Precision Laser Cutting Services for Aluminum by HYCNC

Looking for high-quality laser cut aluminum services? At HYCNC, we specialize in precision laser cutting tailored to aluminum materials. Our advanced CNC laser systems deliver clean, accurate cuts that meet tight tolerances, perfect for everything from intricate prototypes to full-scale production runs. Whether you need custom aluminum parts or precise sheet metal fabrication, HYCNC combines cutting-edge technology with decades of expertise to ensure your project gets done right—on time and within budget. Trust us to handle your aluminum laser cutting needs with professionalism and unmatched attention to detail.

Why Choose Laser Cutting for Aluminum

Laser cutting aluminum is a high-precision, non-contact manufacturing process. It’s perfect for creating complex shapes and intricate designs that other methods struggle to achieve. Since the laser beam doesn’t touch the material, there’s no tool wear or distortion, which helps keep details sharp and consistent.

The main benefits include:

- High accuracy, allowing precise cuts down to tight tolerances

- Minimal material waste thanks to a thin kerf and precise control

- Smooth, clean edges often requiring little to no post-processing

- Ideal for both prototyping and large-scale production, offering speed and repeatability

At HYCNC, we specialize in aluminum laser cutting as part of our CNC processing services. With deep expertise and advanced equipment, we handle projects ranging from custom parts to full production runs, delivering reliable results every time.

How Does Aluminum Laser Cutting Work

Aluminum laser cutting uses a CNC-controlled laser beam that precisely melts or vaporizes the metal, following your CAD or CAM files. This non-contact process ensures clean, accurate cuts every time.

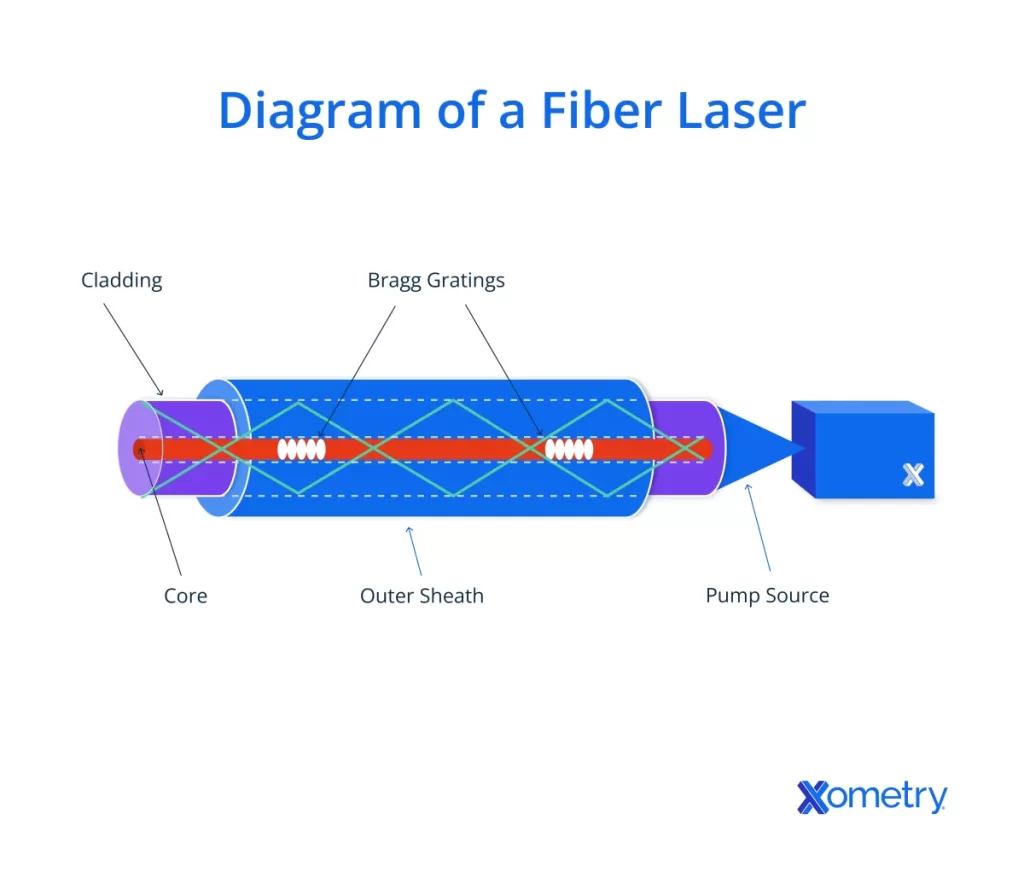

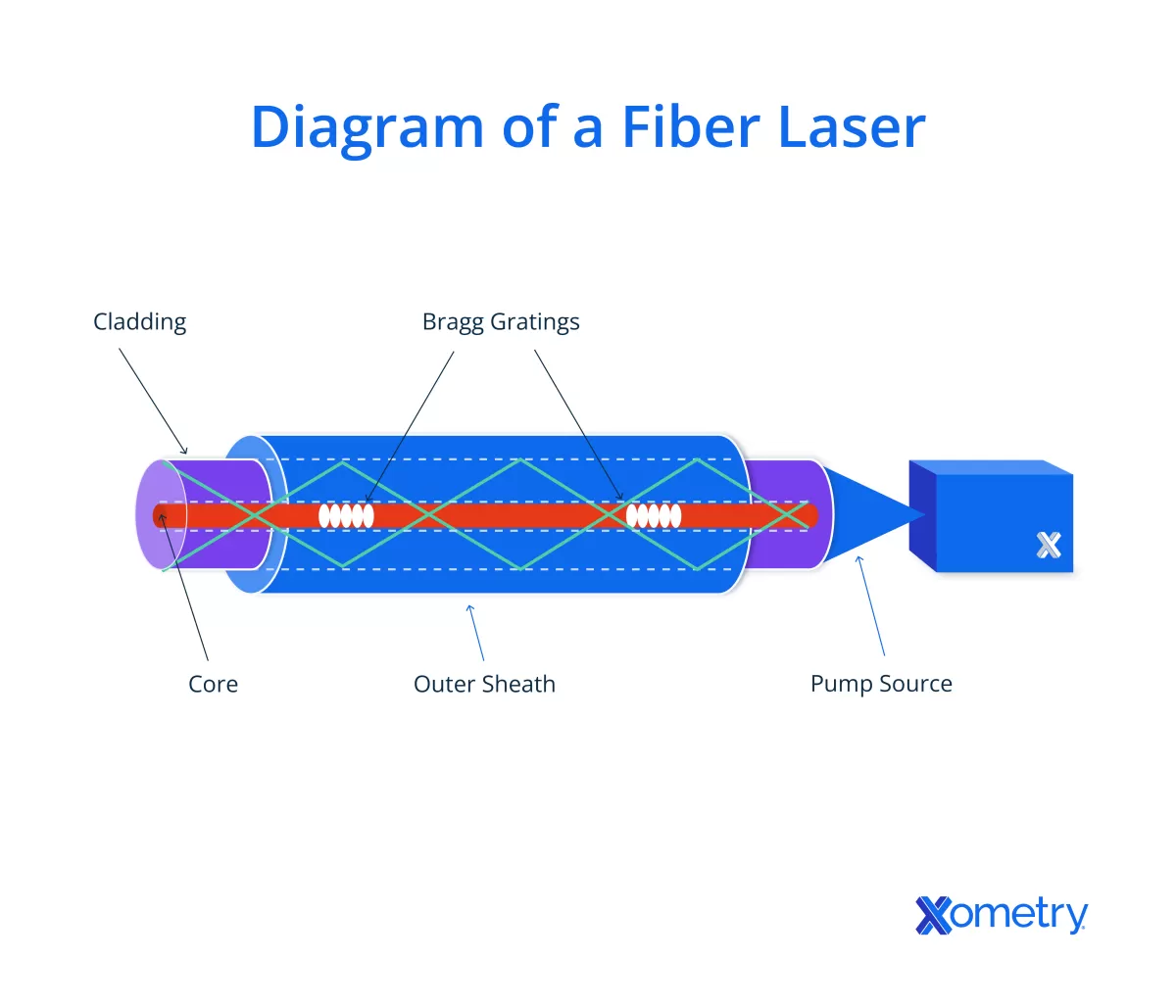

There are two main types of lasers used: fiber lasers, which work great on reflective aluminum surfaces, and CO2 lasers, better suited for cutting thicker aluminum materials. Both deliver high precision but target different thicknesses and finishes.

Assist gases like nitrogen play an important role by blowing away molten material and preventing oxidation, which helps keep edges smooth and clean without discoloration. This combination of laser technology and assist gases ensures top-notch results for aluminum laser cutting.

Advantages of HYCNC’s Aluminum Laser Cutting Services

At HYCNC, we deliver precision aluminum laser cutting with tight tolerances as small as ±0.005 inches. This lets you get intricate designs with minimal kerf width, so parts fit perfectly every time.

Our service is highly versatile, capable of cutting a wide range of aluminum alloys and thicknesses up to 4 inches. Whether you need thin sheets or thick plates, we can handle your project with ease.

We pride ourselves on speed—fast turnaround times for both prototypes and large-scale production runs keep your schedule on track.

When it comes to customization, we support multiple file formats including DXF, DWG, and SVG for smooth, hassle-free design integration.

Plus, our commitment to quality assurance means you’ll get clean cuts with minimal need for post-processing, combined with high-quality surface finishes that meet industry standards.

If you’re looking for reliable, high-precision custom aluminum parts or industrial laser cutting services, HYCNC’s aluminum laser cutting is built to meet your demands.

Applications of Laser Cut Aluminum

Laser cut aluminum is widely used across many industries in the United States. Key sectors include aerospace, automotive, architecture, and electronics, where precision and durability are crucial.

Common uses of laser cut aluminum include:

- Sheet metal parts for machinery and equipment

- Custom components tailored to specific designs

- Decorative panels that combine function with style

- Structural elements that need strength and light weight

Some real-world examples are aircraft frames, automotive body parts, and detailed signage. These applications benefit from the accuracy, clean edges, and quality finishes that aluminum laser cutting provides.

Challenges and Solutions in Aluminum Laser Cutting

Cutting aluminum with lasers isn’t without its challenges. Aluminum’s high reflectivity can bounce laser beams away, making it tough to cut cleanly. Plus, its high thermal conductivity means heat spreads fast, which can cause warping or rough edges if not handled right.

At HYCNC, we tackle these issues with advanced fiber laser technology that’s fine-tuned for aluminum’s unique properties. Our expert team adjusts cutting parameters precisely to avoid warping and edge defects. We also use nitrogen as an assist gas, which helps prevent oxidation and keeps cuts clean and smooth. This combination ensures high-quality results even with tricky aluminum alloys.

Why HYCNC for Your Aluminum Laser Cutting Needs

At HYCNC, we use state-of-the-art CNC laser cutting machines designed for high precision and efficiency. Whether you need tight tolerances or complex shapes, our equipment delivers consistent, clean cuts every time.

We offer instant online quotes, making it easy for you to get pricing quickly and plan your project without delays. Plus, we provide fast delivery options to both local and global clients, so you get your parts when you need them.

Our experienced team brings over 20 years of expertise in CNC machining and laser cutting, specializing in aluminum. That means we understand the nuances of aluminum laser cutting and provide solutions that avoid common issues like warping or edge defects.

Best of all, HYCNC focuses on offering cost-effective aluminum laser cutting services without cutting corners on quality. You get precision aluminum cutting and expert support that fits your budget and timeline.

For related services, check out our aluminum extrusion or laser cut steel capabilities to complement your project needs.

Design Tips for Laser Cutting Aluminum

To get the best results from aluminum laser cutting, here are some design tips to keep in mind:

- Use vector files like DXF or SVG for clean, precise cuts. These formats work seamlessly with CNC laser cutting machines.

- Keep engraving minimal in your design to speed up production and reduce costs.

- Consider material thickness and bend radius carefully. Thicker aluminum and tight bends can cause distortion or warping if not planned properly.

- Leverage HYCNC’s design assistance. Our team helps optimize your designs for manufacturability, ensuring smooth cutting and high-quality parts.

Following these tips will help streamline your project and get you custom aluminum parts that meet your exact needs.

Get Started with HYCNC’s Laser Cutting Services

Getting started with HYCNC’s aluminum laser cutting services is simple. Just upload your CAD file—whether it’s DXF, DWG, or SVG—to get an instant quote online. If you need custom solutions or have specific project requirements, reach out to our team. We’re here to help you find the best options for your design and production needs.

Ready to bring your project to life? Start your aluminum laser cutting with HYCNC today and experience precision, speed, and quality you can rely on.