. We deliver precision die manufacturing that meets tight tolerances and complex designs, ensuring your parts come out exactly as planned every time.

We’ve worked with a wide range of industries—including automotive, aerospace, and electronics—so we understand the unique challenges each sector faces. That means we can tailor our custom stamping dies to fit your specific needs, no matter the project size or complexity.

At HYCNC, quality and efficiency are at the core of everything we do. We use durable materials and the latest technology to provide dies that last longer and perform better. Plus, our team is committed to delivering excellent customer service and fast turnaround times to keep your production moving smoothly.

Ready to improve your sheet metal fabrication tools? Contact HYCNC today for a consultation or a quote and let us help you bring your stamping die projects to life.