What is TIG Welding

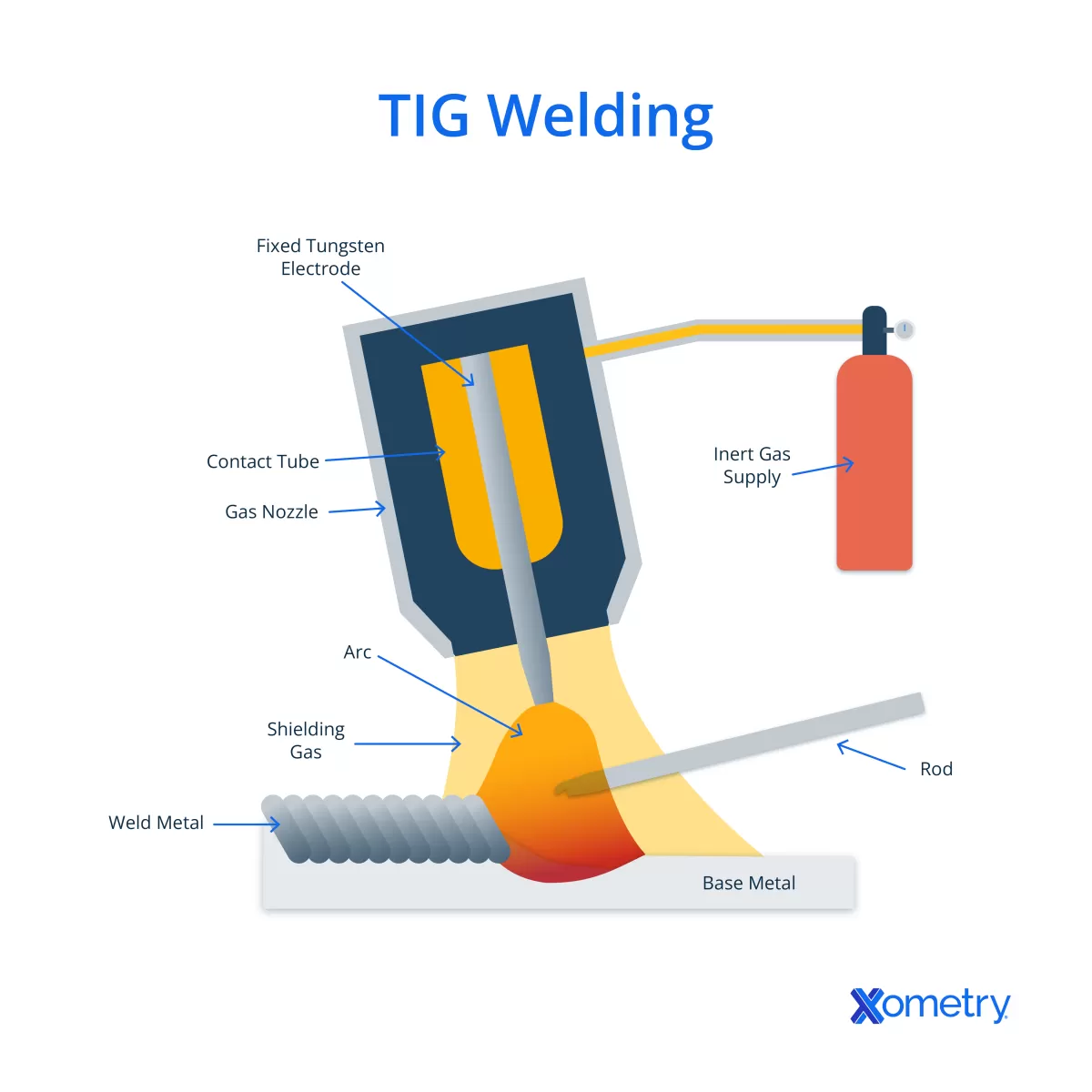

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is a precise welding method that uses a non-consumable tungsten electrode to create the arc. The process relies on an inert gas, usually argon, to shield the weld area from contamination. A welding torch holds the tungsten electrode, while filler material is added manually if needed.

This method stands out due to its ability to produce clean, high-quality welds with excellent control over heat and weld shape. Compared to other welding techniques like MIG or stick welding, TIG welding offers superior precision, making it ideal for delicate work with thin metals.

TIG welding has a long history dating back to the 1930s when it was first developed for welding magnesium and aluminum. Since then, it has become essential in industries requiring strong, reliable, and aesthetically pleasing welds, such as aerospace, automotive, and medical manufacturing.

How Does the TIG Welding Process Work

TIG welding, also called Gas Tungsten Arc Welding (GTAW), uses a non-consumable tungsten electrode to create the arc that melts the metal. Here’s how the process typically goes:

- Setup: You start by installing a tungsten electrode into the welding torch. This electrode stays solid and doesn’t melt during welding.

- Shielding Gas: An inert gas like argon flows through the torch to protect the weld area from contaminants in the air. This shielding gas is key to a clean weld.

- Preparing the Workpiece: Clean surfaces are critical. Dirt, oil, or rust can weaken the weld or cause defects, so prepping the metal beforehand makes a big difference.

- Arc Creation: When you strike the arc between the tungsten electrode and the workpiece, it generates intense heat that melts the metal at the weld joint.

- Weld Pool Formation: The melted metal forms a small pool where you add filler rod if needed to build the joint. This pool solidifies into a strong, clean weld.

- Shielding Role: The inert gas continuously blankets the weld pool, preventing oxidation and other reactions that would compromise strength and appearance.

- Foot Pedal Control: Many TIG setups include a foot pedal that allows you to adjust the welding current on the fly. This lets you control heat precisely, especially useful on thin or delicate materials.

Overall, TIG welding requires attention to detail, especially keeping surfaces clean and controlling the arc and gas flow, to produce high-quality welds.

Key Benefits of TIG Welding

TIG welding stands out for its precision control, making it perfect for thin materials and intricate designs where accuracy matters. This process creates clean welds with minimal spatter, giving every job a professional, polished finish. Its versatility lets you weld a wide range of metals, including aluminum, stainless steel, and more.

When it comes to strength and durability, TIG welds hold up well over time and resist corrosion, which is important for many industrial and manufacturing needs. Plus, TIG welding is more eco-friendly compared to other methods because it produces fewer fumes, contributing to a safer work environment.

In short, TIG welding offers:

- Precise control for detailed and delicate work

- Clean, spatter-free welds for a better look and less cleanup

- Versatility across many metals and thicknesses

- Strong, durable welds resistant to corrosion

- Lower fume production, helping keep air quality better onsite

These benefits make TIG welding a solid choice for anyone looking for quality, reliability, and well-finished results.

Applications of TIG Welding in CNC Manufacturing

TIG welding plays a big role in CNC manufacturing, especially when precision and quality matter. In aerospace, it helps create lightweight, high-strength parts that can handle tough conditions. For the automotive industry, TIG welding is perfect for exhaust systems, chassis components, and other precision parts that need clean, strong welds.

In medical and pharmaceutical fields, TIG welding ensures hygienic welds free of contaminants—critical for equipment and tools. Pipe welding benefits from the process too, offering leak-free joins essential in petrochemical and energy industries where safety and durability are top priorities.

Beyond industrial use, TIG welding is popular for art and sculpture, allowing creators to work with different metals and fine details. Local CNC providers like HYCNC support these needs by delivering custom CNC parts welded with precision, combining the power of CNC machining with expert TIG welding for outstanding results.

Challenges and Considerations

TIG welding is a precise process, but it comes with some challenges you should know about. First, there’s a steep learning curve—it requires high skill and good hand-eye coordination. Because it’s slower than other methods like MIG welding, your labor costs might be higher, and the deposition rate is lower, meaning less weld material laid down per minute.

The equipment costs can also be higher since you need quality TIG welding machines, tungsten electrodes, and an inert gas supply, usually argon. Safety is another big part. TIG welding produces intense UV radiation and hot sparks, so proper PPE (personal protective equipment) like gloves, helmets, and protective clothing is a must. Since inert gases are used as shielding, ensuring good ventilation is key to avoid gas buildup.

Here are some tips to overcome these challenges:

- Get proper training to build skill and confidence

- Use high-quality, well-maintained equipment

- Follow strict safety protocols including PPE usage

- Ensure your workspace has adequate ventilation

- Take time to clean and prepare each workpiece for better results

By paying attention to these considerations, you can maximize the benefits of TIG welding without compromising safety or quality.

HYCNC’s TIG Welding Services for CNC Precision

At HYCNC, we specialize in providing top-quality TIG welding services tailored for CNC precision work. Our team brings deep expertise in handling high purity tungsten electrode welding, ensuring clean, precise welds every time. We serve key industries like aerospace and medical manufacturing, where strength, durability, and flawless finishes are critical.

One recent project involved welding intricate aerospace parts needing tight tolerances and leak-proof joints. We delivered on time with exceptional quality, helping our client meet their performance goals. With HYCNC, you get customized TIG welding solutions designed to fit your exact CNC machining needs.

If you want professional, reliable TIG welding for your next project, reach out to us. We’re ready to support your production with precision and expertise, no matter the complexity. Contact HYCNC today to discuss how we can help with custom CNC parts and welding services.

Best Practices for Effective TIG Welding

To get the best results with the TIG welding process, follow these key practices:

-

Surface Preparation and Cleaning

Always start with clean metals. Dirt, oil, or rust can cause weak or contaminated welds. Use a wire brush or grinder and clean any grease with a solvent.

-

Choosing the Right Tungsten Electrode

Pick the right tungsten electrode for your material and welding current. Common types include pure tungsten for AC welding and thoriated or lanthanated tungsten for DC welding.

-

Using Proper Shielding Gas

Argon is the most common inert gas for TIG welding. It protects the weld from contamination and helps create a stable arc.

-

Optimizing Welding Parameters

Balance your welding current, voltage, and gas flow for the specific metal and thickness. Proper speed keeps the weld pool consistent and prevents defects.

-

Controlling Gas Flow

Maintain optimal gas flow—too low lets in air, too high wastes gas and causes turbulence. Usually, 15-20 cubic feet per hour is a good range.

-

Equipment Maintenance

Keep your torch, cables, and gas supply clean and leak-free. Check tungsten tips regularly and sharpen as needed.

-

Consistent Performance

Practice steady hand movements and use foot pedals smoothly to control heat input precisely.

-

Quality Control and Testing

Always inspect welds for cracks, porosity, or other defects. Use leak tests and non-destructive testing methods to ensure strength and reliability.

By following these best practices, you can ensure clean, strong, and precise welds every time.

FAQs

What is the difference between TIG and MIG welding?

TIG welding uses a tungsten electrode and inert gas to create a clean, precise weld, ideal for thin metals and detailed work. MIG welding uses a consumable wire electrode and is faster, better for thicker materials and high-volume jobs.

Which metals can TIG welding handle?

TIG works well with aluminum, stainless steel, copper, and other non-ferrous metals, offering strong and clean welds especially on thin or delicate materials.

Why is TIG welding more expensive?

TIG welding requires skilled operators, slower welding speed, and specialized equipment, which increases labor and equipment costs compared to faster processes like MIG.

How does TIG welding affect weld quality?

TIG welding produces clean, precise welds with minimal spatter and strong bonds, making it perfect for jobs where appearance and strength matter.

What safety precautions should I take with TIG welding?

Always wear proper PPE including gloves, a helmet with UV protection, and use good ventilation to avoid fumes. TIG welding emits UV radiation, so protecting skin and eyes is important.