Understanding Surface Finish vs Surface Finishing

When working with CNC machined parts, you might wonder about the difference between surface finish and surface finishing. These terms sound similar but focus on different aspects of the final product.

Defining Surface Finish

Surface finish refers to the texture, smoothness, and overall appearance of a part’s exterior after machining. It’s a measurable attribute that describes how rough or smooth the surface is, often evaluated by surface roughness values. The surface finish affects not only the look but also the performance and lifespan of the part, influencing factors like friction, wear, and corrosion resistance.

Surface Finishing Processes

Surface finishing, on the other hand, is the set of processes used to achieve or improve that surface finish. It involves various techniques applied after CNC machining to refine, protect, or enhance the raw surface. This can include mechanical methods like grinding and polishing, or chemical treatments such as anodizing and passivation. The right surface finishing process helps meet specific requirements for appearance, durability, and functionality.

Key Surface Finishing Techniques for CNC Machined Parts

When it comes to CNC surface finishing, there are several techniques to choose from depending on the look, feel, and protection you want for your parts. Here’s a quick overview of the main methods.

Mechanical Finishing Methods

- Grinding: This process uses abrasive wheels or belts to smooth out surfaces and reduce surface roughness. It’s great for achieving precise finishes on CNC components.

- Polishing: Polishing makes machined parts shiny and smooth, improving both appearance and corrosion resistance.

- Bead Blasting: Tiny glass or ceramic beads are blasted onto the surface, creating a matte or satin finish. This technique is popular for creating a consistent bead blasting finish on aluminum or steel parts.

- Wet Sanding: Using water with sandpaper, wet sanding reduces small imperfections and prepares surfaces for further finishing or coating.

Chemical and Electrochemical Finishes

- Anodizing: A common anodizing CNC parts finish that enhances corrosion resistance, improves surface hardness, and allows for color customization.

- Electropolishing: This electrochemical process removes microscopic layers, polishing metal parts to a bright, clean finish while improving corrosion resistance.

- Passivation: Often used on stainless steel, passivation removes surface contaminants and enhances the natural oxide layer, protecting parts from rust and corrosion.

- Chromate Coating: A thin, protective film applied mainly to aluminum parts to increase corrosion resistance and paint adhesion.

Coating Based Finishes

- Powder Coating: This method applies a dry powder that’s baked on, creating a durable, color-rich surface ideal for protecting CNC machined parts from wear and weather.

- Electroplating: By depositing metal layers such as nickel, chrome, or zinc onto parts, electroplating improves corrosion resistance and surface hardness while offering a polished look.

Thermal and Specialized Finishes

- Fire Polishing: A technique mostly used on plastics or glass, where heat is carefully applied to smooth the surface and give a glossy finish.

- Vapor Polishing: Similar to fire polishing but uses solvent vapors to gently melt the surface microscopically, resulting in a clear and smooth finish.

Each of these techniques offers unique benefits depending on material type, application, and budget. Choosing the right surface finishing method can significantly enhance your CNC machined parts’ performance and longevity.

Choosing the Right Surface Finish for Your CNC Project

Picking the right surface finish for your CNC project is key to getting the performance and look you want. Here’s what you need to consider:

Factors to Consider

- Material type: Different metals and plastics react differently to finishing processes. For example, anodizing works great on aluminum, while passivation is better for stainless steel.

- Functionality: Think about how the part will be used. Does it need extra corrosion resistance, improved wear, or better aesthetics?

- Surface roughness: Determine the finish level needed — some projects require a smooth polished look, while others may only need a bead blasting finish for texture.

- Budget and timeline: Certain finishes like electropolishing or chromate coating require more time and cost but offer superior results.

- Environmental exposure: If your parts will face harsh conditions, a durable coating such as powder coating or specialized treatments like chromate coating might be necessary.

Industry Specific Applications

Different industries have unique surface finishing needs:

- Aerospace and automotive: Often demand tight surface roughness control with finishes like wet sanding, polishing, or anodizing CNC parts for durability.

- Medical devices: Require ultra-clean, non-reactive finishes such as electropolishing metal or passivation stainless steel to meet hygiene standards.

- Electronics: Depend on coatings like electroplating or chromate coating aluminum for electrical conductivity and corrosion protection.

- Consumer products: Usually focus on aesthetic finishes like powder coating machining or bead blasting finish to improve look and feel.

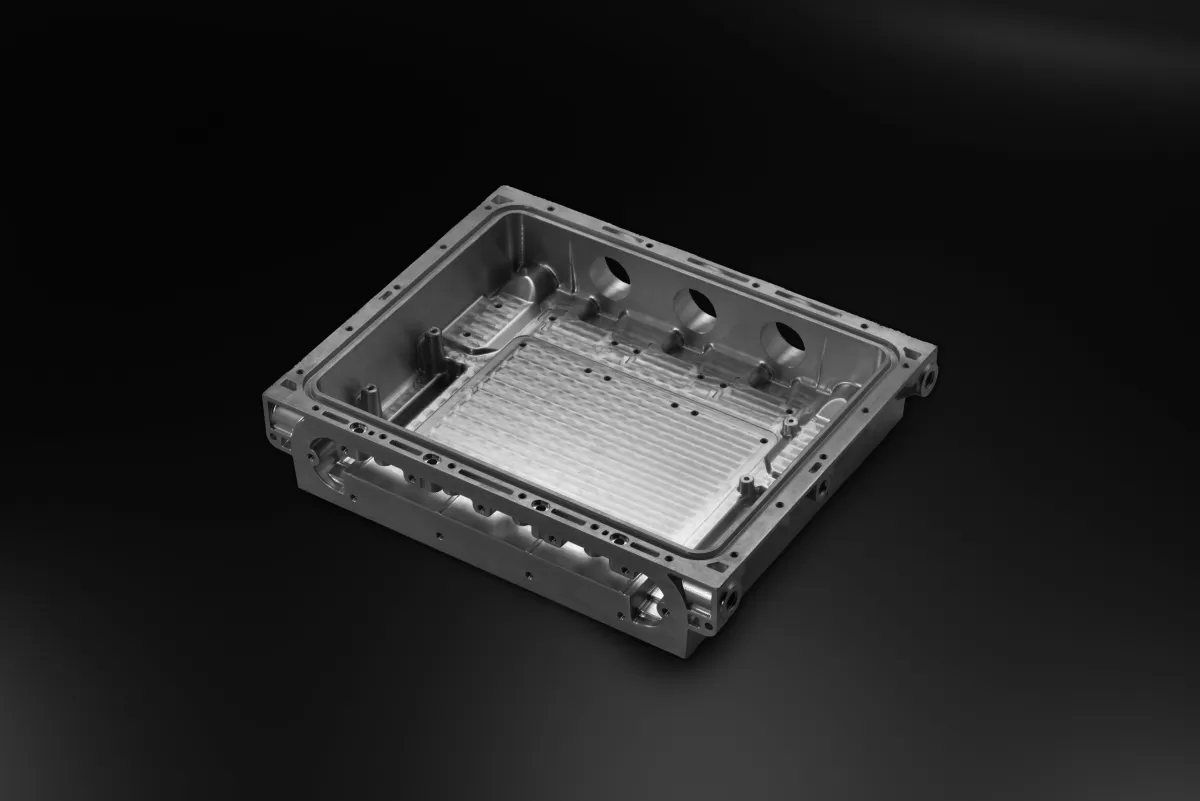

HYCNC’s Tailored Solutions

At HYCNC, we understand these nuances and offer customized surface finishing options to match your project needs. Whether you need grinding CNC components to prep the surface or advanced finishes like fire polishing for plastic parts, we’ve got you covered. Our team works closely with you to select the right finishing process that balances quality, cost, and delivery time — helping you bring your parts to the next level.

If you want to learn more about CNC surface finishing options and optimization, feel free to explore our services tailored for precision and reliability.

Optimizing CNC Machining for Better Surface Finishes

Getting the best surface finish starts right at the CNC machining stage. By optimizing your process, you can reduce the need for extensive finishing later and save time and cost. Here’s how to optimize your CNC machining for a smooth surface finish.

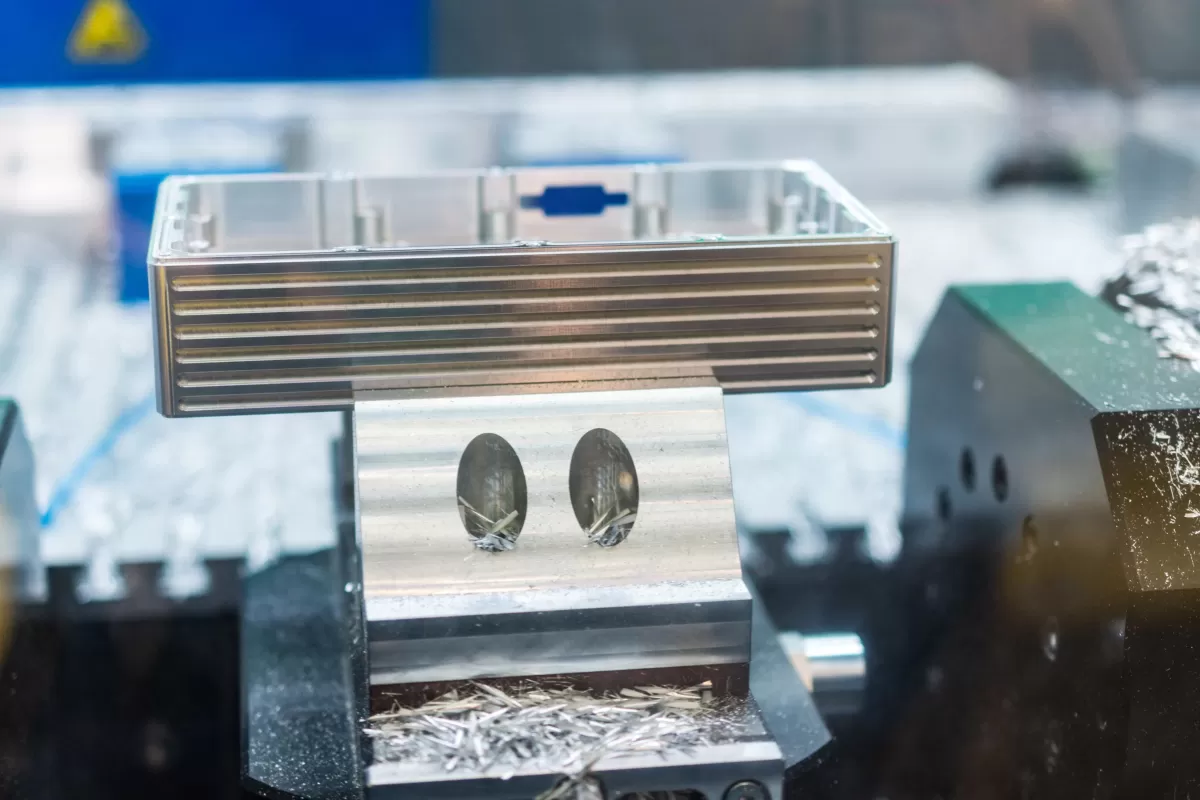

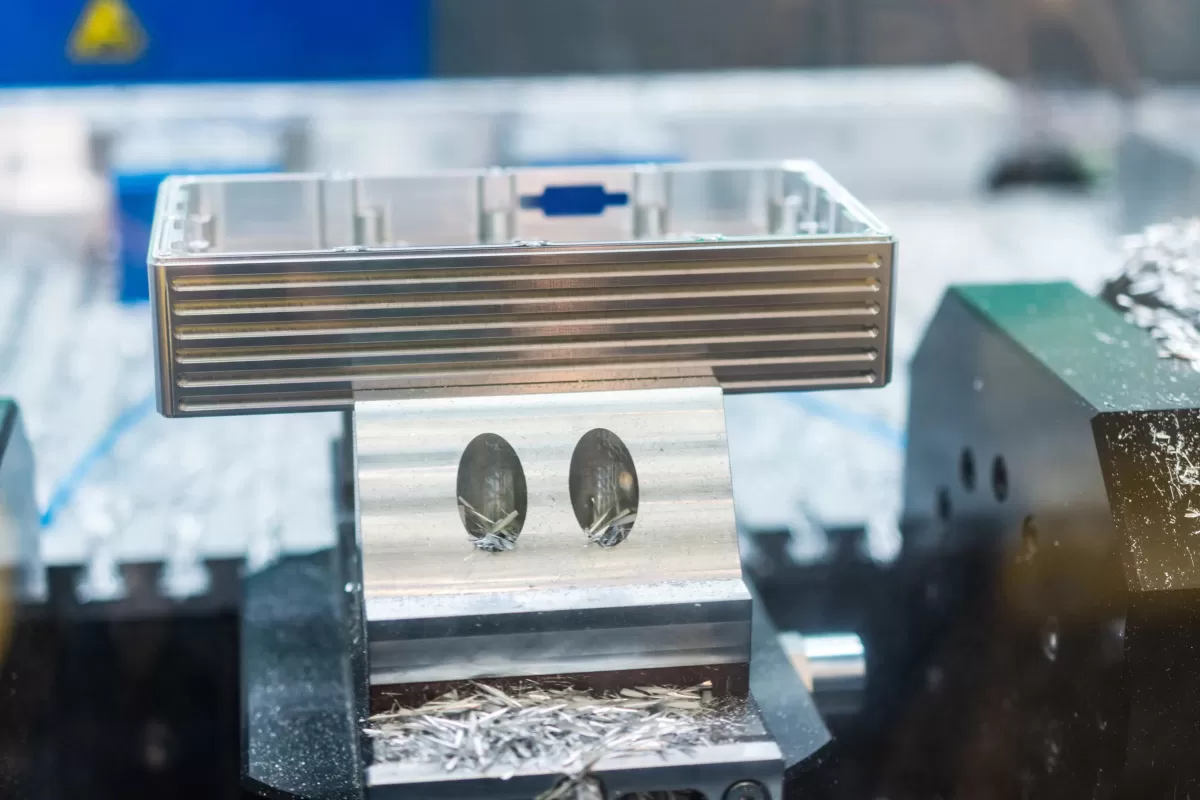

Pre Finishing Preparation

- Material Selection: Choose materials that machine well and respond nicely to finishing, like aluminum or stainless steel.

- Tool Condition: Sharp, well-maintained tools cut cleaner and reduce surface roughness.

- Clean Setup: Make sure your workpiece is secure and free from contaminants to avoid defects.

Machining Parameters

- Feed Rate and Speed: Slower feed rates and higher spindle speeds often improve surface finish by reducing tool marks.

- Tool Path Strategy: Use consistent, smooth tool paths. Avoid sudden changes in direction.

- Depth of Cut: Smaller depths of cut minimize vibrations and leave finer surfaces.

- Coolant Use: Proper coolant reduces heat and improves finish by washing away debris.

Avoiding Common Defects

- Tool Wear: Replace worn tools promptly to prevent rough surfaces.

- Chatter and Vibration: Adjust speeds or use dampening to control vibrations that cause surface imperfections.

- Inconsistent Feed: Ensure feed rates are steady to avoid uneven finishes.

Optimizing these factors during CNC machining helps reduce surface roughness naturally — leading to less reliance on heavy surface finishing processes later. For precise projects, tailoring these settings to your material and design will ensure your parts meet industry finish standards without adding unnecessary time or cost.

Benefits of Partnering with HYCNC for Surface Finishing

Choosing the right partner for your CNC surface finishing needs can make all the difference. Here’s why working with HYCNC stands out:

Expertise and Technology

At HYCNC, we combine years of experience with advanced technology to deliver top-quality surface finishing. Whether you need grinding CNC components, anodizing CNC parts, or powder coating machining, our team knows the best processes to meet your exact requirements.

Quality Assurance

Quality is our priority. Every surface finishing job undergoes strict inspections to ensure it meets industry standards and your specifications. This means your parts will have consistent surface roughness and durability — no surprises.

Fast Delivery and Customization

We understand the demands of tight schedules. HYCNC offers quick turnaround times without sacrificing quality. Plus, we customize finishes, from bead blasting finish to electropolishing metal surfaces, ensuring your project gets the perfect look and performance.

Cost Effective Solutions

With efficient processes and expert craftsmanship, HYCNC provides high-value surface finishing that fits your budget. You get reliable results without excessive costs, making your investment in CNC machining and finishing worthwhile.

Partnering with HYCNC guarantees quality, speed, and tailored solutions for all your surface finishing needs.

FAQs

What is surface finishing in CNC machining?

Surface finishing refers to the process of improving the surface quality of CNC machined parts. It enhances appearance, protects against corrosion, and improves performance by reducing surface roughness.

How do I choose the right surface finish for my CNC project?

Consider factors like the material, the part’s end use, environmental conditions, and budget. For example, anodizing is great for aluminum parts needing corrosion resistance, while powder coating offers durable color and protection.

Can surface finishing fix defects from CNC machining?

Yes, certain surface finishing methods like grinding and polishing can smooth out imperfections and improve surface roughness after machining.

What are the most common surface finishing techniques for CNC parts?

Key techniques include grinding, polishing, bead blasting, anodizing, electropolishing, passivation, and powder coating. Each serves different needs depending on the material and desired finish.

Is electropolishing suitable for stainless steel parts?

Absolutely. Electropolishing stainless steel removes surface contaminants and improves corrosion resistance, making it ideal for medical, food, or cleanroom applications.

How does bead blasting affect the finish of CNC parts?

Bead blasting creates a uniform matte texture, removes surface imperfections, and preps parts for coatings like powder coating or anodizing.

What is the difference between powder coating and electroplating?

Powder coating applies a durable, colored finish using a powder and heat, while electroplating deposits a thin metal layer to improve wear resistance and appearance.

Why should I choose a professional CNC service like HYCNC for surface finishing?

HYCNC offers expertise, cutting-edge technology, and tailored solutions ensuring precise, high-quality surface finishes with fast turnaround and cost-effective pricing suited for U.S. customers.