What is Centrifugal Casting

Centrifugal casting is a specialized casting process that uses centrifugal force to produce cylindrical metal parts. In simple terms, molten metal is poured into a mold that spins rapidly. The spinning action pushes the metal outward against the mold walls, creating a solid, dense part as it cools and hardens.

Here’s how it works:

- Molten metal is poured into a rotating mold.

- The mold spins at high speed, generating centrifugal force.

- This force pushes the metal toward the mold’s outer edge, ensuring tight contact.

- As the metal cools, it solidifies under high pressure, leading to a strong, uniform structure.

The key components in this process are the spinning mold, the molten metal, and the principle of directional solidification, where metal cools from the outside inward, reducing defects.

Centrifugal casting has a rich history. It was first developed in the early 19th century by A.G. Eckhardt, who laid the groundwork for what is now a critical technique in manufacturing high-strength, cylindrical parts like pipes and rings. This early innovation set the stage for modern centrifugal casting used across many industries today.

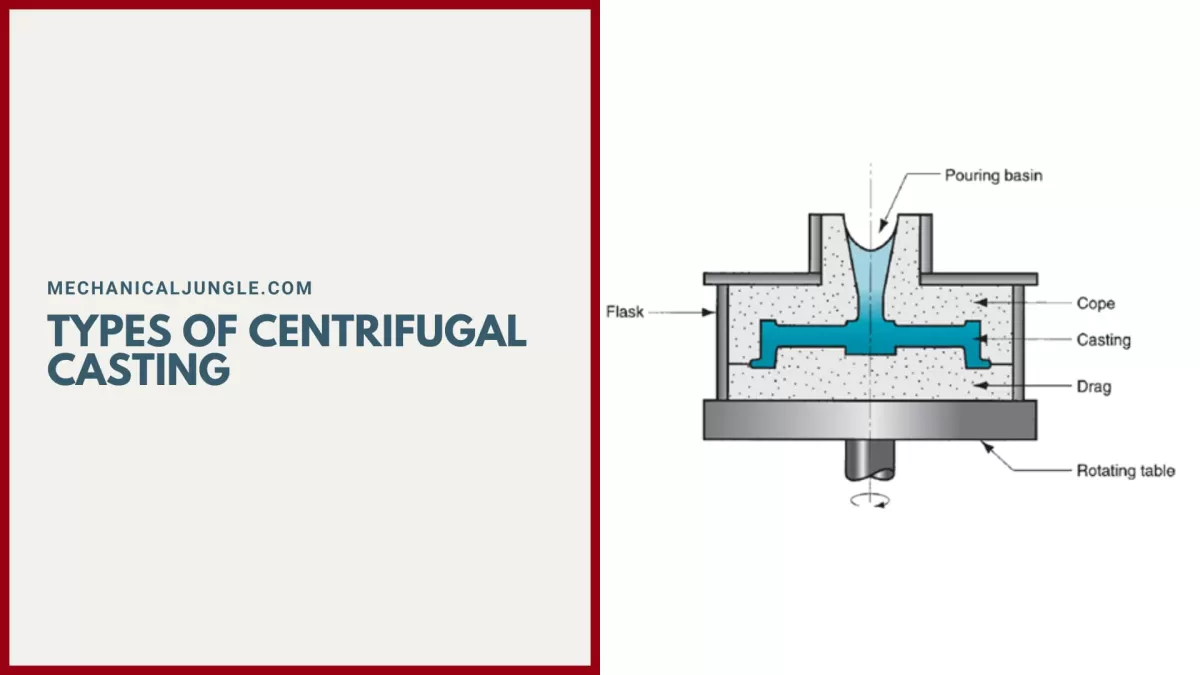

Types of Centrifugal Casting

Centrifugal casting comes in a few main types, each suited for different applications:

-

True Centrifugal Casting

This type spins molten metal inside a rotating mold to create hollow cylindrical parts like pipes and tubes. No core is needed because the metal forms the shape as it’s forced outward by centrifugal force.

-

Semi-Centrifugal Casting

Here, a central core is used inside the spinning mold. This process is perfect for making solid, disc-shaped parts such as gears and flywheels, giving precise inner dimensions.

-

Centrifuging

This technique casts small, detailed parts by pouring metal into multiple molds arranged around a central axis. It’s great for intricate shapes and smaller components often found in industrial casting applications.

-

Horizontal vs Vertical Casting

Mold orientation matters:

- Horizontal casting is ideal for long, thin cylinders like pipes.

- Vertical casting suits shorter, wider parts like rings and bushings.

The choice depends on part shape, size, and the metal used.

Each method has its strengths, and understanding these helps ensure the best outcome for your precision casting needs.

Benefits of Centrifugal Casting

Centrifugal casting offers several advantages that make it a go-to choice for many industries in the U.S. First, it delivers superior material integrity. The process creates a dense, fine-grained metal structure with very few defects like porosity or inclusions. This means stronger, more reliable parts.

It’s also cost-effective because it minimizes material waste. Since the molten metal spreads evenly thanks to centrifugal force, you get nearly full use of the metal poured, cutting down on excess and reducing the need for costly machining afterward.

Another big plus is high strength. Directional solidification during casting aligns the metal grain structure in a way that boosts mechanical properties, producing components that can withstand heavy-duty applications.

Finally, centrifugal casting is incredibly versatile. It works well with a wide range of materials, including metals, alloys, glass, and even concrete. This flexibility makes it popular across aerospace, automotive, and energy sectors, all of which demand high-reliability components ready to perform under tough conditions.

Applications of Centrifugal Casting

Centrifugal casting is widely used across various industries because it creates strong, durable parts with excellent material properties. Here’s where you’ll often find it:

- Aerospace: Parts like turbine blades and compressor cases benefit from the high strength and precision of centrifugal casting.

- Automotive: Cylinder liners and piston rings are commonly made this way for their wear resistance and exact fit.

- Energy: Petrochemical plants rely on furnace tubes and reformer tubes cast centrifugally to handle high temperatures and corrosion.

- Industrial: Pipes, bushings, bearings, and other cylindrical components come from this process due to its consistent quality.

At HYCNC, we support these industries by providing precision CNC machining services that ensure cast parts meet tight tolerances and perform reliably. Our expertise in finishing centrifugal castings helps improve dimensional accuracy, surface finish, and overall part performance, making sure your critical components are ready for demanding applications.

Horizontal vs Vertical Centrifugal Casting

In centrifugal casting, the mold can spin either horizontally or vertically, and each has its advantages depending on the part you need.

Horizontal Casting is great for making long, thin cylinders like pipes and tubes. The mold spins around a horizontal axis, which helps produce consistent wall thickness perfect for things that need to be long and hollow.

Vertical Casting works better for short, wide parts such as rings, bushings, or flanges. Here, the mold spins around a vertical axis, making it easier to control solidification for these shapes.

Factors That Affect Your Choice

- Part dimensions: Longer parts usually favor horizontal casting, while shorter, wider parts suit vertical casting better.

- Mold design: The mold’s shape and how it handles the metal flow can influence the best orientation.

- Material properties: Some metals or alloys may respond differently depending on the casting direction because of cooling rates and solidification patterns.

How HYCNC Supports Both Processes

At HYCNC, we have the precision CNC machining capabilities to handle parts made by both horizontal and vertical centrifugal casting. Whether it’s refining a long pipe or finishing a ring, we provide accurate machining to meet tight tolerances and demanding specifications for industries like aerospace, automotive, and energy.

Challenges and Limitations of Centrifugal Casting

Centrifugal casting is a powerful process, but it comes with some challenges you should know about:

- Potential Defects: Porosity and uneven solidification can occur if the process isn’t optimized. This affects material strength and surface finish.

- High Mold Costs: Permanent molds needed for centrifugal casting require a big upfront investment, which can be a barrier for some projects.

- Process Control: Getting the rotation speed, temperature, and cooling rate just right is critical. Too much or too little in any can lead to defects or weak spots.

At HYCNC, we solve these issues by combining our advanced CNC machining precision with real-time process control. This helps us ensure your parts meet strict quality standards and reduces waste, making the centrifugal casting process more reliable and efficient.

For related casting services, check out our metal casting solutions that support a variety of industrial applications.

Innovations in Centrifugal Casting

Centrifugal casting has evolved with smart tech to boost quality and efficiency. Today, real-time monitoring with sensors allows us to track the casting process closely, catching defects early and ensuring each piece meets top standards.

3D printing is a game changer for creating complex mold designs quickly and affordably. This opens doors to more intricate shapes and faster prototyping, perfect for custom or small-batch runs.

We’re also seeing advances in high-temperature alloys and ceramics, which let castings perform better under extreme conditions. These materials are critical for aerospace, automotive, and energy parts that need superior strength and heat resistance.

At HYCNC, we combine these innovations with our expert CNC machining. This means we can handle post-casting finishing with precision, delivering flawless components ready for your demanding applications. Our skill in integrating new tech keeps us at the forefront of quality and efficiency in centrifugal casting.

Why Choose HYCNC for Centrifugal Casting Needs

When it comes to centrifugal casting, finishing is just as important as the casting itself. At HYCNC, we bring expert CNC machining to the table, ensuring every part meets tight tolerances and complex specifications. Whether you need precision engineering for aerospace turbine components or durable automotive cylinder liners, we deliver the quality and accuracy you expect.

We understand the unique demands of the aerospace, automotive, and energy industries, so we offer customized solutions designed to fit your exact requirements. Our team focuses on maximizing efficiency and minimizing waste, helping you reduce costs without compromising on performance.

Plus, we’re committed to sustainable practices that benefit both your business and the environment. With HYCNC handling your post-casting machining needs, you get a reliable partner focused on quality from start to finish.

Ready to take your centrifugal casting projects to the next level? Contact HYCNC today for a quote or consultation. Let’s discuss how our CNC machining expertise can support your production goals.